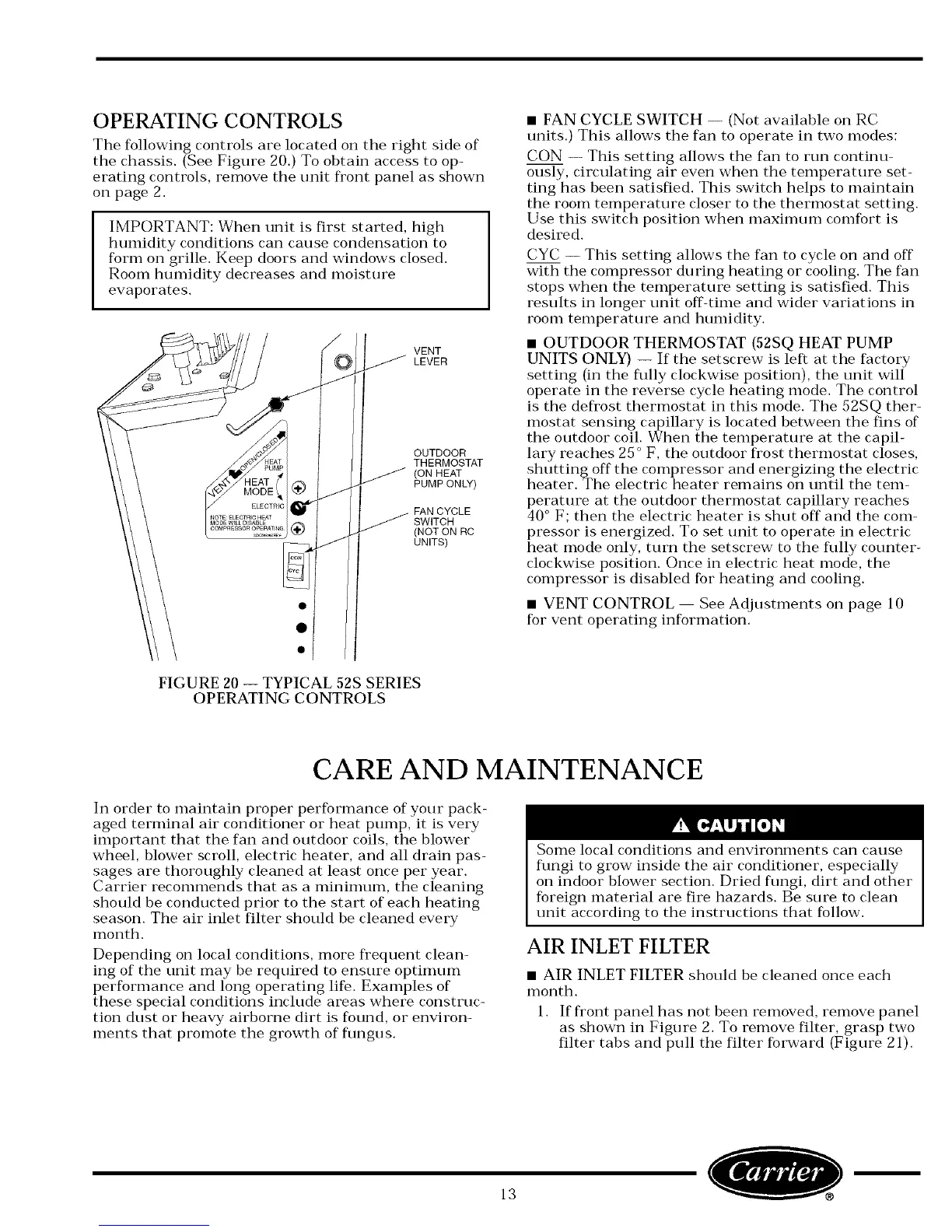

OPERATING CONTROLS

The following controls are located on the right side of

the chassis. (See Figure 20.) To obtain access to op-

erating controls, remove the unit fl'ont panel as shown

on page 2.

IMPORTANT: When unit is first started, high

humidity conditions can cause condensation to

form on grille. Keep doors and windows closed.

Room humidity decreases and moisture

evaporates.

!o/>VE ,

LEVER

_TII T

FIGURE 20 -- TYPICAL 52S SERIES

OPERATING CONTROLS

• FAN CYCLE SWITCH -- (Not available on RC

units.) This allows the fan to operate in two modes:

CON -- This setting allows the fan to run continu-

ously, circulating air even when the temperature set-

ting has been satisfied. This switch helps to maintain

the room temperature closer to the thermostat setting.

Use this switch position when maximum comfort is

desired.

CYC -- This setting allows the fan to cycle on and off

with the compressor du ring heating or cooling. The fan

stops when the temperature setting is satisfied. This

results in longer unit off-time and wider variations in

room temperature and humidity.

• OUTDOOR THERMOSTAT (52SQ HEAT PUMP

UNITS ONLY) -- If the setscrew is left at the factory

setting (in the flflly clockwise position), the unit will

operate in the reverse cycle heating mode. The control

is the defi'ost thermostat in this mode. The 52SQ ther-

mostat sensing capillary is located between the fins of

the outdoor coil. When the temperature at the capil-

lary reaches 25 ° F, the outdoor fi'ost thermostat closes,

shutting off the compressor and energizing the electric

heater. The electric heater remains on until the tem-

perature at the outdoor thermostat capillary reaches

40 ° F; then the electric heater is shut off and the com-

pressor is energized. To set unit to operate in electric

heat mode only, turn the setscrew to the flflly counter-

clockwise position. Once in electric heat mode, the

compressor is disabled for heating and cooling.

• VENT CONTROL See Adjustments on page 10

for vent operating infl)rmation.

CARE AND MAINTENANCE

In order to maintain proper performance of your pack-

aged terminal air conditioner or heat pump, it is very

important that the fan and outdoor coils, the blower

wheel, blower scroll, electric heater, and all drain pas-

sages are thoroughly cleaned at least once per year.

Carrier recommends that as a minimum, the cleaning

should be conducted prior to the start of each heating

season. The air inlet filter should be cleaned every

month.

Depending on local conditions, more fi'equent clean-

ing of the unit may be required to ensure optimum

performance and long operating life. Examples of

these special conditions include areas where construc-

tion dust or heavy airborne dirt is found, or environ-

ments that promote the growth of flmgus.

Some local conditions and environments can cause

flmgi to grow inside the air conditioner, especially

on indoor blower section. Dried flmgi, dirt and other

foreign material are fire hazards. Be sure to clean

unit according to the instructions that follow.

AIR INLET FILTER

• AIR INLET FILTER should be cleaned once each

month.

1. If fi'ont panel has not been removed, remove panel

as shown in Figure 2. To remove filter, grasp two

filter tabs and pull the filter forward (Figure 21).

13

O m

Loading...

Loading...