After fully assembling the vent connector to the furnace flue collar,

securely fasten the vent connector to the collar with 2 field-

supplied, corrosion-resistant, sheet metal screws located 180

degrees apart and midway up the collar.

The horizontal portion of the venting system shall maintain a

minimum of 1/4-in. upward slope per linear ft and it shall be

rigidly supported every 5 ft or less with hangers or straps to ensure

that there will be no movement after installation.

Step 9—Start-Up, Adjustment, and Safety Check

GENERAL

The furnace must have a 115-v power supply properly connected

and grounded. Correct polarity must be maintained to enable gas

heating operation.

The gas service pressure must not exceed 0.5 psig (14-in. wc), and

be no less than 0.16 psig (4.5-in. wc).

Thermostat wire connections at R and W/W1 are the minimum

required for gas heating operation. W2 must be connected for

2-stage heating thermostats. C

OM, Y/Y2, and G are required for

cooling, heat pumps, and some other thermostats. Follow manu-

facturer’s instructions supplied with thermostat. These must be

made at 24-v terminal block on control. (See Fig. 10.)

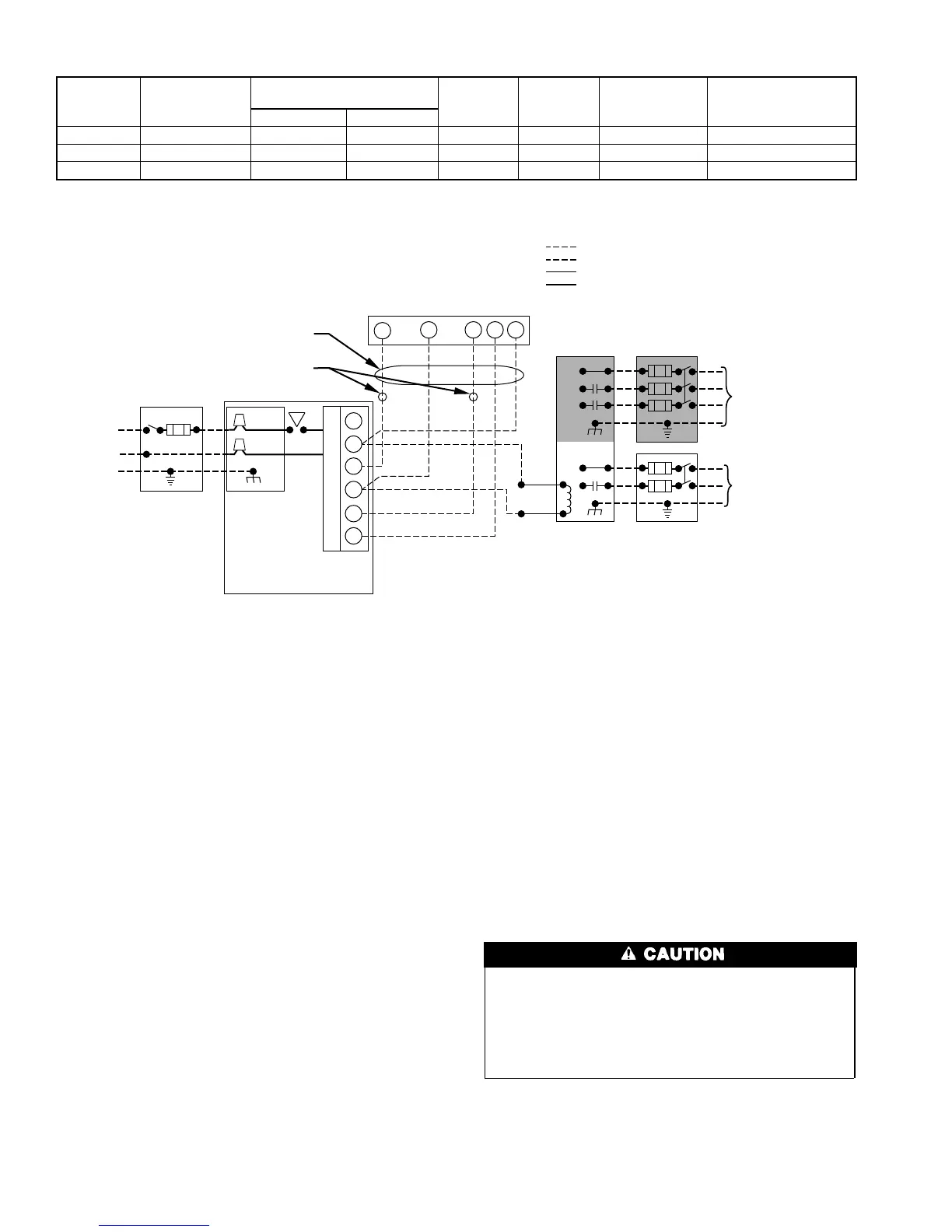

This furnace can be installed with either single-stage heating or

2-stage heating thermostat.

For single-stage thermostats, connect thermostat W to W/W1 at

furnace control terminal block. (See Fig. 11.) For single-stage

thermostats the control determines, based on length of previous

heating on and off cycles, when to operate in low- and high-gas

heat for optimum comfort. Setup Switch-2 (SW-2) must be in the

factory-shipped OFF position. See Fig. 13 and Tables 6 and 7 for

setup switch information.

If 2-stage heating thermostat is to be used, move SW-2 to ON

position at end of furnace installation. This overrides built-in

control process for selecting high and low stage and allows 2-stage

thermostat to select gas heating modes. The W2 from thermostat

must be connected to W2 on furnace control terminal block. (See

Fig. 12.)

Before operating furnace, check each manual reset switch for

continuity. If necessary, press and release button to reset switch.

This furnace is equipped with 2 manual reset limit switches in

gas control area. The switches will open and shut off power

to gas valve if a flame rollout or an overheating condition

occurs in gas control area. DO NOT bypass switches. Correct

inadequate combustion air supply, component failure, re-

stricted flue gas passageway before resetting switches.

SEQUENCE OF OPERATION

Using the schematic diagram follow sequence of operation through

different modes. (See Fig. 14.) Read and follow wiring diagram

very carefully.

Table 5—Electrical Data

UNIT

SIZE

VOLTS—

HERTZ—

PHASE

OPERATING

VOLTAGE RANGE

MAX

UNIT

AMPS

MIN

WIRE

GAGE

MAX WIRE

LENGTH

FT‡

MAXIMUM

FUSE OR

CKT BKR AMPS†

Max* Min*

060-12 115—60—1 127 104 10.5 14 35 15

080-16 115—60—1 127 104 14.2 14 26 15

100-20 115—60—1 127 104 17.9 12 32 20

* Permissible limits of the voltage range at which the unit will operate satisfactorily.

† Time-delay fuse is recommended.

‡ Length shown is as measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

Fig. 11—Heating and Cooling Application Diagram With 1-Stage Thermostat and 1-Stage Condensing Unit

A97443

115-V FUSED

DISCONNECT

SWITCH

(WHEN REQUIRED)

JUNCTION

BOX

CONTROL

BOX

24-V

TERMINAL

BLOCK

TWO-WIRE

HEATING-

ONLY

FIVE

WIRE

1-STAGE THERMOSTAT TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

FURNACE

COM

R

WYRG

C

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

WHT

BLK

WHT

BLK

W/W1

W2

Y/Y2

G

NOTES: 1. Connect Y-terminal as shown for proper operation.

2. Some thermostats require a "C" terminal connection as shown.

3. If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire.

10

Loading...

Loading...