70

Table 2 1 (Continued) -- Orifice Size a nd Manifold Pressure (in. w.c.) for Gas Input Rate

26,000 BTUH ONLY

650

43 1.7 43 1.8 42 1.5 42 1.6

7001 675 44 1.8

43 1.7 43 1.7 43 1.8

(2134) 700 44 1.7 44 1.8 44 1.8

43 1.7

725 44 1.6 44 1.7 44 1.7 44 1.8

750 44 1.5 44 1.5 44 1.6 44 1.6

8000 775 44 1.4 44 1.4 44 1.5 44 1.5

(2438) 800 44 1.3 44 1.4 44 1.4 44 1.4

825 44 1.2 44 1.3 44 1.3 44 1.4

625

43 1.7 43 1.8 43 1.8 42 1.6

8001 650 44 1.8

43 1.7 43 1.7 43 1.8

(2439) 675 44 1.7 44 1.8 44 1.8

43 1.6

700 44 1.6 44 1.6 44 1.7 44 1.7

725 44 1.5 44 1.5 44 1.6 44 1.6

9000 750 44 1.4 44 1.4 44 1.5 44 1.5

(2743) 775 44 1.3 44 1.3 44 1.4 44 1.4

9001 600

43 1.7 43 1.8 43 1.8 42 1.6

(2744) 625 44 1.8

43 1.6 43 1.7 43 1.7

650 44 1.7 44 1.7 44 1.8 44 1.8

675 44 1.6 44 1.6 44 1.7 44 1.7

10000 700 44 1.4 44 1.5 44 1.5 44 1.6

(3048) 725 44 1.3 44 1.4 44 1.4 44 1.5

* Orifice numbers shown in BOLD are factory-installed.

U.S.A. Only

to

U.S.A. Only

to

U.S.A. Only

to

ORIFICE SIZE* AND MANIFOLD PRESSURE (IN WC) FOR GAS INPUT RATE

TABULATED DATA BASED ON 13,000 BTUH PER BURNER, DERATED 2%/1000 FT (305M) ABOVE SEA LEVE

A150572

Check Inlet Gas Pr essur e

The inlet gas pressure must be checked with the furnace operating

in maximum heat. This is necessary to make sure the inlet gas

pressure does not fall below the minimum pressure of 4.5 in. w.c.

1. Make sure the gas supply is turned off to the furnace and at

the electric switch on the gas valve.

2. Loosen set screw on inlet tower pressure tap no more than

one full turn with a 3/32--in. hex wrench or remove the

1/8--in. NPT plug from the inlet pressure tap on the gas

valve.

3. Connect a manometer to the inlet pressure tap on gas valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper R and W thermostat connections at the furnace

control board.

8. When main burners ignite, confirm inlet gas pressure is

between 4.5 in. w.c. (1125 Pa) and 13.6 in. w.c. (3388 Pa).

9. Remove jumper across thermostat connections to terminate

call for heat. Wait until the blower off delay is completed.

10. Turn furnace gas valve electric switch to OFF position.

11. Turn gas supply manual shutoff valve to OFF position.

12. Turn off furnace power supply.

13. Remove manometer from the inlet pressure tap of the gas

valve.

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Inlet pressure tap set screw must be tightened and 1/8--in. NPT

pipe plug must be installed to prevent gas leaks.

!

WARNING

14. Tighten set screw on inlet tower pressure tap with 3/32--in.

hex wrench, or if 1/8--in. NPT plug was removed, apply

pipe dope sparingly to end of plug and re--install in the gas

valve.

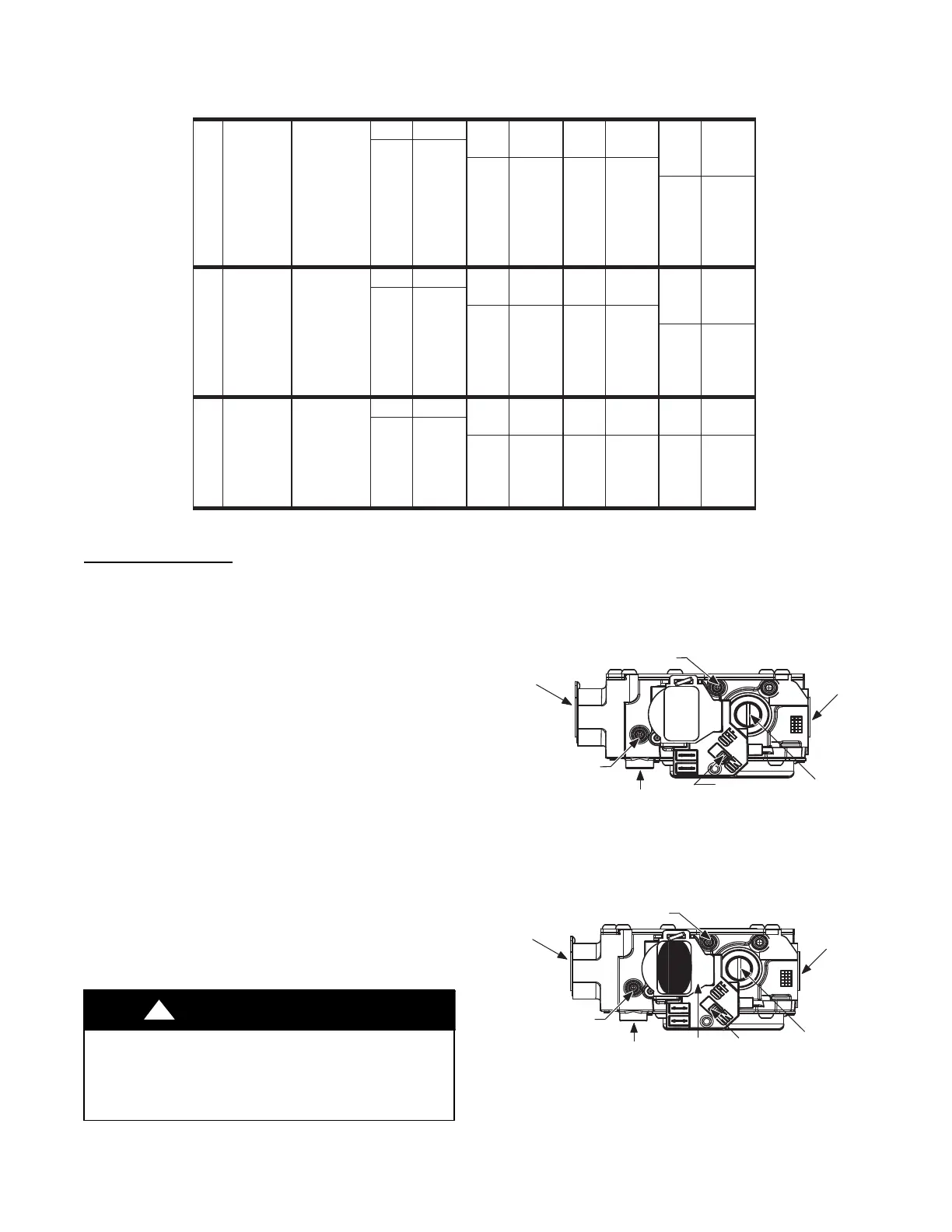

ON/OFF SWITCH

1/8” NPT INLET

PRESSURE TAP

REGULATOR SEAL CAP

(REGULATOR ADJ.

UNDER CAP)

1/2” NPT

OUTLET

MANIFOLD PRESSURE TAP

SET SCREW: 3/32” HEX HEAD

ACCEPTS 5/16” HOSE CONNECTION

OUTP

INP

VENT

1/2” NPT

INLET

INLET PRESSURE

TAP SET SCREW:

3/32” HEX HEAD

ACCEPTS 5/16”

HOSE CONNECTION

Representative drawing only, some models may vary in appearance.

A170140

Standard Capacity Gas Valve with Tower Pressure Ports

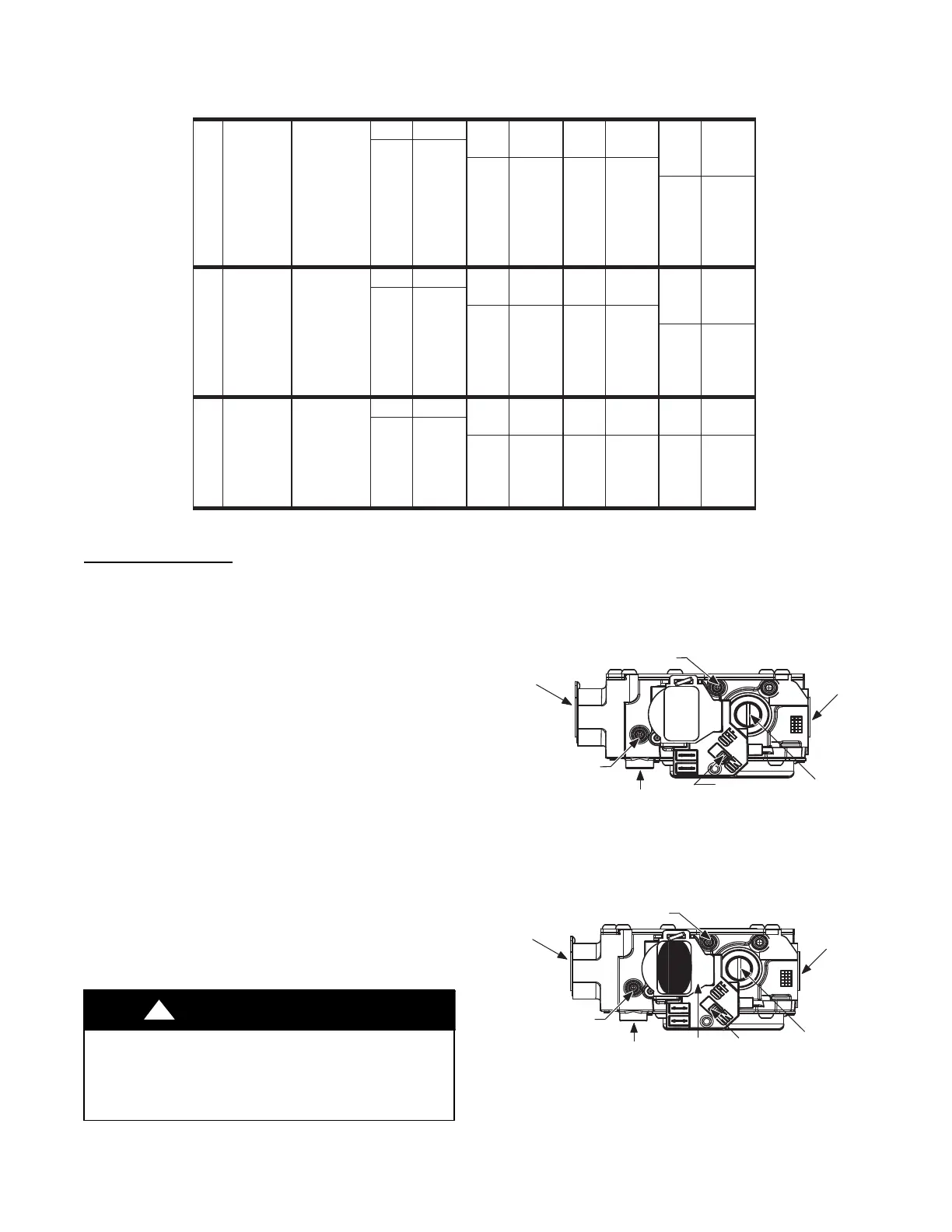

1/8” NPT INLET

PRESSURE TAP

REGULATOR SEAL CAP

(REGULATOR ADJ.

UNDER CAP)

1/2” NPT

OUTLET

MANIFOLD PRESSURE TAP

SET SCREW: 3/32” HEX HEAD

ACCEPTS 5/16” HOSE CONNECTION

OUTP

INP

VENT

1/2” NPT

INLET

INLET PRESSURE

TAP SET SCREW:

3/32” HEX HEAD

ACCEPTS 5/16”

HOSE CONNECTION

Representative drawing only, some models may vary in appearance.

Green Label

Black Text

ON/OFF

SWITCH

1.5”

W.C

.

White Label

Black Text

A170118

26,000 BTUH Low Capacity Gas Valve with Tower Pressure

Ports

Fig. 60 -- Gas Valves

Loading...

Loading...