NOTE:

Units equipped with speed regulators (30RB/30RQ option 6B,

12, 15LS, 28, 116V, 116W, 116X, 116Y).

If the air temperature is below -10 °C and the unit has been

deenergised for more than 4 hours, it is necessary to wait

two hours after the unit has been switched on again to allow

the regulator to warm up.

7.2 - Minimum heat transfer uid ow rate

(units without factory-tted hydraulic module)

The minimum heat transfer uid ow rate for dierent unit sizes

is given in the tables in paragraph "Water type heat exchanger

ow rate".

It is determined in order to allow sucient exchange and prevent

the risk of excessive fouling.

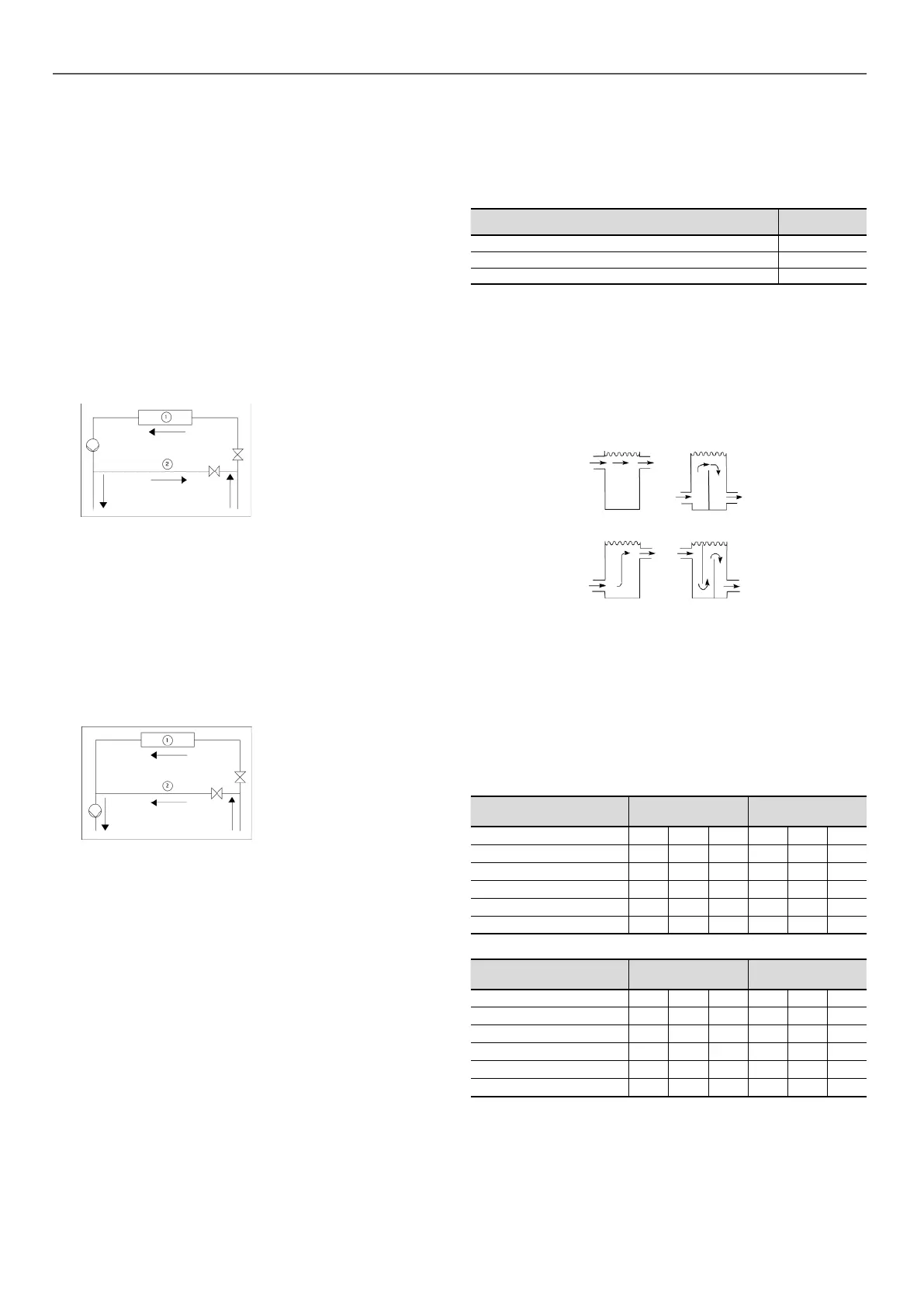

If the system ow rate is less than the unit's minimum ow rate,

the exchanger ow can be recirculated, as shown in the diagram.

Key

1 Water type heat exchanger

2 Recirculation

7.3 - Maximum heat transfer uid ow rate

(units without factory-tted hydraulic module)

The maximum heat transfer uid ow rate for dierent unit sizes

is given in the tables in paragraph "Water type heat exchanger

ow rate".

This is limited by the permitted exchanger pressure drop. In

addition, there must be a minimum Delta T of 3 K, which

corresponds to a ow rate of 0.09 l/s per kW.

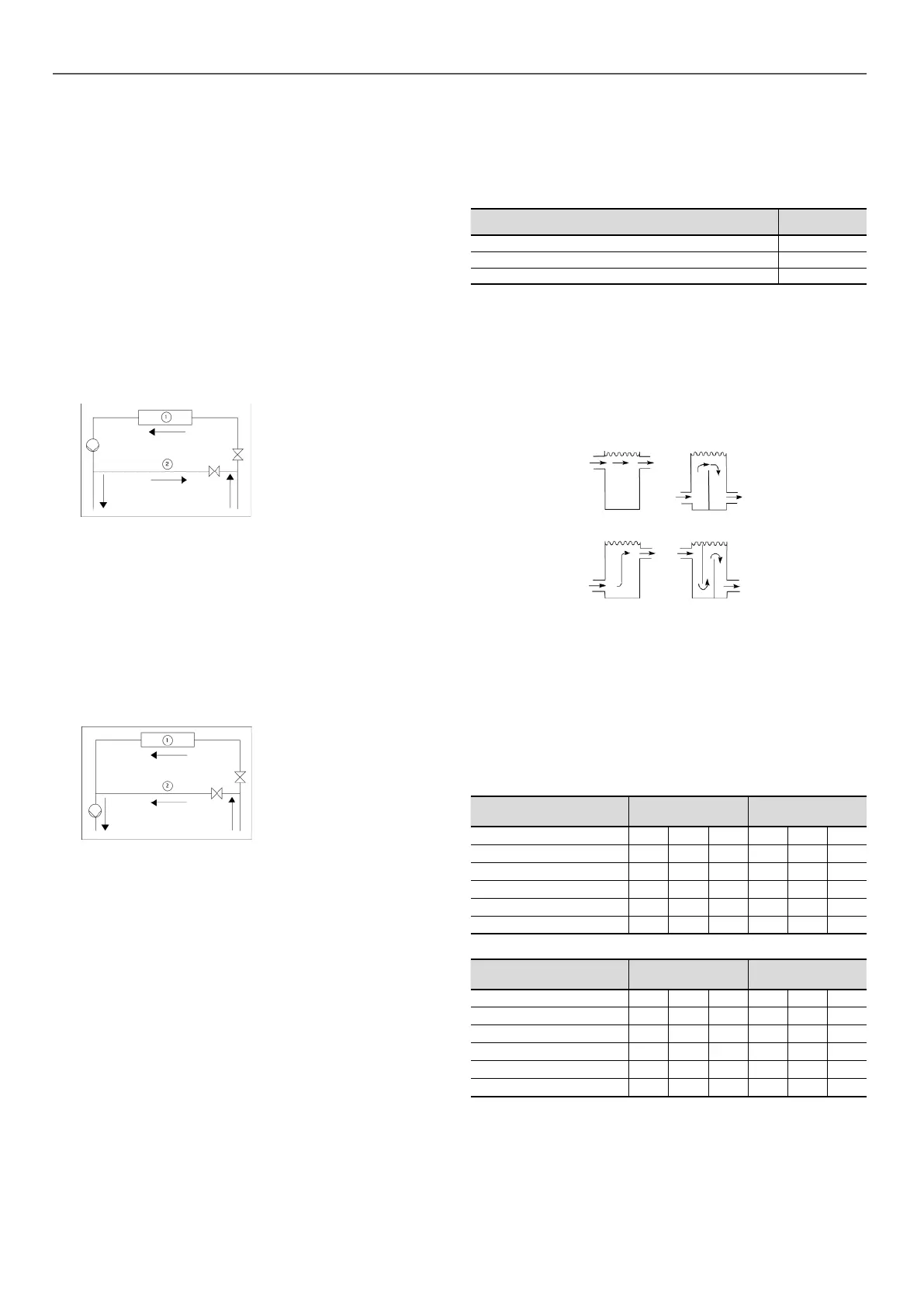

If the system ow rate exceeds the unit's maximum value, it can

be bypassed as shown in the diagram.

Key

1 Water type heat exchanger

2 Bypass

7.4 - Variable ow water type heat exchanger

(units without factory-tted hydraulic module)

A variable water heat exchanger ow can be used in standard

units. The ow rate must be higher than the minimum ow given

in the table of permissible ow rates and must not vary by more

than 10% per minute.

If the ow rate changes more rapidly, the system's water volume

should be increased and reach a value of at least 6.5 litres of water

per kW.

7.5 - Minimum system water volume

Whichever system, water volume for the water loop (to be provided

between the unit and any customer valves outside the machine)

is given by the formula

Volume = Cap (kW) x N litres

Application N

Air conditioning – cooling 2,5

Air conditioning – heating 3,0 - 8,0

(1)

Industrial process type cooling 6,5

(1) Depending on the unit capacity - minimum water loop volume 1300 l

Where "Cap" represents the cooling or heating capacity (kW)

under the installation's nominal operating conditions. This volume

is necessary for stable operation. It may be necessary to add a

buer water tank to the circuit in order to achieve the minimum

volume. The tank must itself be internally baed in order to ensure

proper mixing of the liquid (water or brine). Refer to the examples

below.

Connection to a buer tank

CorrectIncorrect

Incorrect Correct

7.6 - Maximum system water volume

Units with a hydraulic module may include an expansion vessel

which limits the volume in the water loop.

The table below gives the maximum loop volume compatible with

the expansion vessel (for pure water or ethylene glycol depending

on the system's various concentrations and static pressures).

If this volume is less than the volume of the installed loop, then it

is necessary to add an extra expansion vessel within the system.

Product

040-080 without

buer tank

090-160 without

buer tank

Static pressure bar 1 2 3 1 2 3

Pure water l 597 398 199 1741 1161 580

10% EG l 471 314 157 1373 915 458

20% EG l 389 259 130 1135 757 378

30% EG l 348 232 116 1014 676 338

40% EG l 289 193 96 843 562 281

Product

040-080 without

buer tank

090-160 without

buer tank

Static pressure bar 1 2 3 1 2 3

Pure water l 896 597 299 1741 1161 580

10% EG l 706 471 235 1373 915 458

20% EG l 584 389 195 1135 757 378

30% EG l 522 348 174 1014 676 338

40% EG l 434 289 145 843 562 281

EG: Ethylene Glycol

7 - APPLICATION DATA

22

Loading...

Loading...