8 - WATER CONNECTIONS

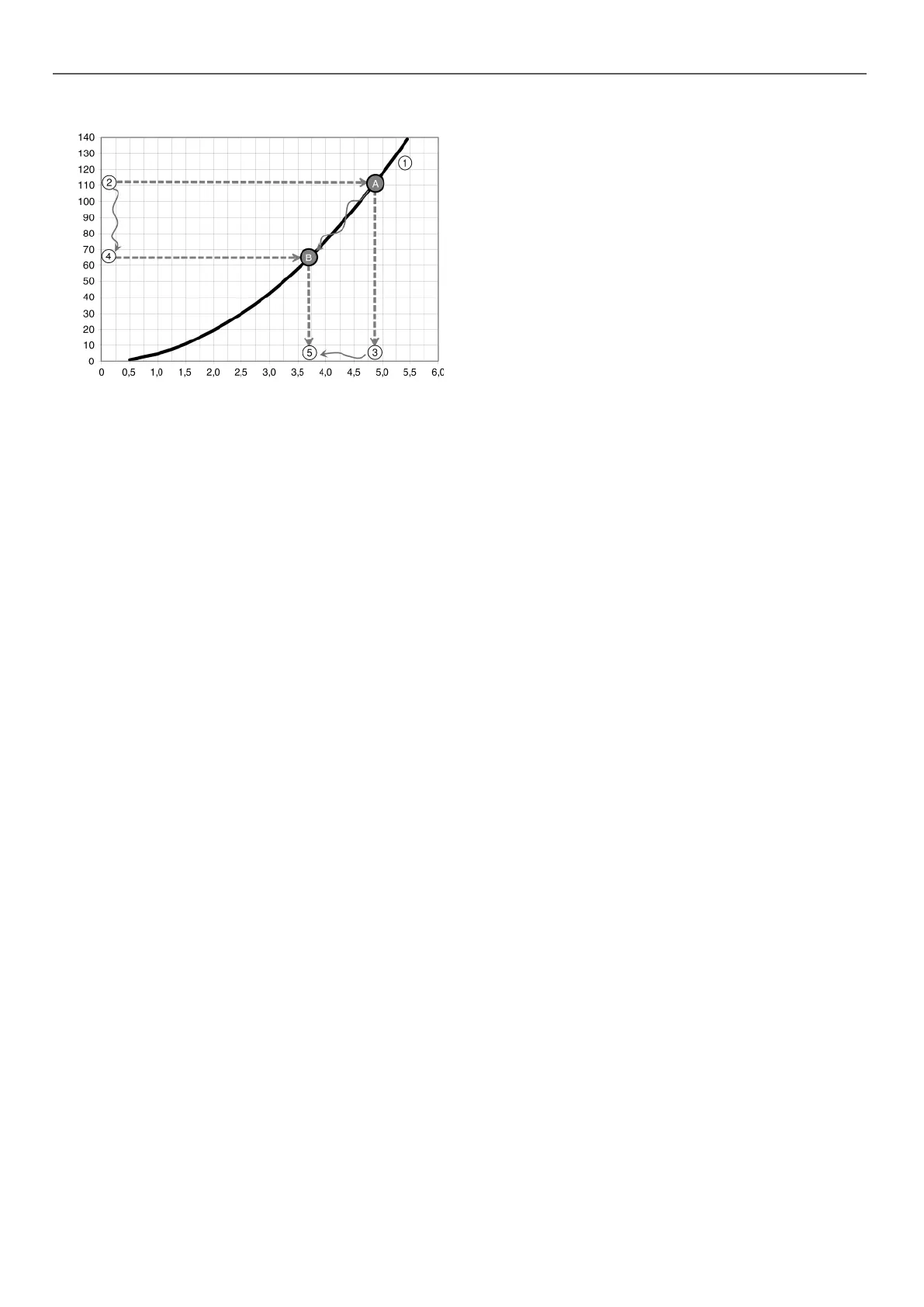

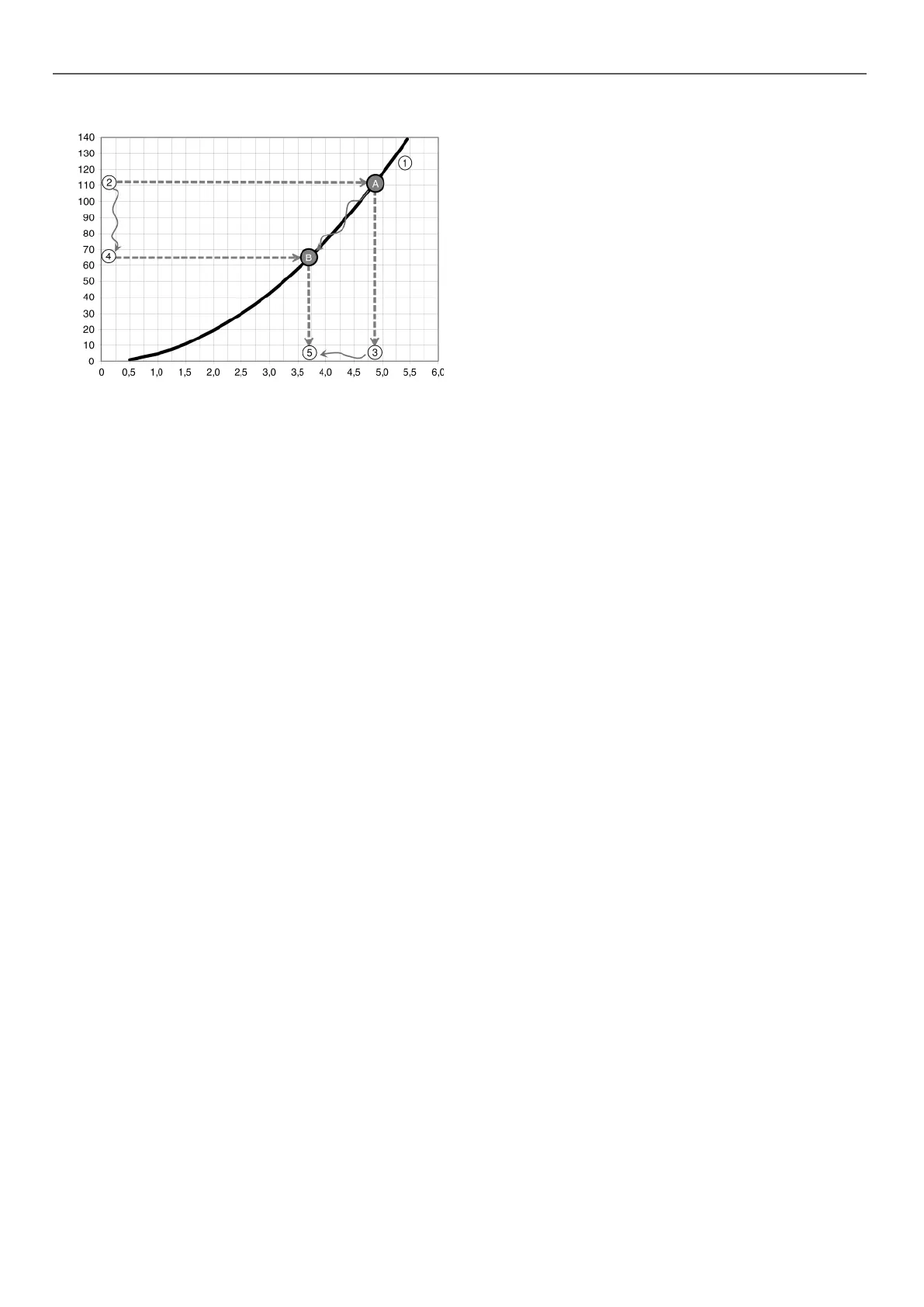

Example : Unit with specic nominal ow 3.7 l/s

Water ow rate, l/s

Pressure drop, kPa

Key

1 "Unit pressure drop (including internal water circuits)/ow rate" curve

2 With the valve open the pressure drop read (111 kPa) gives point A on the curve.

A Operating point reached with the valve open.

3 With the valve open, the ow rate achieved is 4.8 l/s: this is too high, and the

valve must be closed again.

4 If the valve is partially closed, the pressure drop read (65 kPa) gives point B on

the curve.

B Operating point reached with the valve partially closed.

5 With the valve partially closed, the ow rate achieved is 3.7 l/s: this is the required

ow rate and the valve is in the correct position.

8.4 - Units with hydraulic module and xed-

speed pump (for brine application only)

8.4.1 - General information

See chapter ‘‘Units without hydraulic module’’.

8.4.2 - Hydraulic circuit cleaning procedure

• Open all valves completely (item 19).

• Start up the system pump.

• Let the pump run for 2 hours continuously to ush the

system's hydraulic circuit (presence of contaminating

solids).

• Perform another reading.

• Compare this value to the initial value.

• A reducing value of the ow indicates that the lters on the

system need to be removed and cleaned. In this case, close

the Shut-o valves on the water inlet and outlet (item 19)

and remove the lters (items 20 and 1) after draining the

hydraulic part of the unit (item 6).

• Remove the air from the circuit (items 5 and 14).

• Repeat until all fouling is removed from the lter.

8.4.3 - Water ow rate adjustment procedure

Once the circuit is cleaned, read the ow value on the user

interface and compare it with design value for the system. If the

value of the ow is greater than the specied value, this indicates

that the overall pressure drop in the system is too low against the

available static pressure generated by the pump.

In this case, close the control valve and read the new ow rate

value. Repeat as necessary until a specific pressure drop

corresponding to the unit's nominal ow rate at the operation point

is achieved.

NOTE: If the network has an excessive pressure drop in

relation to the available static pressure delivered by the unit

pump, the nominal water ow cannot be obtained (lower

resulting ow) and the dierence in temperature between the

water inlet and outlet of the evaporator will be increased.

To reduce the system's hydraulic network pressure drop:

• Reduce the pressure drops of individual components

(bends, level changes, valves etc.) as much as possible

• Use the correct pipe diameter;

• Avoid extending the hydraulic systems when possible.

8.5 - Units with hydraulic module and variable-

speed pump - pressure dierential control

The system ow rate has not been set to a rated value. The ow

rate will be adjusted, by varying the pump speed, to maintain a

constant operating pressure dierential value dened by the user.

The pressure sensor at the unit outlet (item 10 in the typical

hydraulic circuit diagram) is used as the means of control.

The system calculates the measured pressure dierential value,

compares it with the setpoint value selected by the user and

modulates the pump speed accordingly. The result is:

• an increased ow rate, if a lower value than the set point is

measured,

• an decreased ow rate, if a higher value than the set point

is measured.

This ow rate variation is realised, observing the minimum and

maximum admissible unit ow rates as well as the minimum and

maximum pump supply frequency values.

The pressure dierential value maintained can in certain cases

be dierent from the set point value:

• If the set point value is too high (achieved for a higher ow

rate than the maximum value or a higher frequency than

the maximum value), the system settles at the maximum

ow rate or maximum frequency and this results in a lower

pressure dierential than the set point.

• If the set point value is too low (achieved for a lower ow

rate that the minimum value or a lower frequency than the

minimum value), the system settles at the minimum ow

rate or minimum frequency and this results in a higher

pressure dierential than the set point.

Contact Carrier Service to discuss the implementation of the

procedures set out below.

28

Loading...

Loading...