For suspected electrical failures, check for loose or faulty electrical

connections or defective fan-motor capacitor. Fan motor is

equipped with thermal overload device in motor windings which

may open under adverse operating conditions. Allow time for

motor to cool so device can reset. Further checking of motor can

be done with an ohmmeter. Set scale onRX1position, check for

continuity between 3 leads. Replace motors that show an open

circuit in any of the windings. Place 1 lead of ohmmeter on each

motor lead. At same time, place other ohmmeter lead on motor

case (ground). Replace any motor that shows resistance to ground,

signs of arcing, burning, or overheating.

Step 11—Service Alarm Control Board

NOTE: If the proper night-setback thermostat is not used, the

service-alarm control will work, but there will be no light

indication on thermostat.

The service-alarm control provides immediate warning when

outdoor heat pump requires servicing. It turns on indoor

thermostat-malfunction light if compressor does not operate for

either heating or cooling. This enables owner to obtain timely

heat-pump service during heating season, reducing supplementary

electric heat costs, and during cooling season, reducing period of

heat discomfort.

The service alarm is an accessory device. Service alarm locks out

compressor under certain adverse operating conditions. System is

manually reset by shutting it off at thermostat subbase, then

turning it back on. If adverse condition is corrected, system

restarts.

One example of an adverse condition would be a system located in

a desert climate where high operating temperatures may cause

system to shut down on the high-pressure switch or on the

compressor internal overload.

Connect service alarm to outdoor-unit control-circuit-terminal

board. (See Fig. 25 and wiring diagram on unit.)

Connect all field line-power wires to unit in usual manner. Route

1 field line-power supply wire through metallic loop on bottom of

service alarm then to normal unit connection. Units with RLA of

less than 14 amps will require 2 passes through the metallic loop.

Refer to Fig. 25 or 26 for wiring connections for service alarm or

service alarm with solid-state cycle-protector accessories, when

used.

NOTE: The wire from the X terminal on the service alarm to L on

the outdoor terminal board, indoor terminal board, and thermostat

subbase is field supplied and wired when using defrost controls

HK32FA003 or HK32FA006. When defrost control CES0110063

or CES0130024 is used, field-supplied wire from X terminal on

service alarm to L on indoor thermostat subbase is required.

Service alarm requires 2 inputs.

1. It must sense a 24v input from thermostat. As thermostat calls

for heating or cooling, it supplies 24v to service alarm device.

2. A current transformer (or induction loop) similar to a

clamp-on ammeter senses current draw in the compressor

lead. Induction loop must sense a minimum current draw

when thermostat is calling for heating or cooling.

NOTE: On a single-phase compressor, induction loop senses

current in common leg. On a 3-phase compressor, induction loop

senses current in any 1 of the phases.

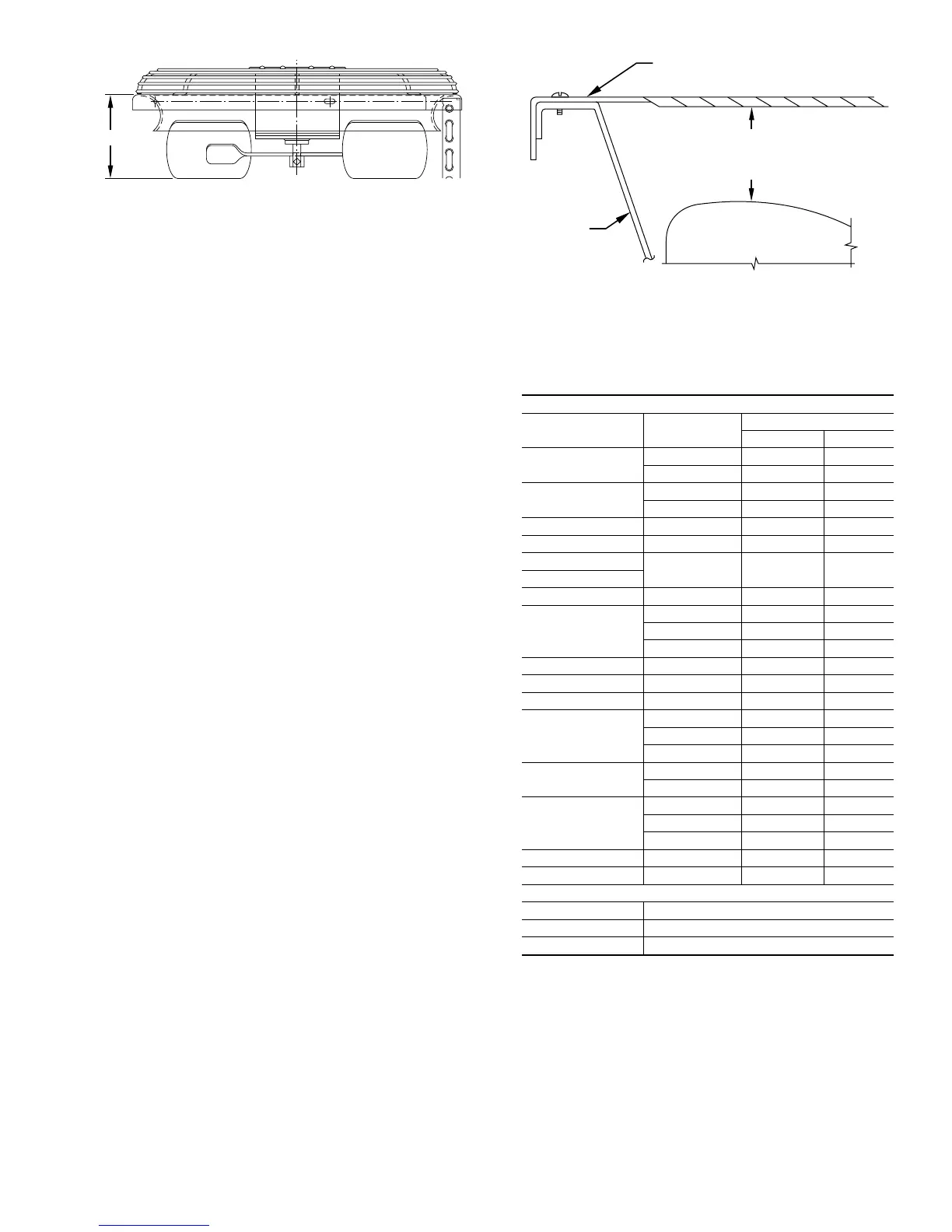

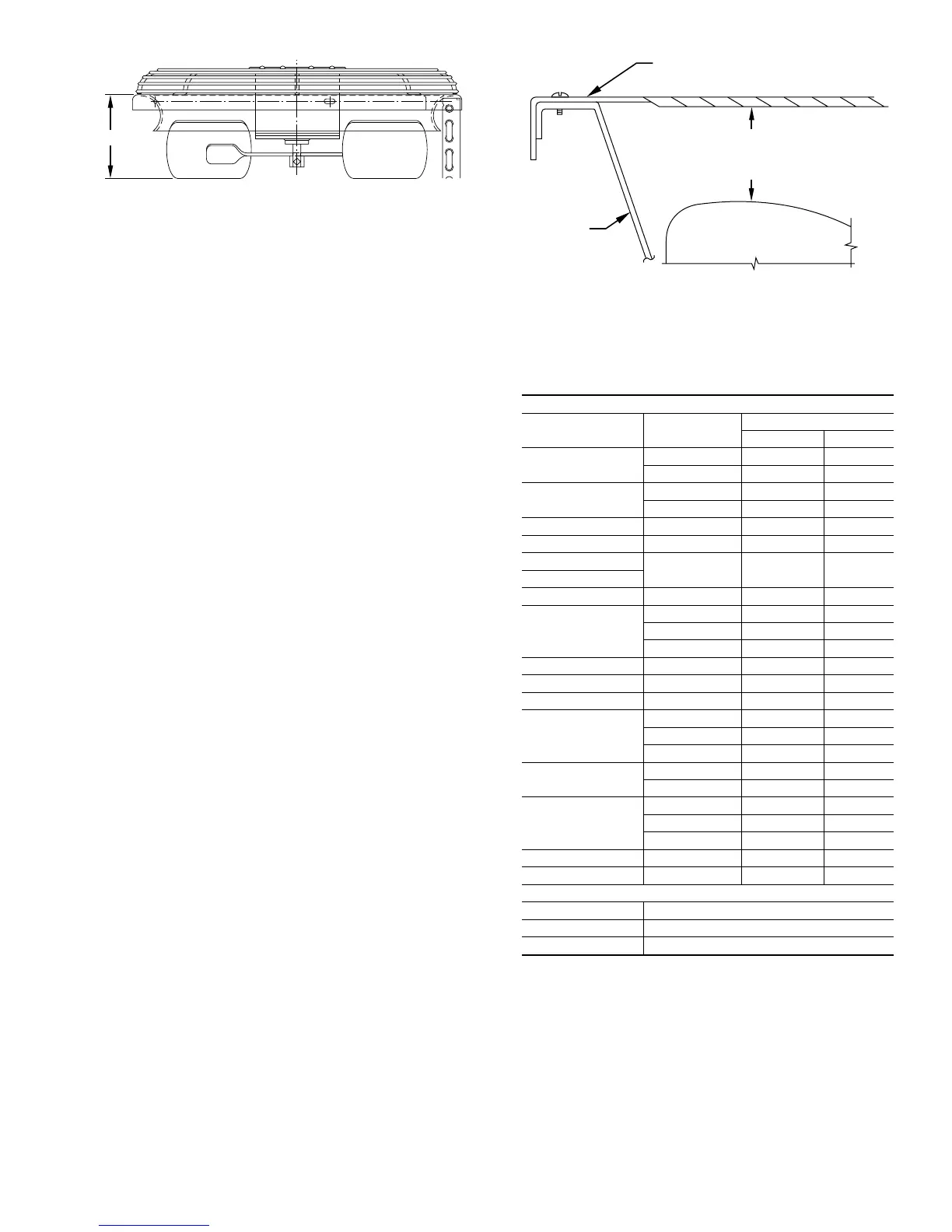

BASKET TOP

A

A91428

TOP COVER

FAN

ORIFICE

FAN BLADE

3 IN. SMALL & MEDIUM BASE UNITS

4 IN. LARGE BASE UNIT

FROM DISCHARGE LOUVER

TO TOP OF FAN BLADE

STAR BURST TOP

A88347

Fig. 24—Fan Position

Table 13—Fan Position

SILENCER SYSTEM™ AND BASKET TOP

Fan Motor

Part No.

Fan Blade

Part No.

Dimension A (In.)

Brookside Revcor

HC29GE208

LA01EB023 4-5/32 –

LA01EC019 5-1/8 –

HC31GE230/231

LA01EA026 4-5/8 –

LA01RA015 4-7/8 4-5/8

HC33GE208 LA01EW049 5-1/4 –

HC33GE232 LA01RA015 4-29/32 4-17/32

HC34GE231

LA01RA015 5-5/32 4-25/32

HC34GE460

HC35GE208 LA01EW048 4-15/16 –

HC35GE232

LA01EA025 5-7/8 –

LA01RA024 5-11/32 5-3/32

LA01RA026 5-9/16 4-11/16

HC37GE208 LA01EA025 6-1/8 6-1/8

HC37GE230 LA01EW042 6-5/32 6-1/8

HC38GE221 LA01EA031 7-25/32 –

HC39GE232

LA01EC018 5-11/16 –

LA01RA026 5-1/2 4-3/4

LA01EA036 5-9/16 –

HC39GE234

LA01EA024 5-3/32 4-27/32

LA01EC018 5-1/2 –

HC39GE461

LA01EA036 6-1/16 –

LA01EC018 6-1/4 –

LA01RA026 6-1/16 5-7/32

HC40GE230 LA01EA024 5-9/32 5-11/32

HC40GE461 LA01EA024 5-27/32 5-19/32

BASEPAN DIMENSIONS FOR STAR BURST TOP (IN.)

Small 22-1/2 x 26-3/16

Medium 30x33

Large 38-5/8 x 42-1/16

23

Loading...

Loading...