Step 4—Discharge Solenoid Valve

Some larger units equipped with scroll compressors contain a

solenoid valve that is piped between the discharge tube and suction

tube of the compressor. The purpose of the solenoid valve is to

cause a rapid pressure equalization around the compressor, thus

reducing the normal shutdown sound created by reverse rotation of

the scroll. The solenoid valve is normally closed and is wired

across high-voltage line 1 to load terminals of the contactor. (See

Fig. 18.) The solenoid-valve assembly also requires a check valve

piped in the discharge tube between the solenoid-valve tee and the

condenser coil, or reversing valve on heat pumps. The purpose of

the check valve is to prevent refrigerant from bypassing through

the solenoid valve into the suction tube when the unit cycles off.

MILLENNIUM SCROLL COMPRESSOR

Step 1—Features

The scroll compressor pumps refrigerant through the system by the

interaction of a stationary and an orbiting scroll. (See Fig. 29.) The

scroll compressor has no dynamic suction or discharge valves, and

it is more tolerant of stresses caused by debris, liquid slugging, and

flooded starts. The Millennium scroll varies from the Copeland

scroll in that the Millennium has a shutdown flapper valve located

between the scroll plates and the discharge head, whereas the

Copeland has a check device at the discharge connection after the

discharge head. The Copeland discharge head unloads when the

compressor shuts down. The scroll plate actually runs backwards

while it unloads.A1to3second unloading of refrigerant occurs.

The Millennium flapper valve eliminates the refrigerant unloading

by not allowing the discharge head to run backwards because of its

location. The Millennium scroll compressor uses Zerol 150 oil

with 3 percent Syn-O-Ad and is the only oil recommended for oil

recharge. See Table 14 for recharge requirements.

Step 2—Compressor Protection

Millennium scroll compressors are protected by an internal line-

break mounted on the motor windings. Internal protectors respond

to overcurrent and high temperature. These protectors are

automatic-reset devices containing a snap-action, bi-metal switch.

Step 3—Troubleshooting

Troubleshooting mechanical and electrical problems in a scroll

compressor is similar to a reciprocating compressor, except that a

scroll compressor should never be allowed to pump into a vacuum.

The scroll compressor is capable of pumping into a vacuum very

quickly, which could cause fusite arcing and compressor failure.

See Step 4 of Reciprocating Compressor section for removal and

replacement.

Step 4—Scroll-Compressor, 3–Phase Monitor

CES0130075 — PHASE MONITOR

This control is factory-installed on all 3–phase, scroll-compressor

models. (See Fig. 31 and 32.) On start-up, the control will energize

the pilot relay for 2 seconds. The monitor will check for correct

compressor rotation. If rotation is correct, unit will continue to run.

If rotation is incorrect, the control will break the 24–vac power at

the contactor and an LED light on the control will flash. If LED is

flashing, turn off power, reverse L1 and L3 field-power leads, and

restart unit. This control will check incoming power at every

restart.

OLYMPIA SERIES HORIZONTAL UNITS

Step 1—General

This family of units has horizontal airflow which allows for greater

installation flexibility. The blow-through design of the coil, along

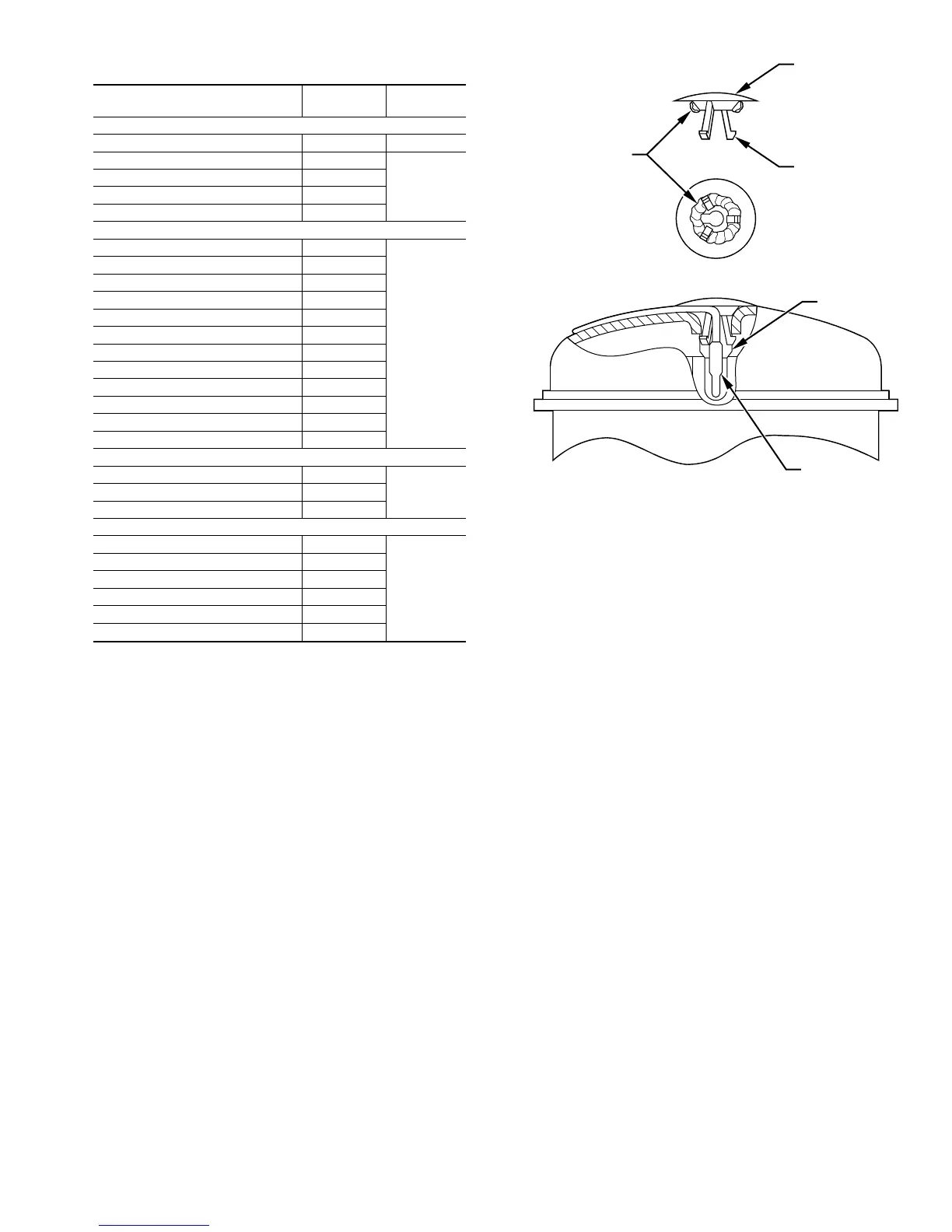

Table 14—Compressor Oil Recharge

COMPRESSOR MODEL

RECHARGE

(FL. OZ.)

OIL TYPE

Carlyle/Scroll

”J” Type 44 Suniso 3GS

SC, SRD450AC 34

Zerol 150

w/3 percent

Syn-O-Ad

SR 52

SRH482, SRY482 68

SRH602, SRY602 70

Copeland

CRG3, CRH3, CRJ3, CRK3, CRL3 51

Suniso 3GS

CRN5, CRP5, CRT5, CTH1, CTL1 66

CRC4, CRZ4 36

CR16K6 Through CR42K6 42

*ZR18K1 19

*ZR23K1, ZR28K1 24

*ZR34K1 30

*ZR40K1 34

*ZR49K1-PFV 56

*ZR49K2-TF5, ZR49K2-TFD 56

*ZR61K2-PFV 56

*ZR61K2-TF5, ZR61K2-TFD 66

Tecumseh

AV55 50

Suniso 3GSAW55 30

AG 60

Bristol

H23A 52

Suniso 3GS

H23B 37

H24A3, H24A4 47

H24A5 52

H25A, H26A 62

H25B, H26B, H29B 32

*Copeland scrolls are charged initially with Sontex 200LT white oil. Since this

oil is not commercially available, use 3GS.

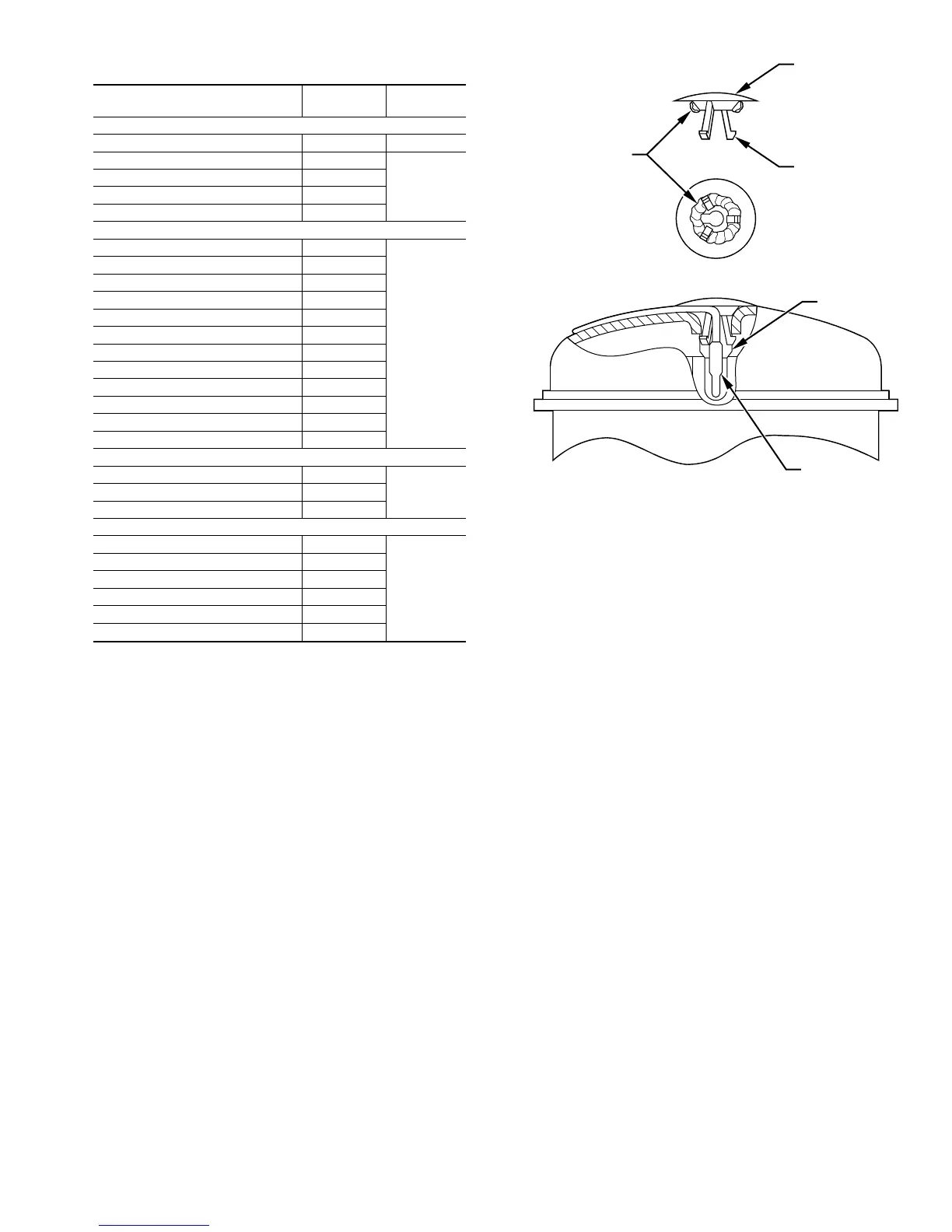

Fig. 30—Location of Discharge Thermostat

A90198

PLASTIC CAP

PRONG

BLUE SEALANT

GROMMET

THERMAL GREASE

THERMOSTAT

29

Loading...

Loading...