ROUBLESHOOTING

669224-R5

T

12

4.1 General Procedures

4.1-1 Truck System Requirements

• Truckhydraulicpressureshouldbewithintherange

showninSpecications,Section6.1.PRESSURE TO

THE ATTACHMENT MUST NOT EXCEED 2300 psi

(160 bar).

• Hydraulicowshouldbewithintherangeshownin

Specications,Section6.1

• Hydraulicuidsuppliedtotheattachmentmustmeet

therequirementsshowninSpecications,Section6.1.

4.1-2 Tools Required

Inadditiontoanormalselectionofmechanic'shandtools,

thefollowingarerequired:

• In-LineFlowMeterKit:

10GPM(37L/min)–CascadePartNo.671476

OR

20GPM(75L/min)–CascadePartNo.671477

• PressureGaugeKit:

5000psi(345bar)–CascadePartNo.671212

• Assortedttings,hosesandquick-disconnectcouplers,

asrequired.

4.1-3 Troubleshooting Chart

WARNING: Beforeservicingany

hydrauliccomponent,relievepressurein

thesystem.Turnthetruckoffandmove

thetruckauxiliarycontrolvalvesseveral

timesinbothdirections.

Aftercompletinganyserviceprocedure,testthe

attachmentthroughseveralcycles.Firsttestthe

attachmentemptytobleedanyairtrappedinthe

systemtothetrucktank.Thentesttheattachment

withaloadtobesureitoperatescorrectlybefore

returningtothejob.

Stayclearoftheloadwhiletesting.Donotraisethe

loadmorethan4in.(10cm)offtheoorwhiletesting.

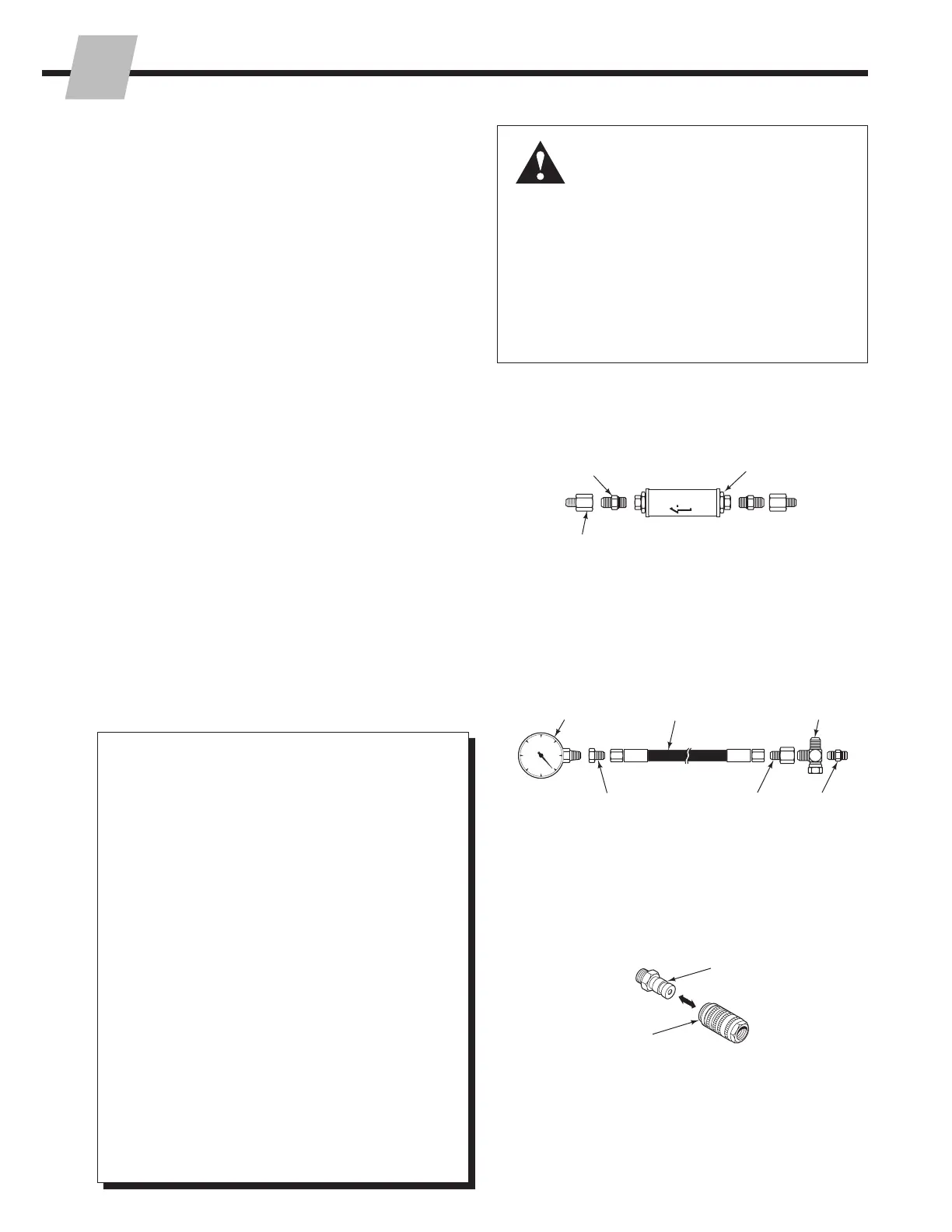

GA0013.eps

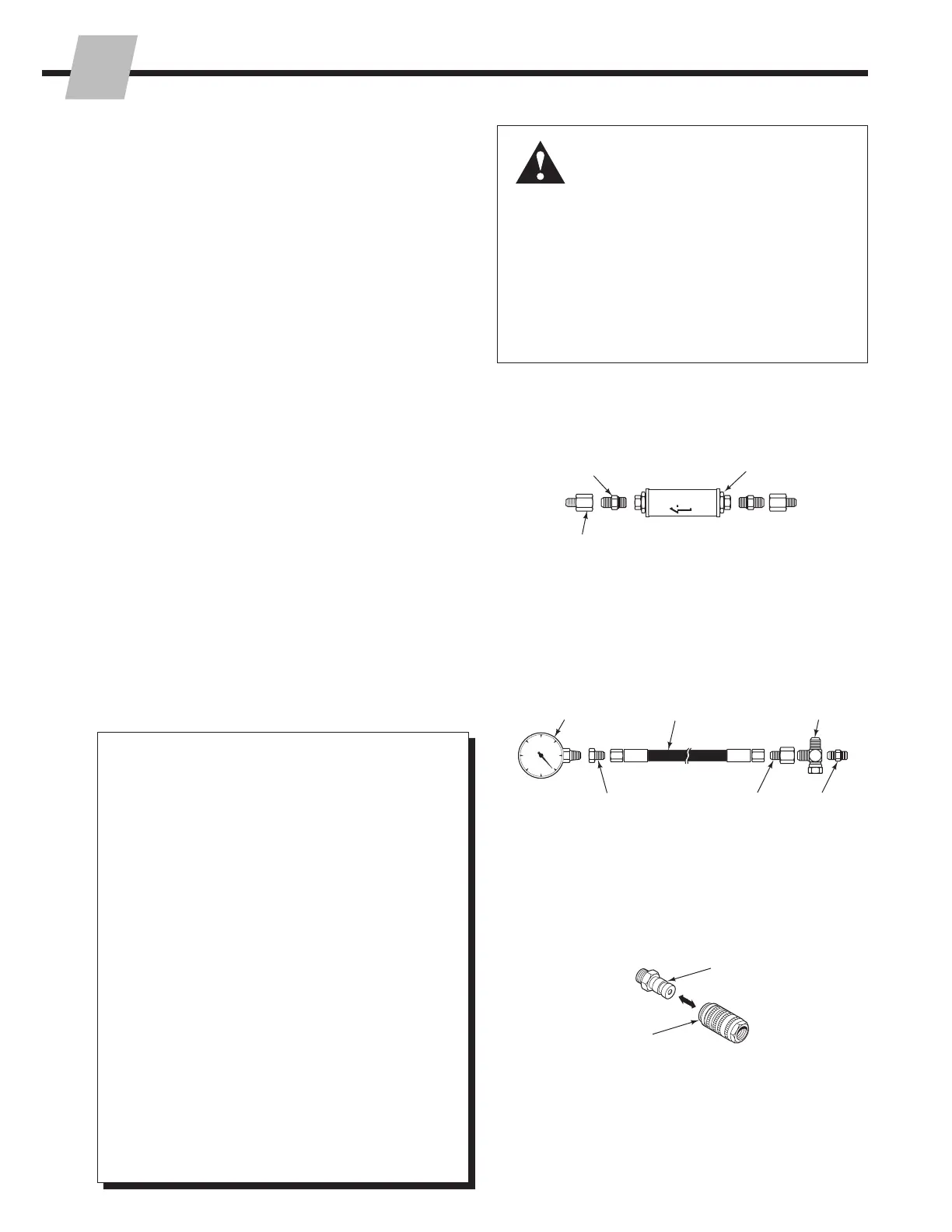

GA0014.eps

AC0127.eps

Flow Meter Kits: 671476 & 671477

Pressure Gauge Kit: 671212

Quick-Disconnect Couplers

(2)No.8-12JIC/O-Ring

FlowMeter

(2)No.6-8JIC

Reducer

Pressure

Gauge*

No.6-6Hose*

No.6and

No.8JIC

SwivelTee

No.4-6Pip/JIC*

No.6-8JIC

Reducer

No.4,No.6*

andNo.8

JIC/O-Ring

*NOTE: DiagnosticsKit397382

includesitemsmarked.

MaleStraightThread

O-RingCoupler:

No.4(PartNo.212282)*

No.5(PartNo.210378)

No.6(PartNo.678592)

FemaleJICThread

Coupler:

No.4(PartNo.210385)*

No.6(PartNo.678591)

Determine All The Facts –Itisimportantthatall

thefactsregardingtheproblemaregatheredbefore

beginningserviceprocedures.Therststepisto

talktotheequipmentoperator.Askforacomplete

descriptionofthemalfunction.Thefollowing

guidelinescanthenbeusedasastartingpointto

begintroubleshootingprocedures:

Clamp Circuit

• Attachmentdropsloadafterithasbeenpickedup.

• Attachmentwillnotcarryloadtoitsratedcapacity.

• Attachmentarmshaveuneventravel.

• Attachmentarmstravelslowly.

• Attachmentarmswillnotmove.

Tocorrectoneoftheseproblems,seeSection4.4-1

and4.4-2.

Sideshift Circuit

• Attachmentdropsloadwhilesideshifting.

• Attachmentdropsloadatendofsideshiftstroke.

• Attachmentsideshiftsleftandrightatdifferent

speeds.

• Attachmentwillnotsideshift.

• Attachmentarmswillnotmove.

Tocorrectoneoftheseproblems,seeSection4.4-2,

4.4-3and4.4-4.

Loading...

Loading...