208743 Rev. 1

ERIODIC MAINTENANCE

P

9

100 Hour

Maintenance

Every time the lift truck is serviced or every 100 hours

of truck operation, whichever comes first, complete the

following maintenance procedures.

❏ Check for loose or missing bolts, worn or damaged

hoses and hydraulic leaks.

❏ Inspect the clearance between the truck lower carriage

bar and the fork positioner lower hooks. Tighten the

lower hook bolts to a torque of 115-125 ft.-lbs.

(155-170 Nm).

❏ Lubricate the grease fittings (sideshift to access) and

lower bearings with chassis grease.

❏ Lubricate the shaded areas (refer to step 12 of

Installation) on the fork bars with Slip Plate (Slix It) No.

8035 lubricant - Cascade part no. 599489.

500 Hour

Maintenance

After each 500 hours of truck operation, in addition to the

100 hour maintenance, perform the following procedures.

❏ Tighten the backrest capscrews to a torque of 115-125

ft.-lbs. (155-170 Nm).

❏ Check the forks and carriage for wear with wear gauge

part no. 209509 (Class II) or 209507 (Class III). Refer to

Installation step 13.

❏ Apply chassis grease to the upper bearing zerk fittings

and fork carrier bearings.

1000 Hour

Maintenance

After each 1000 hours of truck operation, in addition to

the 100 and 500 hour maintenance, perform the following

procedures.

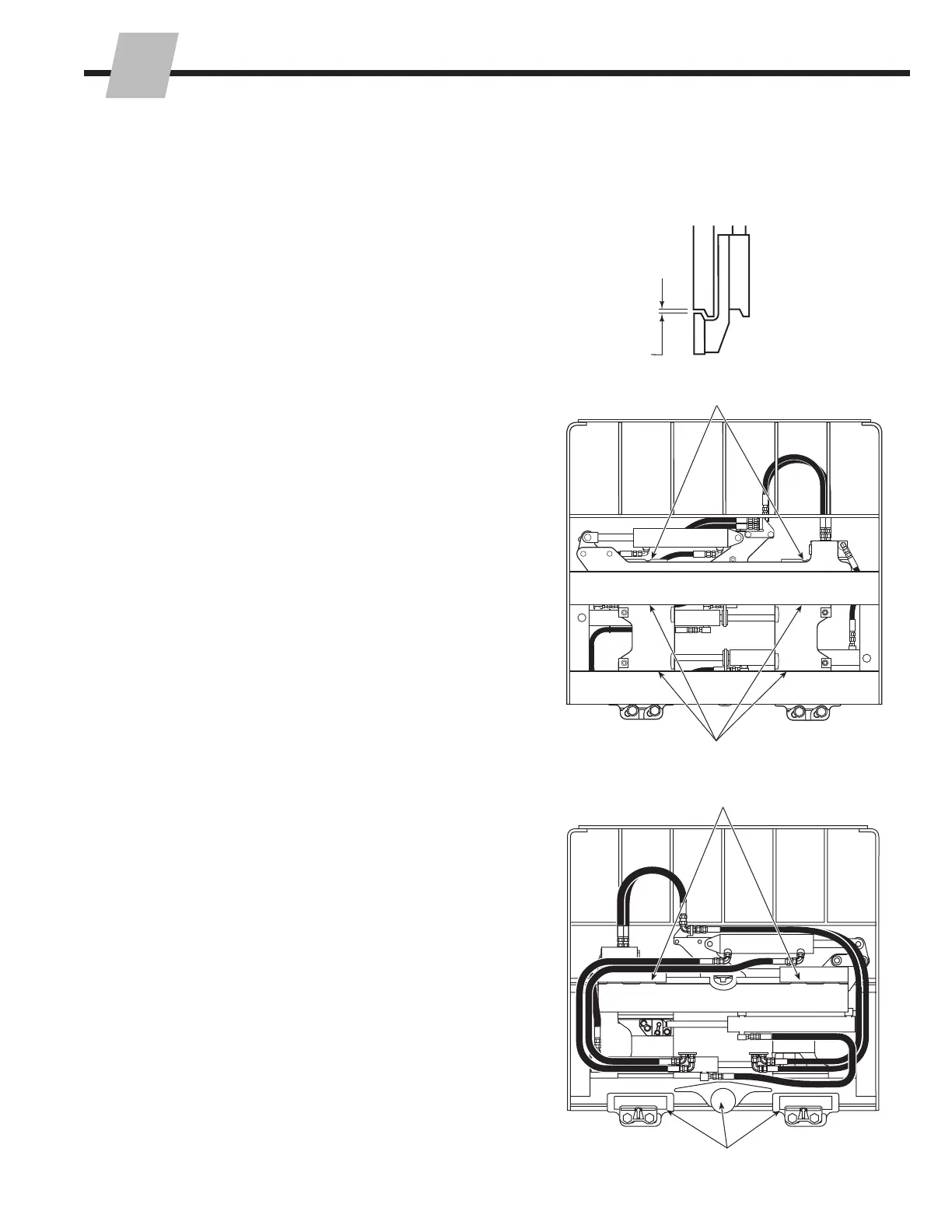

❏ Inspect the thickness of the upper bearings. If either

of the bearings are worn to less than 1/16 in. (1.5 mm)

thick, they should be replaced.

❏ Inspect the exposed thickness of the lower bearings. If

the exposed thickness is less than 1/16 in. (1.5 mm),

they should be replaced.

❏ Inspect the fork carrier bearings. If the exposed

thickness is less than 1/16 in. (1.5 mm), they should be

replaced.

2000 Hour

Maintenance

After each 2000 hours of truck operation, in addition to

the 100, 500 and 1000 hour maintenance, perform the

following procedures.

❏ Replace the upper and lower bearing sets and fork

carrier bearings.

IMPORTANT: After completing any service

procedure, always test each function through 5

complete cycles. First test the attachment empty,

then test with a load to make sure the attachment

operates correctly before returning it to the job.

.09 in.

(2.3 mm)

FP0091.eps

Upper Bearing

Zerk Fittings

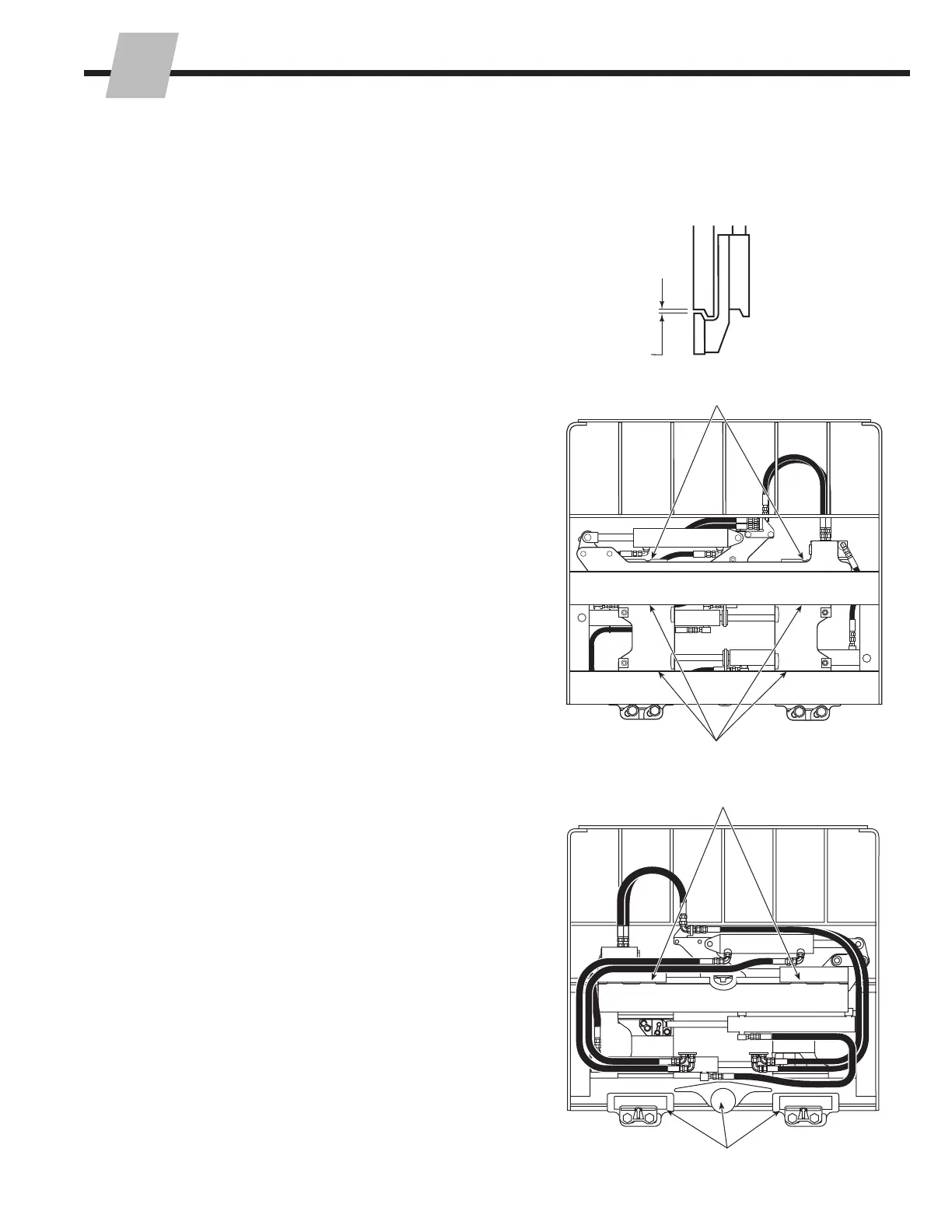

Fork Carrier

Bearings

FP0092.eps

Upper Bearings

Lower Bearings

Lower Hooks

Clearance

Loading...

Loading...