6871082-R2 15

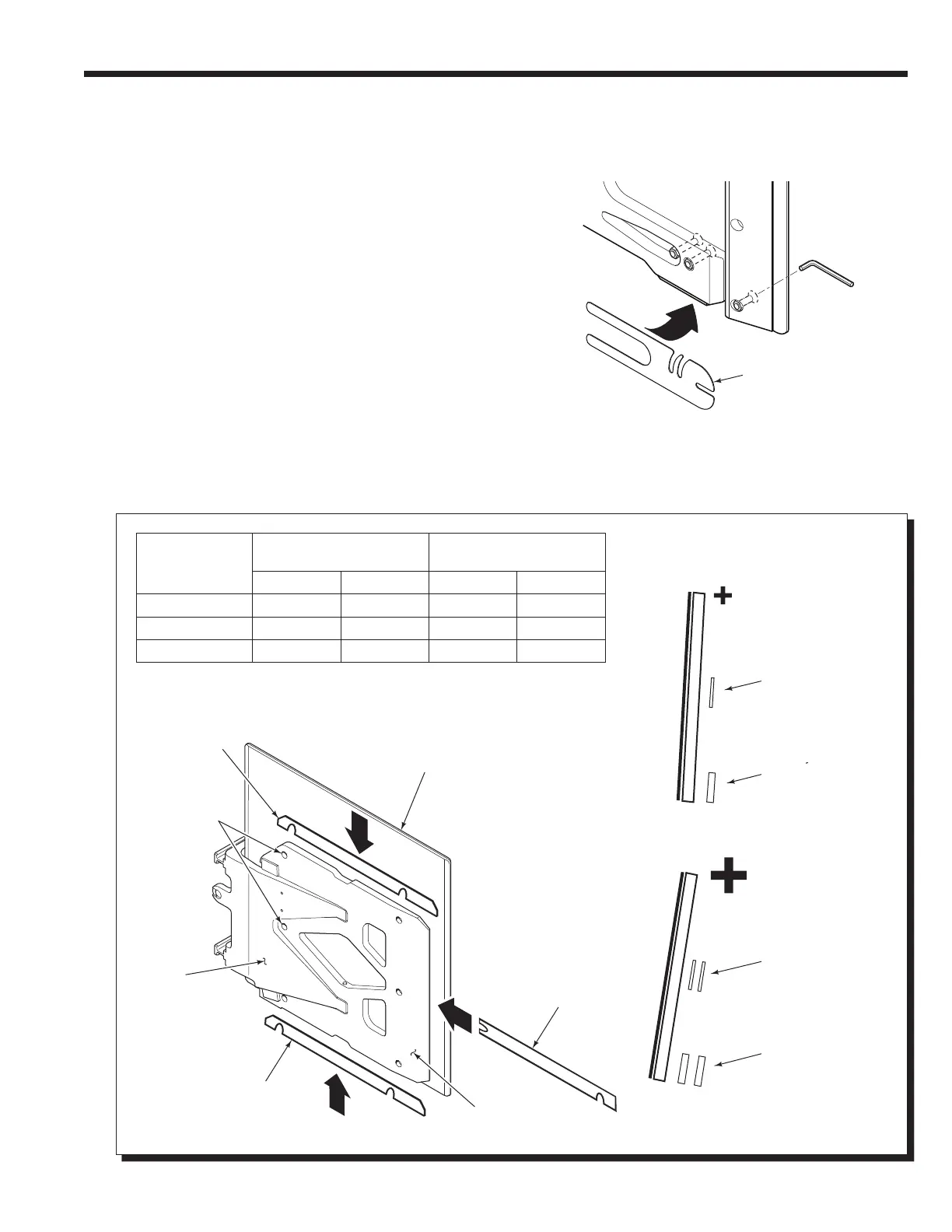

ADJUSTING PAD CAMBER

STANDARD (SHIMMED) DESIGN

CC0012.eps

4 Loosen the contact pad capscrews and nuts.

NOTE: It is not necessary to remove the capscrews

and nuts to insert the shims.

5 Install shims as required.

• Positive Camber – Install shims at the bottom and

middle of the pad to increase clamp force at the

bottom of the load.

NOTE: This will increase the clamp force

percentages on the lower spindles readout of the

4-Point Force Distribution Tester.

• Negative Camber – Install shims at the top and

middle of the pad to decrease clamp force at the

bottom of the load.

NOTE: This will increase the clamp force

percentages on the upper spindles readout of the

4-Point Force Distribution Tester.

CAUTION: Use an equal number of shims on each

contact pad. Pad camber must be the same on both

sides of the attachment for proper load handling.

"U" Shim

4

4

5

5

5

5

Top Shim

Contact Pad

Pad

Capscrews

and Nuts

Arm

Bottom Shim

Stabilizer

Middle Shim

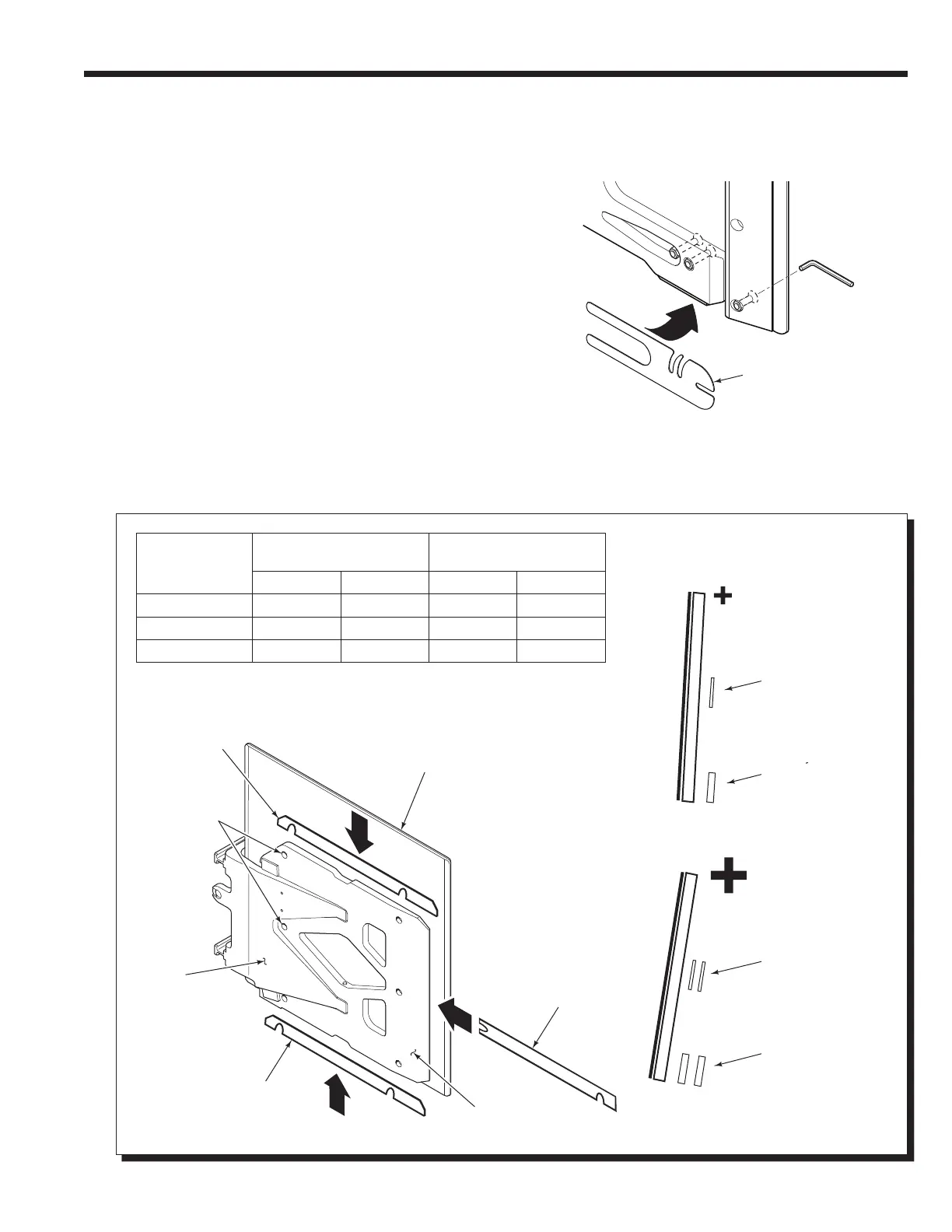

FOR MINIMUM

POSITIVE CAMBER:

FOR MAXIMUM

POSITIVE CAMBER:

Middle Shim:

Long Shim – One Each

0.06 in. (1.6 mm)

"U" Shim –

One Each, 2 Places

0.04 in. (1 mm)

Middle Shim:

Long Shim – Two Each

0.06 in. (1.6 mm)

"U" Shim –

Two Each, 2 Places

0.04 in. (1 mm)

Bottom Shim:

Long Shim – One Each

0.125 in. (3.2 mm)

"U" Shim –

One Each, 2 Places

0.08 in. (2 mm)

Bottom Shim:

Long Shim – Two Each

0.125 in. (3.2 mm)

"U" Shim –

Two Each, 2 Places

0.08 in. (2 mm)

Contact Pad

Camber

Clamp Force Change @

Maximum Shimming ◆

Clamp Force

Distribution

Upper Lower Upper Lower

Neutral ▲

— — 35% 65%

Negative +10% –10% 45% 55%

Positive –10% +10% 25% 75%

▲ Shimmed equally in all locations.

◆ Camber based on 12 mm total shims negative or positive position.

Loading...

Loading...