6871082-R216

ADJUSTING PAD CAMBER

FLEXIBLE (ADJUSTA-BLOCK) DESIGN

The following procedure is performed on attachments

with flexible (ADJUSTA-BLOCK) design for contact pad

and stabilizer. This procedure can be performed with the

attachment mounted on the truck. A Cascade 4-Point

Force Distribution Tester is required for this procedure.

IMPORTANT: Clamp circuit pressure should be adjusted,

if required, prior to adjusting the pad camber. Refer to

Installation Step 11 (page 7).

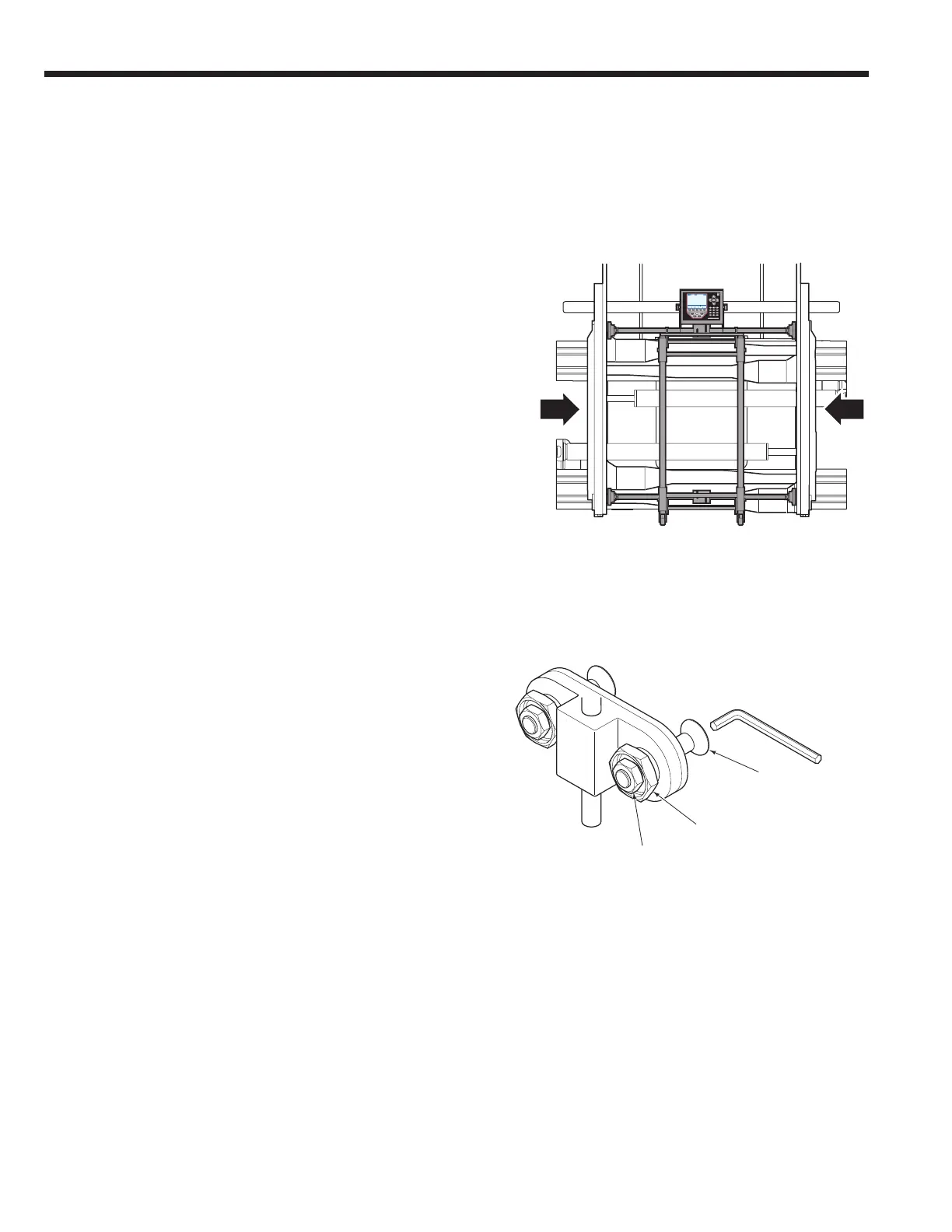

1 Extend the arms to the most common load width.

Lower the contact pads to just above the floor.

2 Position the tester between the contact pads. Adjust

the tester spindle locations to be perpendicular to

the contact pad surfaces and to the desired position

based on the type of product being handled.

3 Clamp on the tester and hold activated for 5 seconds.

4 The tester will display clamp force and percentage of

clamp force for each spindle location and total clamp

force (sum of force of the four spindles).

5 Clamp force distribution should be within the desired

percentages and tolerances.

If the tolerance difference is greater than allowable

tolerance difference, the contact pads require pivot

block adjustment. Continue to Step 6 for adjustment.

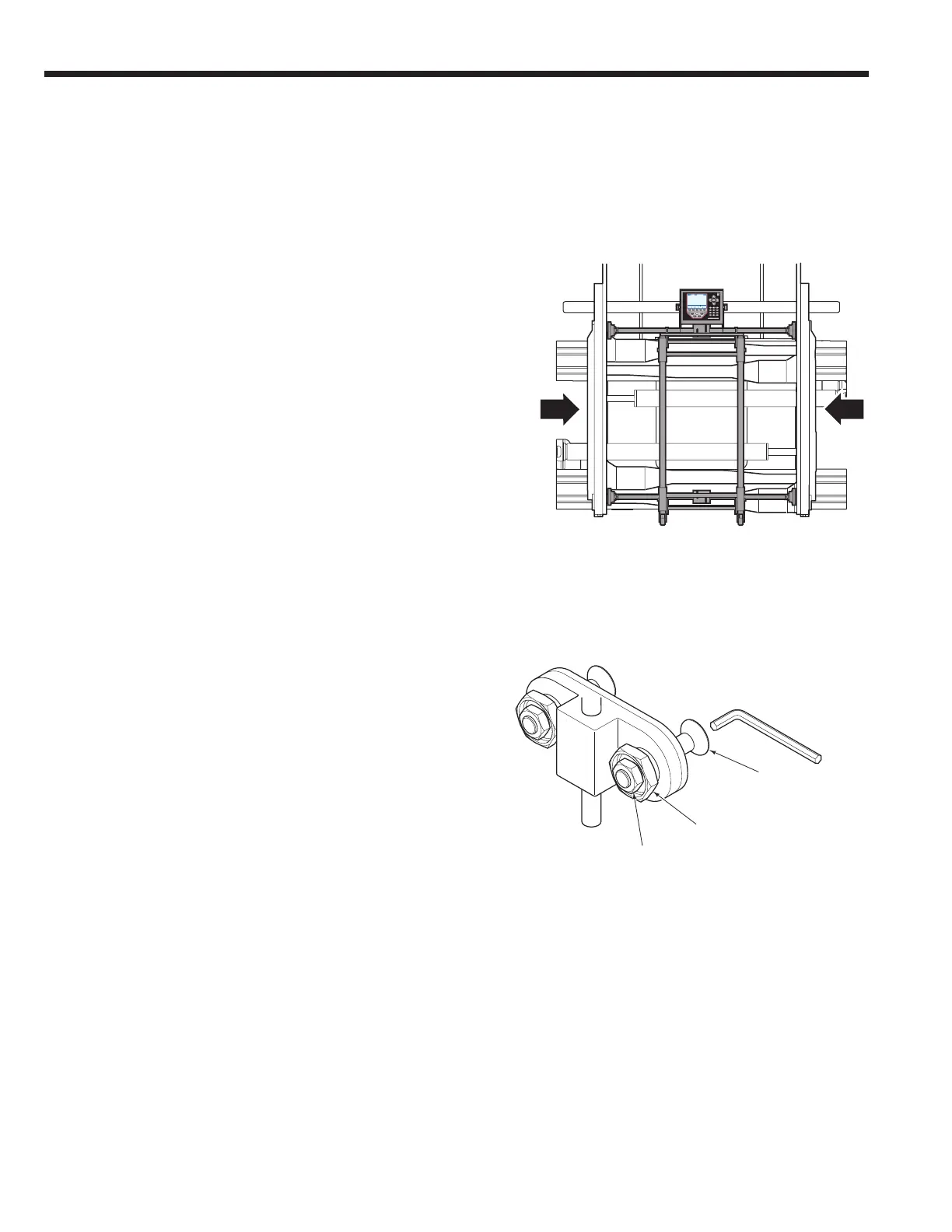

Locking Nut

Capscrew

Collar

8mm

Allen Wrench

ADJUSTA-BLOCK Assembly

6 Clamp force distribution can be changed at the

ADJUSTA-BLOCK locations on the right hand contact

pad. Tune as follows:

• Loosen the locking nuts 3 turns. Use an 0.31 in.

(8 mm) allen wrench to hold the capscrews.

• Adjust the collar using a 1.25 in. (32 mm) socket.

Turn the collar CW to increase clamp force, CCW to

decrease clamp force. One full turn of the collar is

approximately 0.08 in. (2 mm) linear travel or 10% of

force.

Follow adjustment sequence, Step 7.

Procedure continued on the following page.

3

Loading...

Loading...