5 . MAINTENANCE AND ADJUSTMENTS

5.31

Challenger MT500B EU

5

5.20.4 - Headlight adjustment

The headlights are adjusted by tightening or loosening the

three screws as required.

NOTE: Do not let your fingers come into direct contact

with the iodine bulbs.

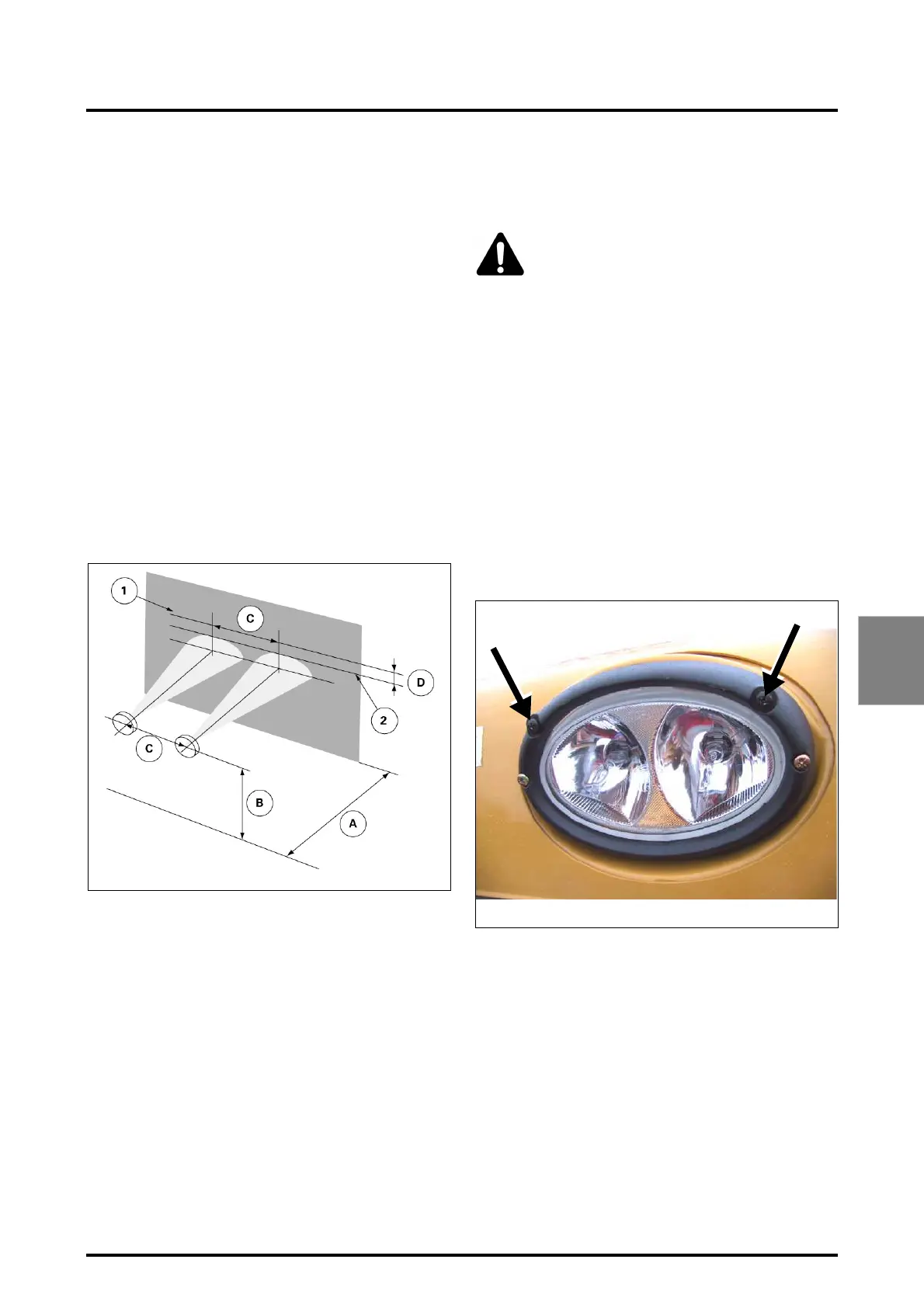

Legend (Fig. 47)

A. Distance between the headlights and a wall or a

screen.

B. Height from the centre of the headlights to the ground.

C. Headlights centre to centre distance.

D. Height after adjustment.

5.20.4.1 - Headlight adjustment procedure

1. Position the tractor facing a wall or a screen 7.5m

away and on a level surface;

2. Draw a horizontal line, 1, on wall equal to height, B;

3. Draw two vertical lines on wall equal to width, C;

4. Draw a horizontal line, 2, according to D = (B x 0.1).

Adjust each headlight individually, by masking the

opposite light, and aligning the upper edge of the

lighted zone with the top of line 2.

5.20.5 - Xenon work headlights (optional)

Certain precautions must be taken when replacing bulbs on

models equipped with this option.

WARNING: The electrical connection

between headlight and light ballast is under

HIGH VOLTAGE and must not be discon-

nected. Before replacing the xenon bulb,

always switch headlights off and disconnect from the

power supply.

Never insert foreign objects or fingers into the bulb

holder.

- The light ballast is to be attached next to the head-

light. Install the headlight and light ballast in a way

that excludes a negative effect on the engine cooling

system.

- Make sure not to twist the power supply cable

between headlight and light ballast by more than 90°

and/or bend it by radius smaller than 20 mm.

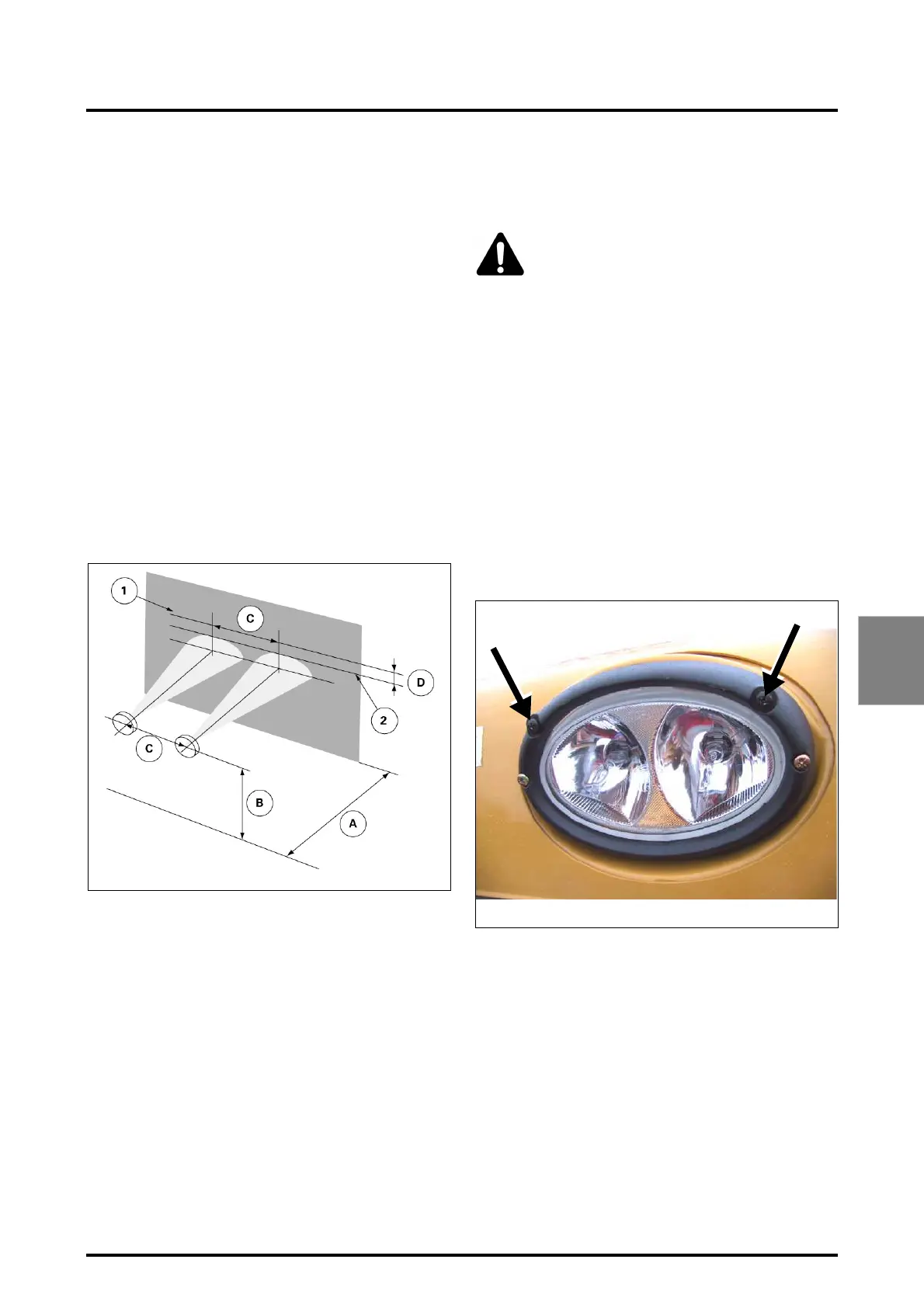

5.20.5.1 - Adjusting work headlights

The work headlights are adjusted by screwing the 2 screws

in or out as required.

Fig. 47

Z2-525-05-03

Fig. 48

CE-002-01-05

Loading...

Loading...