Maintenance Manual 15

PEFS F3 Maintenance Manual, Version 1.2, Feb 2018

© Copyright 2017 Chubb Fire & Security Pty Ltd

e. Manifold block is adequately secured to the equipment.

f. Clamps are adequately secured to the equipment and firmly hold the actuation hose in place.

2. Check electric actuation system (if fitted) is intact and not damaged:

a. Electrical cabling is not worn, split, cut or kinked.

b. Electrical cabling has protective sleeves fitted along locations where rubbing can occur.

c. Electrical connectors are intact and not damaged.

d. Separate connectors and check to ensure they are free from ingress of dirt, water and corrosion.

Replace if required. Re-connect all electrical connectors.

e. All cabling clamps and supports are adequately secured to the equipment and firmly holds the cabling

in place.

Manual Actuators (Item 5)

WARNING: The cylinder and actuation pipework contains high pressure. Do not remove any parts from

the cylinder or actuation pipework unless it is depressurised first.

Note: The LOP Manual actuators are designed to “fail to safe”. That is any fault causing leakage will activate the

system. As such the LOP Manual actuators may be considered operational if the below listed checks are carried

out.

1. Check that all actuators are intact and not damaged.

2. Check that all actuators are accessible and access has not been restricted by equipment modification.

3. Check that all pull pins and security ties (anti tamper seals) are in place and secure. Replace security ties if

missing or broken.

4. Check that the pull pin retainer wire is correctly securing the pull pin to the actuator.

5. Check to ensure pressure is reading in the green sector of the pressure indicator

6. Remove the front housing cover and check that all actuators are:

a. Clean and undamaged.

b. Foil is intact on outlet port nozzle. Replace if required.

c. Schrader Valve has cap fitted to protect against ingress of dust and dirt.

7. Check that all actuators are adequately secured to the equipment.

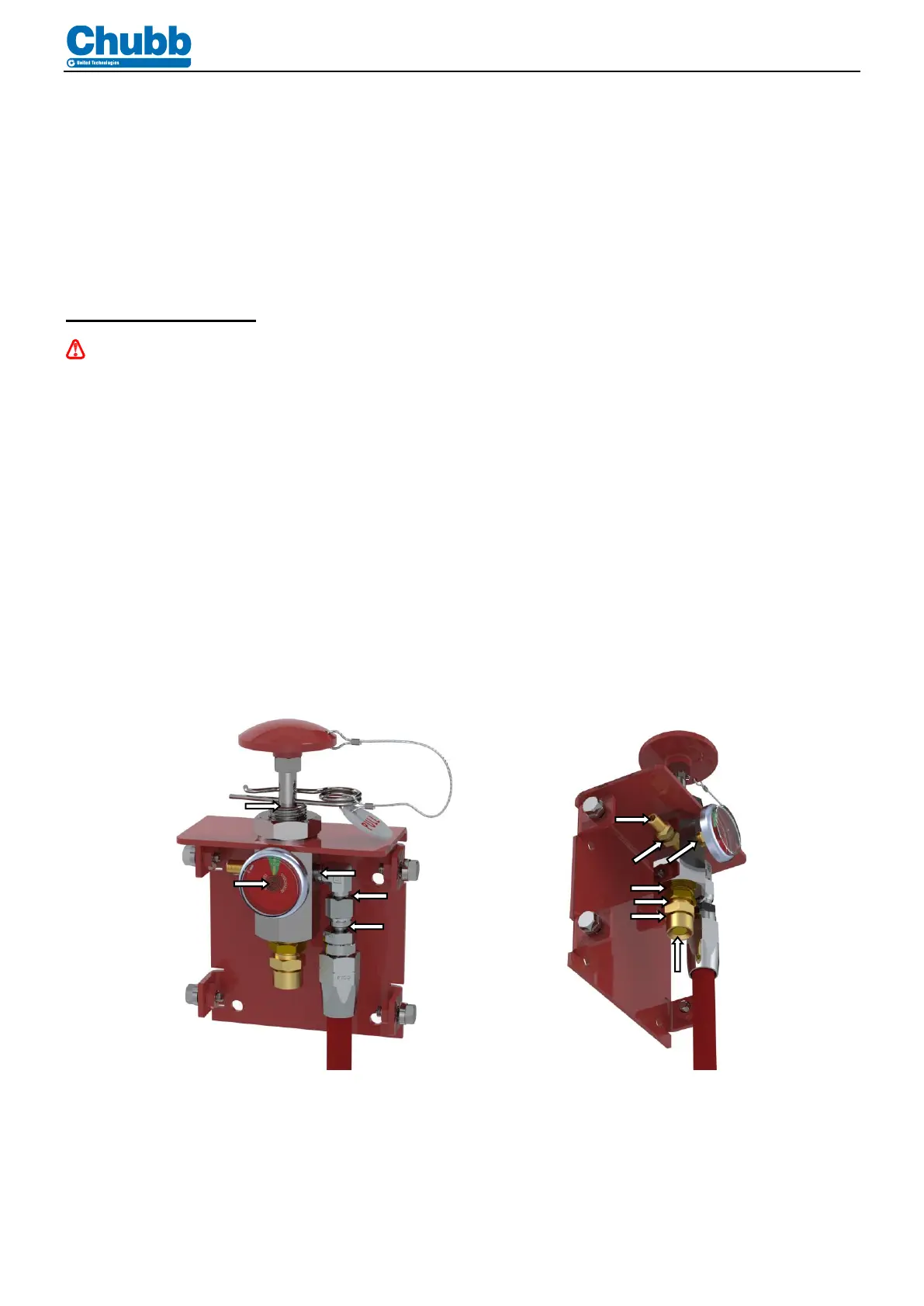

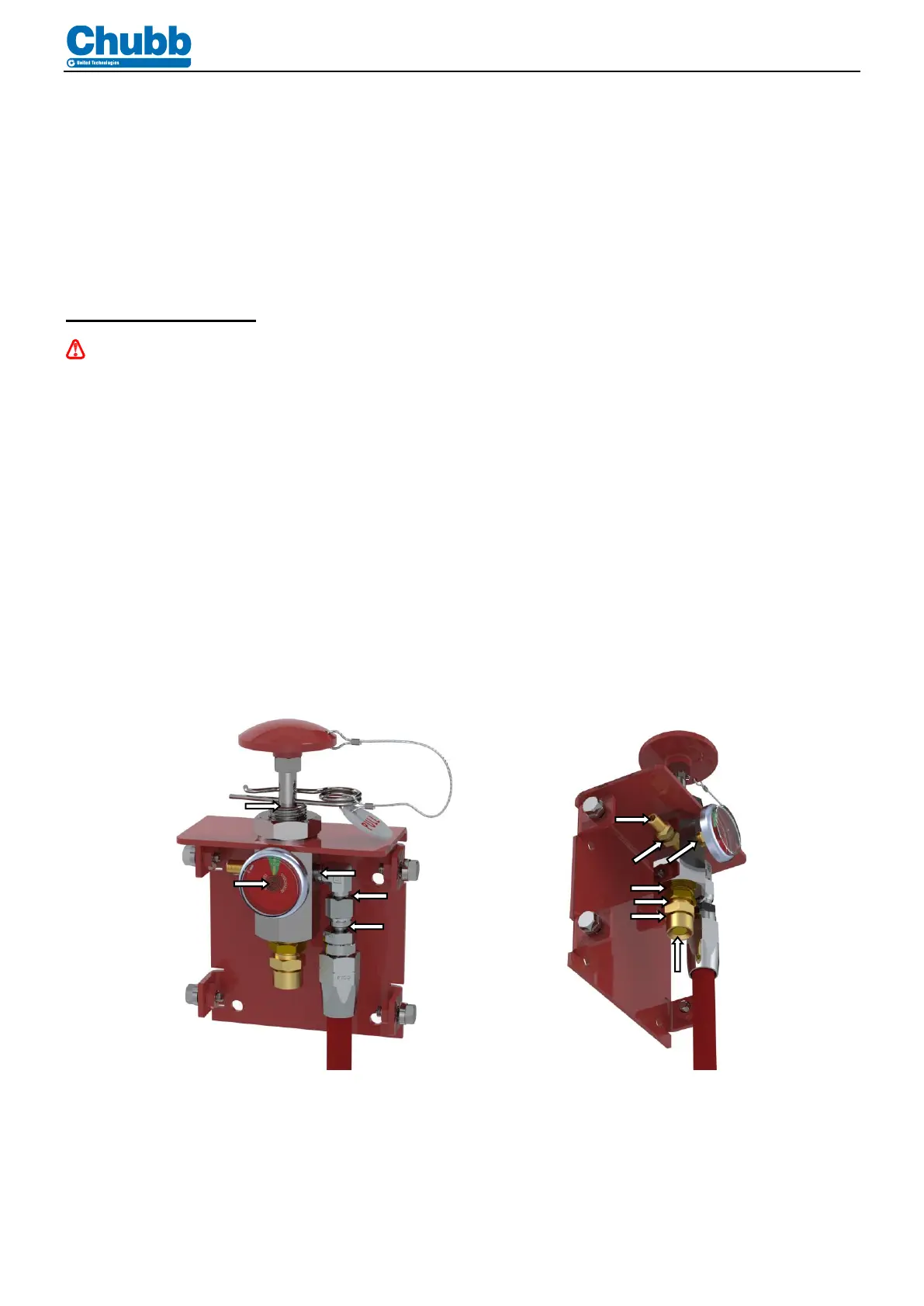

8. Leak Test all connection points (refer figure below) with a liquid leak detection solution. If actuator shows any

signs of leakage, carry out service on actuator.

Figure 1

9. Re-fit housing cover and ensure it is securely bolted on and label is intact and readable.

Loading...

Loading...