OMM-05-0509-page 9

A. Hardware:

All blower and foundation hardware should be checked to make sure it is tight. All set screws or taper-lock bushing

b

olts should be tightened to the torque values shown in Tables 1 and 2 on page 5.

NOTE: If any set screws have become loose, they must be thrown away and replaced. NEVER

use set screws more

than once. Replace with knurled, cup-point set screws with a nylon locking patch.

B. Blower Bearing Lubrication:

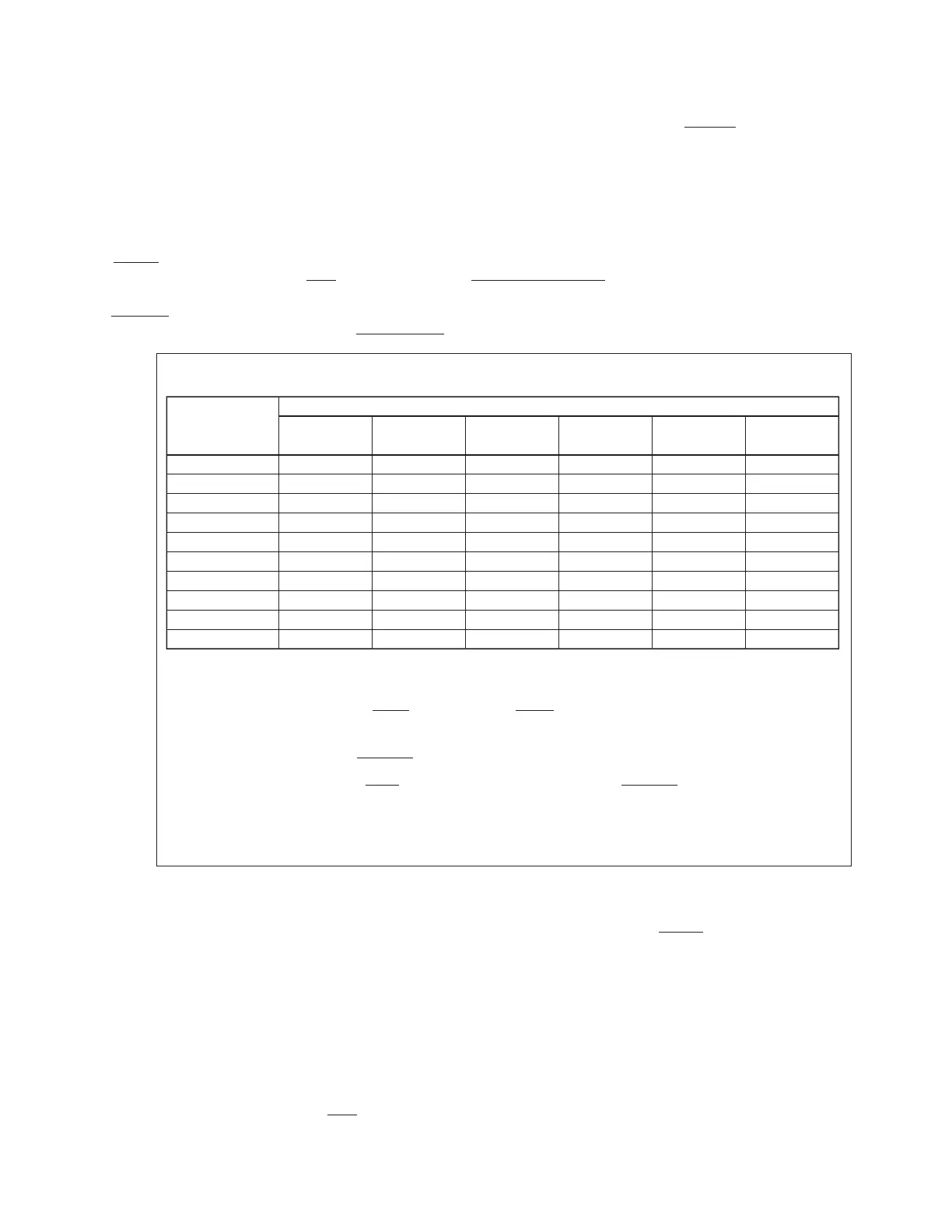

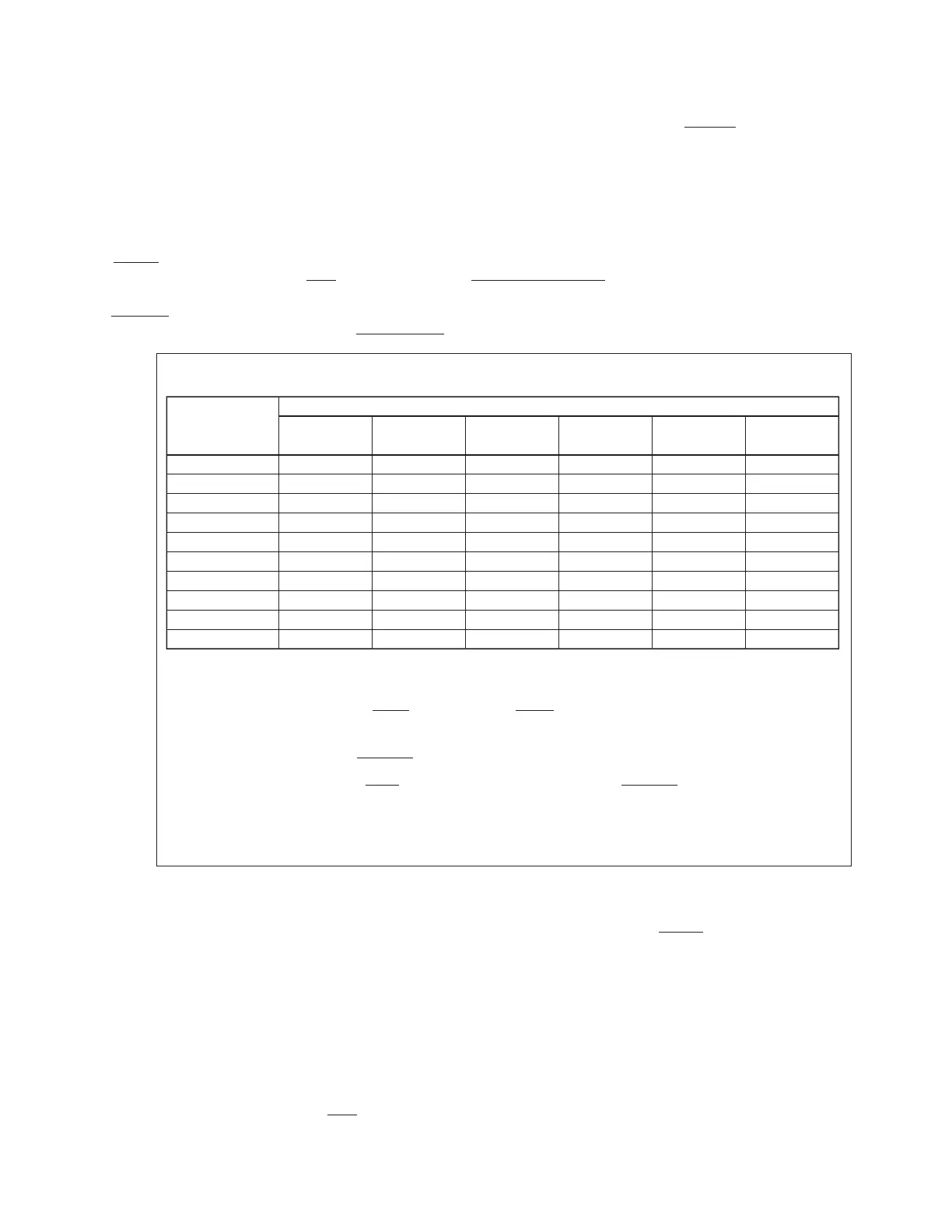

Blower bearings should be re-lubricated per the chart below for all clean and dry applications where the ambient tem-

perature or blower air temperature is -20°F (-29°C) up to 120°F (49°C). If your application is dirty, moisture laden air, or

is outside the temperature limits stated previously, consult the bearing manufacturer for the proper grease type and

lubrication frequency. The chart below is affixed to every belt driven blower base.

NOTE: For high temperature applications that require high temperature grease in the blower bearings, a chart

similar to below will also specify that ONLY Dow Corning DC44 (silicone based) high temperature

grease should be used.

DO NOT over grease the blower bearings. Generally, 1-2 shots should be enough. Use a hand-operated grease gun at

no more than 40 PSI. IF POSSIBLE, CAREFULLY lubricate the blower bearings while the blower is running.

C. Wheel Balance:

All blower wheels are balanced at the factory. It is not uncommon that additional “trim balancing” is required after the

blower is assembled. Trim balancing of the blower assembly, in the field, is typically always necessary for all replace-

ment wheels. After any wheel is installed, the final balance of the entire blower assembly should be checked.

Refer to Section B on pages 6 and 7 and Fig. 5 on page 8.

Airstream material or chemicals can cause abrasion or corrosion of the blower parts. This wear is generally uneven

and, over time, will lead to the wheel becoming unbalanced causing excessive vibration. When that happens, the wheel

must be rebalanced or replaced. The other airstream components should also be inspected for wear or structural dam-

age and cleaned or replaced if necessary. After cleaning any blower wheel, it should be balanced and then “trim

balanced” on the blower shaft.

There are three ways to balance a blower wheel:

1. Grinding off material for cast aluminum wheels:

If you are grinding on the wheel to remove material, be very careful not to grind too much in one area. That could

affect the structural integrity of the wheel.

FAN

OPERATING

SPEED (RPM)

1

/2” TO

1”

1

1

/8” TO

1

1

/2”

1

5

/8” TO

1

1

5

/1

6

”

2” TO

2

1

/2”

2

11

/16” TO

3

3

/1

6

”

3

7

/16” TO

3

1

5

/1

6

”

FAN SHAFT O.D. IN INCHES

6

6

6

5

5

5

4

3

2

2

UP TO 500

501-1000

1001-1500

1501-2000

2001-2500

2501-3000

3001-3500

3501-4000

4001-4500

4501-5000

6

6

5

5

5

4

3

3

2

1

6

6

5

4

3

2

2

1

1

—

6

5

4

3

2

2

1

—

—

—

5

4

3

2

2

1

—

—

—

—

5

4

2

1

—

—

—

—

—

—

The above lubrication frequencies are based on the fan bearings operating in a clean and dry

environment from -20°F (-29°C) up to 120°F (49°C). For hostile, moisture laden environments

and/or temperatures below -20°F (-29°C) or above 120°F (49°C), consult the bearing

manufacturer for the proper grease type and recommended lubrication frequencies.

If possible, carefully lubricate the bearings while the fan is running.

Add grease until a slight bead appears at the bearing seals. DO NOT over grease.

Generally, 1-2 shots with a hand grease gun that has a maximum pressure rating of 40 PSI.

Warning: Over greasing bearings will cause them to run hot.

The TYPE of grease you use MUST BE compatible with the grease already in the bearings.

THIS FAN IS EQUIPPED WITH BEARINGS PRE-LUBRICATED AND READY FOR USE

Generally Recommended Lubrication Frequency in MONTHS

Loading...

Loading...