PF-F/PFU Series

Product-specic cautions

CAUTION

CAUTION

CAUTION

■

Install a pneumatic lter just before the pneumatic

component in the circuit.

■

When supplying compressed air after connecting

pipes, do not suddenly apply high pressure.

●

The pipe connection could dislocate, causing the pipe

tube to y out, leading to accidents.

■

Air quality

●

Use CKD clean air system components appropriate for

your application.

●

Use compressed air that does not contain oil oxides, tar,

carbon, etc., from the air compressor.

●

Use compressed air that does not contain solid foreign

matter.

●

Install a lter, air dryer, and oil mist lter on the primary

side (upstream side) of the sensor. The sensor's rectier

(mesh) recties the ow in the pipe. It does not lter out

foreign matter, so provide a lter.

Use/maintenance

1. When using the product

2. Maintenance and inspection

■

Do not apply excessive rotational force to the

display.

The display rotates 270 degrees; turn it to your

most convenient position. However, forcing the

display to turn by using excessive force can cause

the stopper to break.

■

Before conducting maintenance, turn the power

OFF, stop the supply of compressed air and make

sure that there is no residual pressure.

●

Observe the conditions to ensure safety.

■

Regularly inspect the product at least once a year

to check that it operates correctly.

■

Do not disassemble or modify, as this may cause

malfunction.

■

When suddenly opening the valve that connects to the sensor, uid

with a ow rate dozens of times greater than the rated ow rate may

ow, and this can cause damage to the platinum thin lm sensor or

rectier and ow out to the secondary side. When opening the valve

that connects to the sensor, open it slowly so that the value in the

monitor display may not exceed the rated ow rate.

■

If a problem occurs during operation, immediately turn

the power OFF, stop use, and contact your dealer.

The display may become warm (approximately

40°C), but this is not an abnormality.

■

After the power supply is turned ON, internal

settings such as hardware check are performed for

10 seconds. During this time, the display/output

cannot operate normally. Particularly, if a switch

output is used in the control of an interlock circuit,

an abnormal stop may occur. Mask the output

during this period.

■

When changing the output set value, turn OFF the

equipment rst in order to prevent unexpected

operation in the control system equipment.

■

If this product is used in an interlock circuit, provide

multiple interlock circuits as a precaution against

failure, and also perform regular inspections to

conrm normal operation.

■

Make sure that no force is applied to the resin parts

when piping.

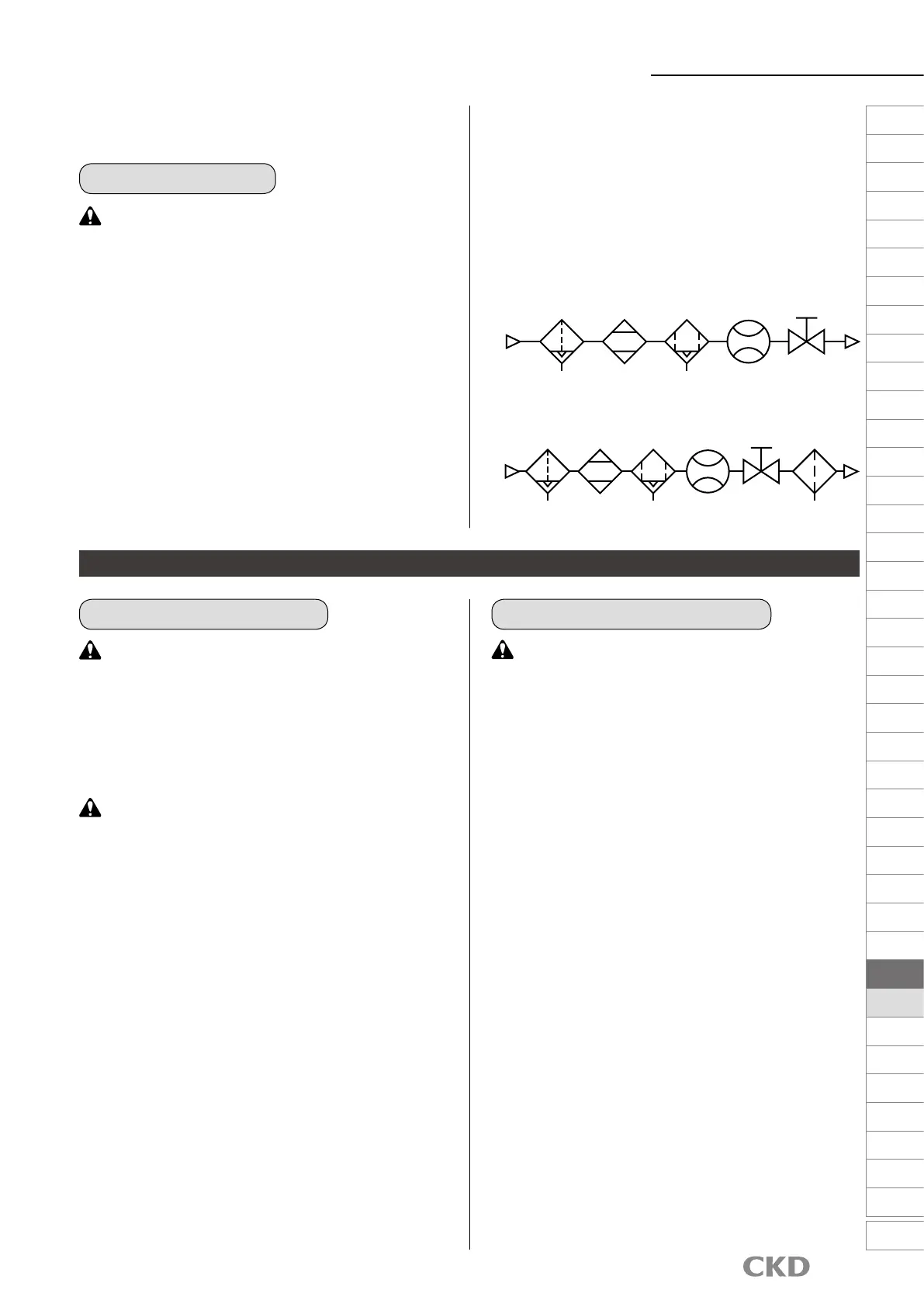

4. Pneumatic source

·When the ultra clean air is required

WARNING

Flow rate

sensor

PFD series

Oil mist

lter

ValveAir dryerFilter

Flow rate

sensor

PFD series

Oil mist

lter

ValveAir dryer Filter for

precise

ltration

Filter

F.R.L

F (Filtr)

R (Reg)

L (Lub)

PresSW

Shutoff

SlowStart

FlmResistFR

Oil-ProhR

MedPresFR

No Cu/

PTFE FRL

Outdrs FR

F.R.L

(Related)

CompFRL

LgFRL

PrecsR

VacF/R

Clean FR

ElecPneuR

AirBoost

SpdContr

Silncr

CheckV/

other

Jnt/tube

AirUnt

PrecsCompn

Mech/

ElecPresSw

ContactSW

AirSens

PresSW

Cool

AirFloSens/

Contr

WaterRtSens

TotAirSys

(Total Air)

TotAirSys

(Gamma)

RefrDry

DesicDry

HiPolymDry

MainFiltr

Dischrg

etc

Ending

1391

Loading...

Loading...