7

ENGLISH

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

Fastening Jointer to Supporting Surface

(Fig. M)

If during operation, there is any tendency for the jointer

to tip over, slide or “walk” on the supporting surface, the

jointer must be secured to the supporting surface. Four

holes (two of which are shown at

22

Fig.M, are provided

for thispurpose.

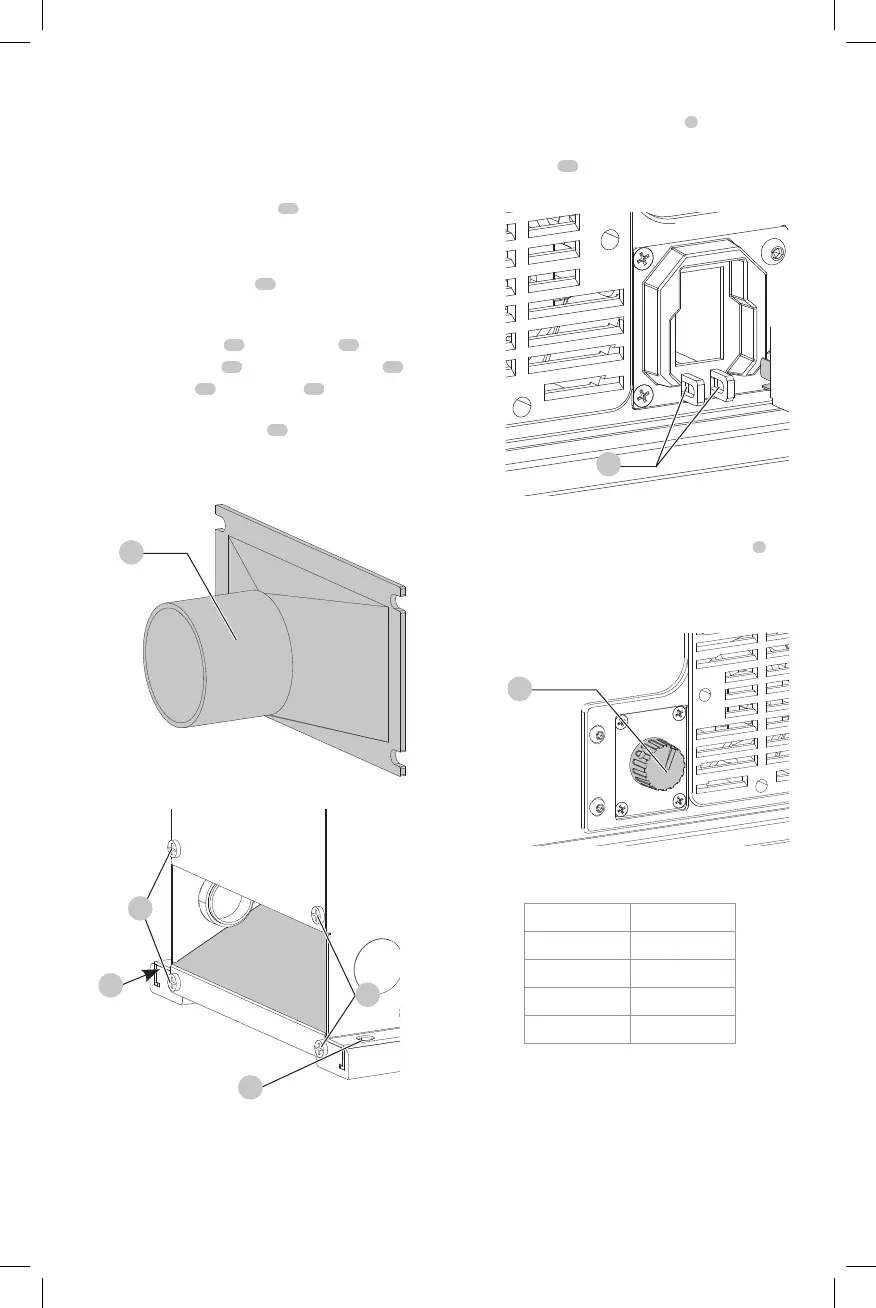

Dust Collector Hose Adapter (Fig. L, M)

A dust collector hose adapter

23

is supplied with the

jointer to help connect it to a standard 2" (51 mm) vacuum

hose. To assemble the adapter:

1. Remove two screws

25

. Loosen screws

26

.

2. Slide adapter’s slots

24

under loosened screws

26

.

3. Tighten screws

26

when adapter

23

is in

properlocation.

4. Replace and tighten screws

25

.

NOTICE: Do not install this vacuum hose adapter

unless you will be using a dust collector.

Fig.L

23

Fig.M

25

26

22

22

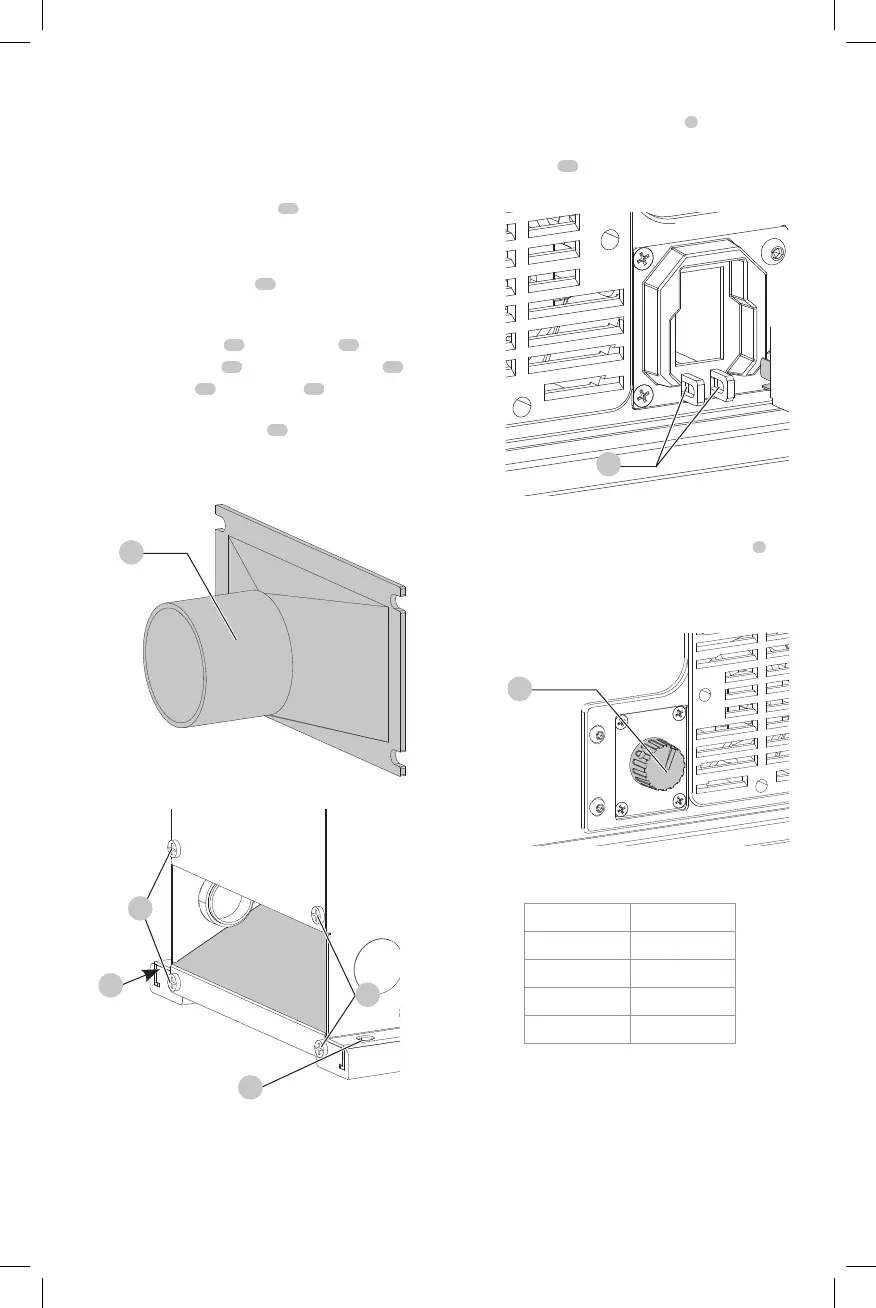

Stopping and Starting the Jointer (Fig. N)

To turn the planer on, lift up the switch

5

. The planer locks

on automatically. To turn the tool off, press the switch

down. Two holes

27

are provided in the bottom of the

switch housing for locking off the planer with apadlock.

Fig.N

27

Variable Speed Control (Fig. O)

Your jointer is supplied with variable speed control

6

that

enables you to operate the machine at cutterhead speeds

between 6000 and 11000 RPM. Speed indicators of 1, 2, 3, 4

and 5 are provided on the speeddial.

Fig.O

6

Speed Approximate

RPM

1 6000

2 7250

3 8800

4 9750

5 11000

Speed Selection Chart

Use the speed selection chart to determine the proper

setting for yourworkpiece.

Loading...

Loading...