5 Piping installation

Installation manual

14

2MXM-A9, 3MXM-A9, 4MXM-A9, 5MXM-A9

R32 Split series

3P600450-9T – 2022.09

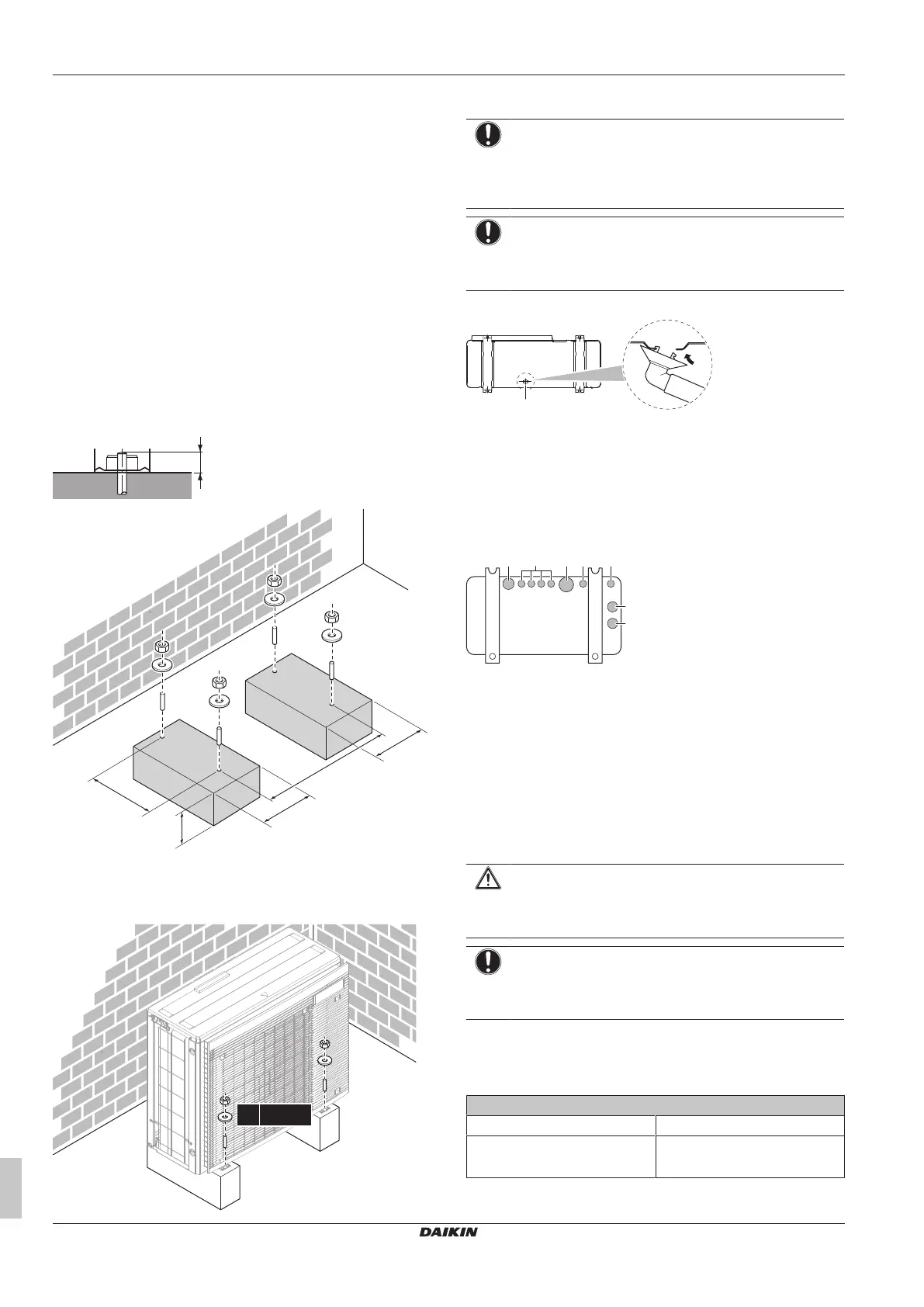

It is recommended to provide at least 150mm of free space below

the unit (300mm for heavy snowfall areas). Additionally, make sure

the unit is positioned at least 100mm above the maximum expected

level of snow. If necessary, construct a pedestal. See "4.2Mounting

the outdoor unit"[414] for more details.

In heavy snowfall areas it is very important to select an installation

site where the snow will NOT affect the unit. If lateral snowfall is

possible, make sure that the heat exchanger coil is NOT affected by

the snow. If necessary, install a snow cover or shed and a pedestal.

4.2 Mounting the outdoor unit

4.2.1 To provide the installation structure

Use a vibration-proof rubber (field supply) in cases where vibrations

may be transmitted to the building.

The unit may be installed directly on a concrete veranda or another

solid surface as long as it provides proper drainage.

Prepare 4 sets of M8 or M10 anchor bolts, nuts and washers (field

supply).

a 100mm above expected level of snow

4.2.2 To install the outdoor unit

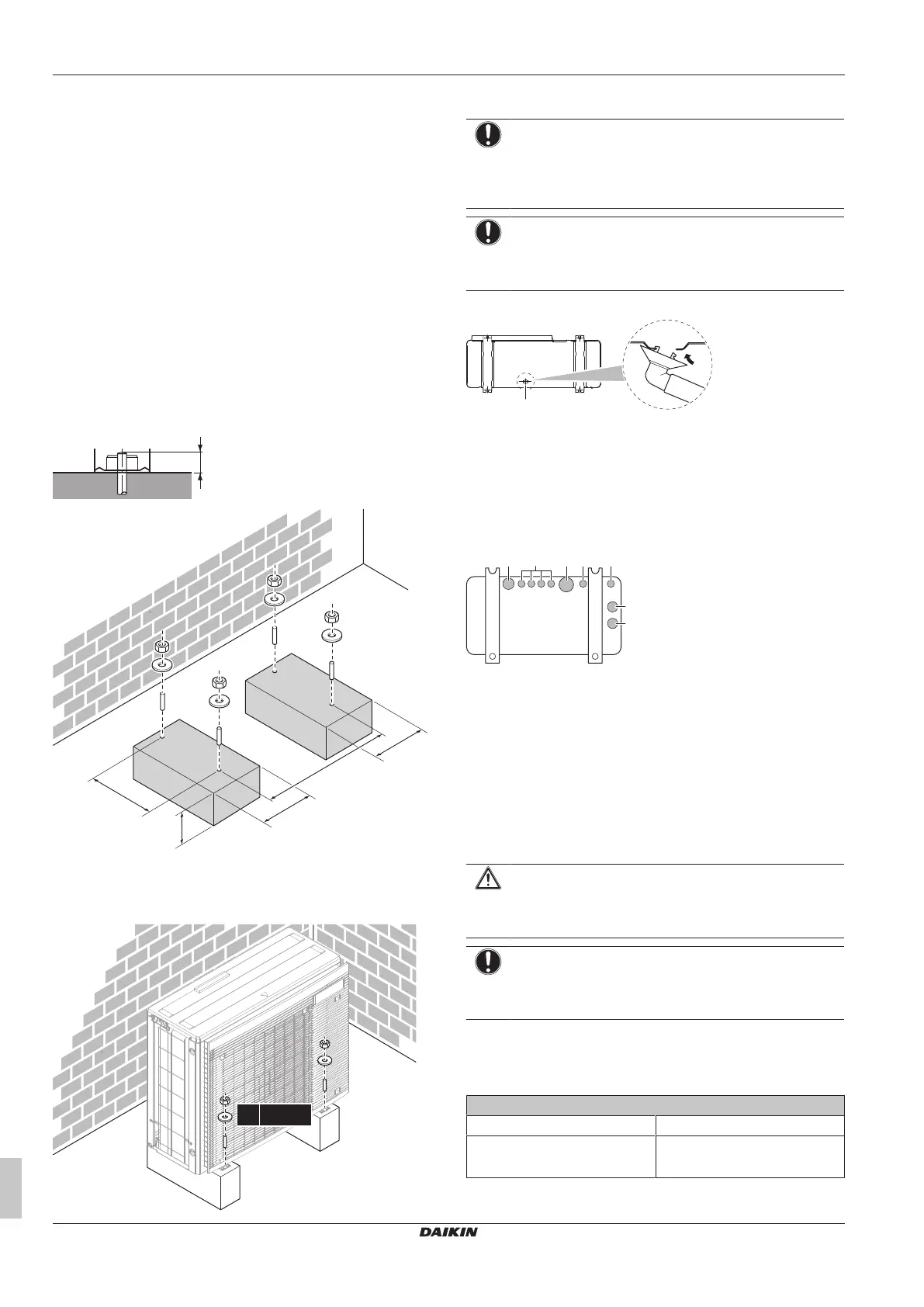

4.2.3 To provide drainage

NOTICE

In cold areas, do NOT use a drain socket, hose and caps

(large, small) with the outdoor unit. Take adequate

measures so that the evacuated condensate CANNOT

freeze.

NOTICE

If the drain holes of the outdoor unit are blocked up by a

mounting base or floor surface, place additional foot bases

≤30mm under the outdoor unit's feet.

▪ Use a drain socket for drainage if necessary.

a Drain hole

To close the drain holes and attach the drain

socket

1 Install drain caps (accessory f) and (accessory g). Make sure

the edges of the drain caps close off the holes completely.

2 Install the drain socket.

a Drain hole. Install a drain cap (large).

b Drain hole. Install a drain cap (small).

c Drain hole for drain socket

5 Piping installation

5.1 Preparing refrigerant piping

5.1.1 Refrigerant piping requirements

CAUTION

Piping and joints of a split system shall be made with

permanent joints when inside an occupied space except

joints directly connecting the piping to the indoor units.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant piping.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

Refrigerant piping diameter

2MXM68

Liquid piping 2× Ø6.4mm (1/4")

Gas piping 1× Ø9.5mm (3/8")

1× Ø12.7mm (1/2")

Loading...

Loading...