50

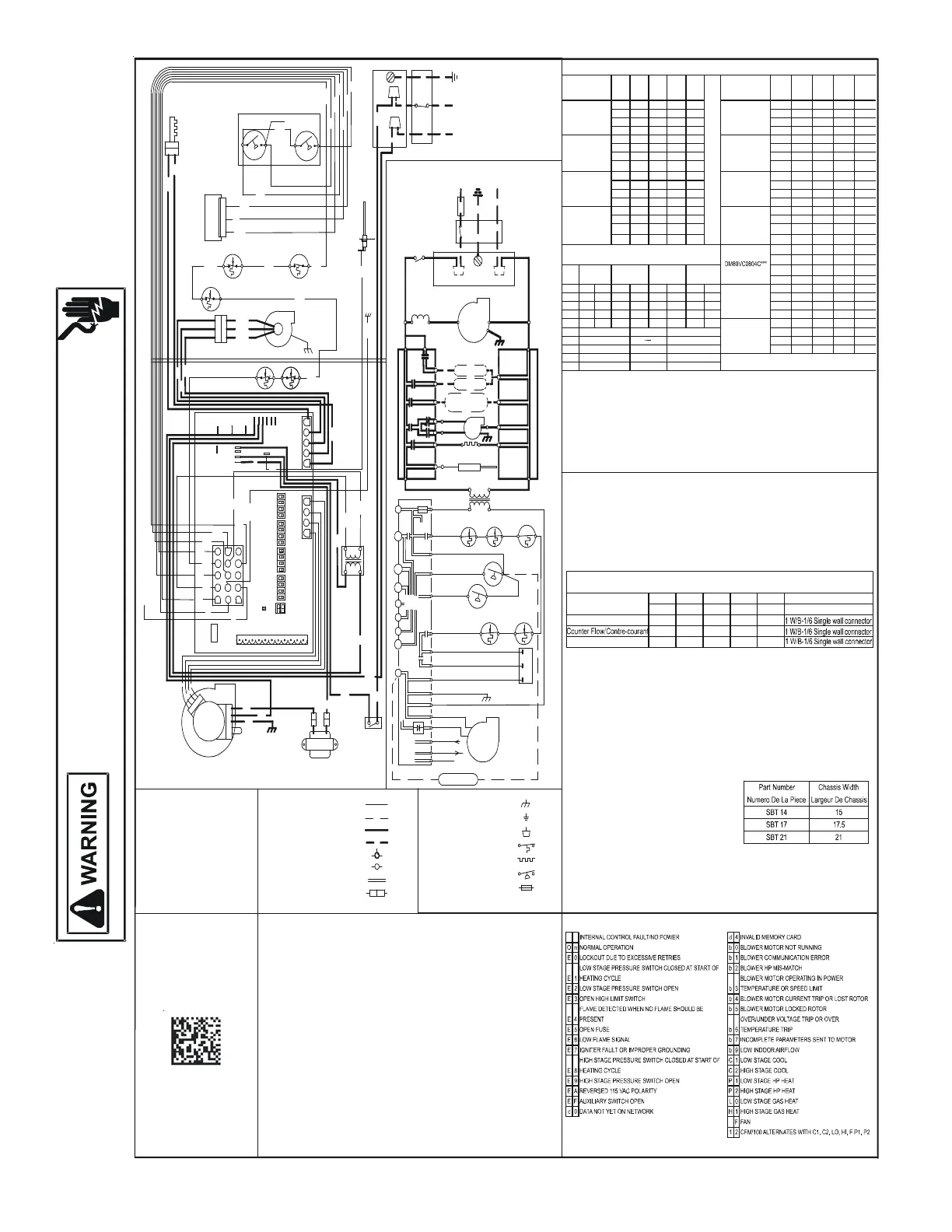

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

HIGH VOLTAGE!

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

OR

INSTALLING

THIS

UNIT

.

M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

.

TO +VDC

TO

MICRO

TO

R

GND (4)

+ VDC (1)

RX (2)

TX (3)

CIRCULATOR

INDOOR

AIR

BLWR

RD

GY

BL

BK

PROPERLY POLARIZED

HUMIDIFIER

GND

PROTECTION DEVICE

BURNER COMPARTMENT

POWER SUPPLY WITH

LINE

RD

TO

C

BK

RD

DISCONNECT POWER

IGNITER

FLAME SENSOR

INTEGRATED CONTROL MODULE

POWER BEFORE

BR

YL

TERMINAL

HI

BL

MVH (14)

PM

ECM MTR

HARNESS

NO

24 VAC

HI VOLTAGE FIELD

AUTO RES ET PRIMARY

LIMIT CONTROL

BEFORE SERVICING.

PS1 (2)

3

CIRCULATOR

BK

BK

OVERCURRENT

24V HUM.

IGNITER

115 VAC/1 /60 HZ

Ø

BLOWER COMPARTMENT

24

BK

PM

BK

INDUCED

DRAFT

BLOWER

HUM-OUT

C

3

115 VAC

INDUCTOR COIL

(ON SOME MODELS)

WH

YL

GND

TO 115VAC/ 1 /60 HZ POWER SUPPLY WITHØ

DEHU M

INTEGRATED CONTROL MODULE

GND

24V HUM.

2

WH

HOT

SURFACE

IGNITER

MVC (8)

NEUTRAL

DOOR

LOW FIRE PRESS.

SWITCH

4

3

2

CHASSIS GROUND

WH

VAC

LOW VOLTAGE (24V)

2 CIRCUIT

CONNECTOR

HUM

HI VOLTAGE (115V)

OVERCURRENT

PSO ( 7)

C

AIR CLEANER

TWO STAGE

GAS VALVE

(WHITE RODGERS)

DISCONNECT

HIGH FIRE

PRESS. SWTICH

INDOOR

HUMIDIFIER

N

BK

MANUAL RESET ROLLOUT

LIMIT CONTROLS

IND LO

40 VA

AUTO RESET AUXILIARY LIMIT

CONTROLS (TWO ON SOME MODELS)

YL

JUNCTION

BLWR

CIRCULATOR

BLOWER

R

1

GND

JUNCTION BOX

SWITCH (TEMP.)

NEUTRAL

BLOWER

COMPARTMENT

DOOR SWITCH

(OPEN WHEN

DOOR OPEN)

C

LINE

BK

4

NEUTRAL

POLARIZED AND

C

FS

2

PLUG CONNECTION

DISCONNECT

PU

RD

INTEGRATED CONTROL

PROT. DEVICE

HIGH FIRE

PRESSURE SWITCH

W1

INTERNAL TO

NO

EQUIPMENT GND

MVL (13)

O

SERVICING. WIRING

WH

YL

ID BLOWER TWO-STAGE PRESSURE

SWITCH ASSEMBLY

5

GND (5)

BK

IND HI

IGN

PK

HLO (10)

(ON SOME MODELS)

PU

L

AIR

WH

MANUAL RESET ROLLOUT LIMIT

CONTROLS

Y1

ELECTRONIC

Y2

RD

NEUTRAL

1

HLI (1)

WH

SWITCH

AUTO RESET PRIMARY

LIMIT CONTROL

NO

WH

TRANSFORMER

MUST BE PROPERLY

BL

OR

OVERCURRENT PROTECTION DEVICE

GN

2

GROUNDED.

LOW VOLTAGE FIELD

W2

WARNING:

FIELD GND

FIELD SPLICE

SWITCH (PRESS.)

11 5

NEUTRAL

BLWR

JUNCTION BOX

GND

1

AND GROUNDED.

BK

GAS

VAL VE

24V THERMOSTAT CONNECTIONS

PU

INDUCTOR COIL

TH (4)

C

HI

1

24V H UM .

TO UNIT MUST BE

VAC

G

C

TR (11)

GR

HOT SURFACE

FLAME

SENSOR

PS2 (12)

LOW FIRE

PRESSURE

SWITCH

1

INTEGRATED CONTROL MODULE

L

YL

3

WIRING TO UNIT

NO

NEUTRAL

N

BR

WH

40 VA

TRANSFORMER

ID

TO

MICRO

WARNING: DISCONNECT

PU

AUTO RESET

AUXILIARY LIMIT

CONTROL (TWO ON

SOME MODELS )

FUSE 3 A

2

HEAT OFF DLY

24 V

3 A

BL

G

12

2

TRIM ENABLE

4

5 CIRCUIT CONNECTOR

4 CIRCUIT MOTOR

CONNECTOR

DIP SWITCHES

4

1

FUSE

15

6

TRIM %

5

HEAT AF

LINE

2

RD

DEHUM ENABLE

2

9

14

Y2

3

HUM

1

YL

NEU TRAL

11

EAC

TWO-STAGE

IN TE GRAT ED

CONTROL

MODULE

8

WH

24 V T HERMOSTAT CONNEC TION S

W1

RD

R

BL

2

Y1

13

1

3

T-STAT

5

BR

BK

COOL PRFL

7

1

C

W2

3

FS

4

YL

YL

DIAGNOSTIC

LED'S

RD

O

DEHUM

10

OR

SEE

NOTE 5

COOL AF

GN

RD

BL

BK

HUM-

IN

HUM-

OUT

CONT FAN

HUM-IN

HUMIDIFIER

EAC

AUX

PU

SEE NOTE 6

COLOR

CODES:

PU

PURPLE

OR

ORANGE

YL YELLOW

BK BLACK

GR GREEN

BR BROWN

PK

PINK

RD RED

GY GRAY

BL

BLUE

WH

WHITE

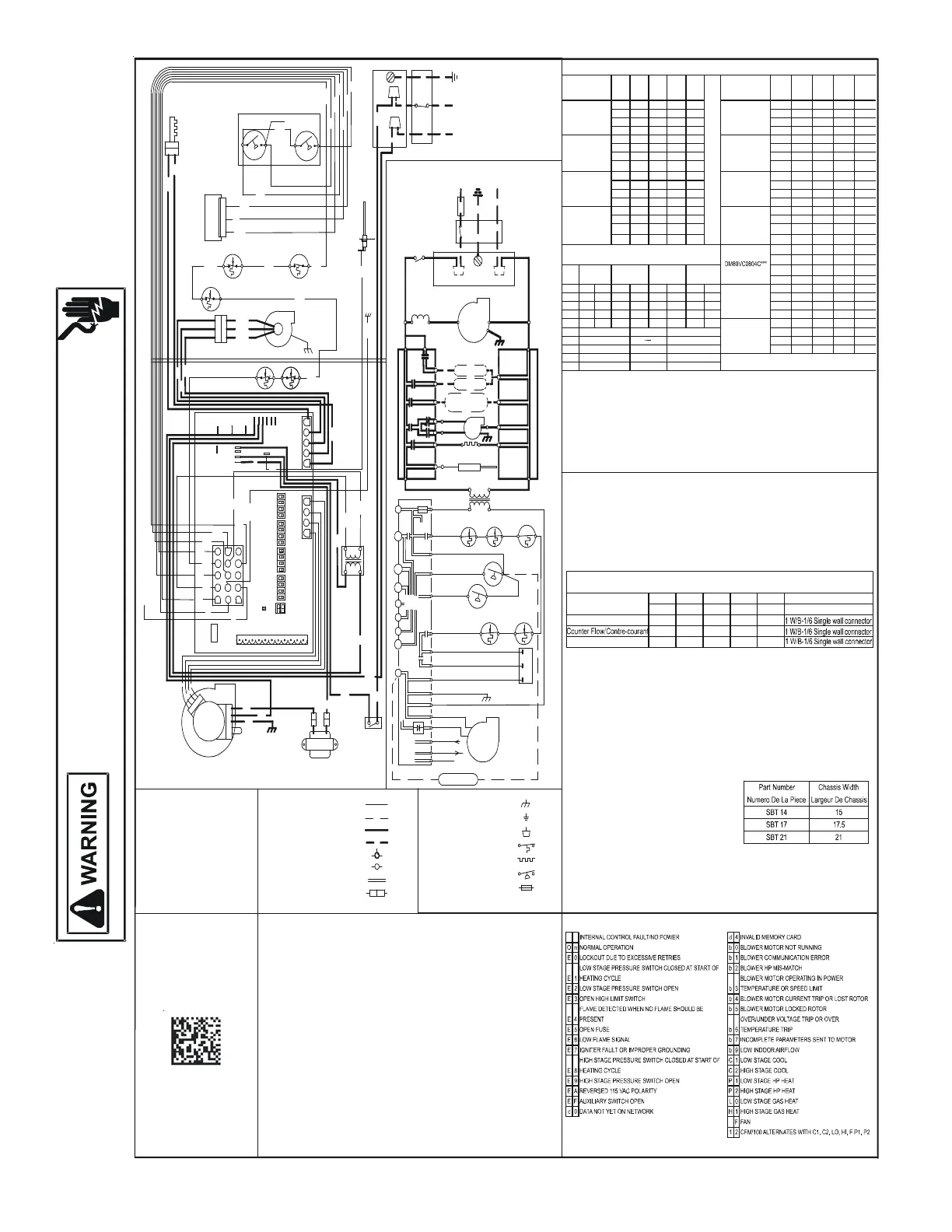

TAP

Low

Stage

Cool

High

Stage

Cool

Low

Stage

Heat

High

Stage

Heat

MODEL

TAP Low

Stage

Cool

High

Stage

Cool

Low

Stage

Heat

High

Stage

Heat

A 412 631 784 1107 A 468 698 735 1012

B 570 839 851 1198 B 584 847 804 1098

C 718 1050 922 1316 C 738 1034 874 1201

D842

1239

981 1407 D 872 1253 934 1310

A 423 643 690 937 A 390 600 875 1250

B 582 782 743 1045 B 520 800 945 1350

C 690 982 807 1155 C 715 1100 1015 1450

D 802 1200 870 1254 D 910 1400 1085 1550

A 532 817 976 1401 A 465 730 735 1012

B 732 1123 1048 1495 B 584 878 804 1098

C 942 1445 1121 1579 C 780 1056 874 1201

D 1197 1861 1192 1684 D 924 1224 934 1310

A 556 848 1150 1591 A 588 857 908 1234

B 838 1177 1188

1646

B 742 1051 986 1365

C 1031 1480 12111 1792 C 878 1284 1061 1501

D 1299 1881 1284 1790 D 1049 1616 1142 1618

A 520 800 1050 1500

B 715 1100 1120 1600

C 910 1400 1190 1700

D 1170 1800 1260 1800

Tap

S3- 1 S3- 2 S3- 3 S3- 4 S4-1 S4-2 S4- 3 S4-4

A 582 830 1386 1998

A

OFF OFF OFF OFF OFF OFF OFF OFF B 786 1139 1405 2007

B

ON OFF ON OFF ON OFF ON OFF C 1047 1561 1415 2022

C

OFF ON OFF ON OFF ON OFF ON D 1326 1966 1435 2047

D

ON ON ON ON ON ON ON ON A 520 800 1210 1725

Profile

B 715 1100 1225 1750

A

C 910 1400 1245 1775

B

D 1170 1800 1260 1800

C

D

60 sec @ 100%

---- 7.5 min @82%

60 sec @ 100%

To Set Airflow: (1) Select model and desired High Stage Cooling Airflow. Determine the corresponding tap (A, B, C, or D). Set dip

switches S3-1* and S3-2* to the appropriate ON/OFF positions. (2) Select model and desired High Stage Heating Airflow. Determine

The corresponding tap (A, B, C, or D). Set dip switches S4-3* and S4-4* to the appropriate ON/OFF positions. (3) Selecting Airflow

djustment Factor: For 0% trim set S5-2* to OFF (trim disabled). If trim is desired set S5-2* to ON (trim enabled) and set S3-3* and S3-4*

to appropriate ON/OFF positions. Tap A is +5%, Tap B is -5%, Tap C is +10%, Tap D is -10%. To Set Comfort Mode: Select

Desired Comfort Mode profile (see profiles above). Set dip switches S4-1* and S4-2* to the appropriate ON/OFF positions.

Dehumidification: To enable, set switch S5-1* to ON. Cooling airflow will be reduced to 85% of nominal value during cool call. To

disable, set switch S5-1* to OFF. Continuous Fan Speed: Set dip switches S5-3* and S5-4* to select one of 4 continuous fan speeds

(25%, 50%, 75%, or 100%). “See installation manual for details” *the “S” number refers to one of four labeled dip switch section each

containing 4 individual dip switches. The following number refers to the individual labeled dip switch within that section.

30 sec @ 50% 7.5 min @82%

30 sec @ 50%

DC80VC0805C*** DM80VC0803B***

DM80VC0804C***

Speed Selection Dip Switches

Cool Selection

Switches

Adjust Selection

Switches

Profile Selection

Switches

Heat Selection

Switches

DM80VC0805D***

DM80VC1005C***

DC80VC0803B***

DC80VC0603B***

MODEL

DM80VC0603B***

DM80VC0604B***

DC80VC1005C***

60 sec @ 100%

Pre-Run Off Delay Short Run

----

---- 30sec @ 50%

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C. AND LOCAL CODES.

REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE

3. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE FURNACE MUST BE

6. HUMIDIFIER INSTALLATION OPTIONS: USE HUM TERMINAL TO RUN HUMIDIFIER DURING HEAT CALL

2. MANUFACTURER’S SPECIFIED REPLACEMENT PARTS MUST BE USED WHEN SERVICING.

1. SET HEAT ANTICIPATOR ON ROOM THERMOSTAT AT 0.7 AMPS.

RATING OF AT LEAST 105°C. USE COPPER CONDUCTORS ONLY.

NOTES:

5. TO RECALL THE LAST 6 FAULTS, MOST RECENT TO LEAST RECENT, DEPRESS SWITCH

FOR MORE THAN 2 SECONDS WHILE IN STANDBY (NO THERMOSTAT INPUTS).

(COMMUNICATING OR LEGACY MODES). USE HUM-IN AND HUM-OUT TERMINALS TO RUN

HUMIDIFIER DURING HEAT CALL (COMMUNICATING MODE OR LEGACY MODE) OR INDEPENDENTLY

FROM HEAT CALL (COMMUNICATING MODE ONLY - SETUP IS DONE WITHIN COMMUNICATING

THERMOSTAT)

This furnace must be installed in accordance with the manufacturer’s instructions and local codes.

In the absence of local codes, follow the National Fuel Gas Codes. ANSI Z223.1, or CAN/CGA-b149

Installation Codes.

Ce générateur d’air chaud doit être installé conformément aux instructions du fabricant et aux

codes locaux. En l’absence de code local, respecter la norme ANSI Z223.1, Intitulé National Fuel

Gas Code ou les codes d’installation CAN/CGA-b149.

Line contact only permissible between lines formed by intersections of top and two sides of furnace

jacket, and building joists, studs or framing.

Les seuls points de contact admissible se trouvent entre les lignes formées par les intersections du

dessus et des deux côtés de l’enveloppe du générateur d’air chaud, et les solivers, les pout res ou

la charpente du bâtiment.

1) All positioning is determined as installed unit is view from front.

Tous les positions sont determinées telles que vues de l’avant de l’appareil installé.

2) Allow 24” minimum service clearance.

Prévoir un dégagement minimum de 24” pouces pour les interventions de dépannage.

+ For installation on combustible flooring.

Installer sur un plancher combustible.

# For installation on non combustible flooring only.*

Installer sur un plancher non combustible seulement.*

* For installation on combustible flooring only when

installed on special base Part no.

Pour les planchers combustibles, n’installer que sur

les socle spécial n*.

For use with natural gas and propane. A conversion kit as supplied by the manufacturer, shall be

used to convert this furnace to the alternate fuel.

Pour utilisation avec le gaz naturel et le propane. Une troussede conversion fournie par le fabricant

doit être utilisee pour passer d’un combustible a l’autre.

WH

FIELD INSTALL OPTION

GND

Minimum Clearance to Combustible Materials in Alcove or Closet installations (in.)

Dégagements minimum des matériaux pour une installation en alcôve ou en amoire (en pouces)

Position

Upflow/Courant ascendant

Horizontal/Horizontale

Sides

Côtes

Front

Avant

Rear

Amére

Top

Haut

Bottom

Bas

Vent

Ventilation

1

1

11

1

1

3

3

Alcove

0

0

0

+

#*

+

0140F02430-A

W

IRING

D

IAGRAM

DM

80

VC

/

DC

80

VC

Loading...

Loading...