46 | 180R9346 | AQ240486503020en-001702 © Danfoss | 2023.03

Operation guide Installation, Operation and Maintenance APP 53-92 pumps

3. Building up the

pump unit with BoWex

coupling

2.3 Preferred RO system design with ERD

For P&ID of a setup with an iSave, please see the

iSave® Data sheet 521B1378

2.4 Preferred RO system design with pumps

and ERDs in parallel

For systems with Danfoss pumps and ERDs in

parallel, please see our publication 180R9354,

Guideline for Parallel-coupled pumps and ERD.

2.5 Reversible pumps

If exposed to high-pressure in the outlet while

the electric motor is not energized, the pumps

may start spinning backwards. This will not harm

the pumps as long as the pressure in the inlet

does not exceed the max. pressure peak of

10 barg(145 psig).

If a non-return valve is mounted in the inlet line,

a low-pressure relief valve is required as protec-

tion against high-pressure pulses and high-pres-

sure in general.

Alternatively a high-pressure check valve can be

mounted in the pump discharge line to prevent

the pump from reversing.

The setup of “open-end system” ensures that the

inlet pressure does not exceed 10 barg (145 psig),

when a non-

return valve is mounted in the inlet.

2.6 General comments

A good ltration is vital to ensure a long and

trouble-free life of the pump.

As water has very low viscosity, the APP pumps

have been designed with very narrow clearance

in order to control internal leakage rates and

improve component performance. Therefore it is

important that the inlet water is ltered properly

to minimize the wear of the pump.

The main lter must have a ltration eciency of

99.98% at 10 m. We recommend to use

precision depth lter cartridges rated 10 m abs.

β10 ≥ 5000 (equivalent to a ltration eciency of

99.98%). Bag lters and string wounded lter

cartridges typically have only 50% ltration

eciency. This means that for each 100,000

particles reaching the lter, 50,000 particles pass

through it compared to only 20 particles in a

lter with an eciency of 99.98%.

For more information on the importance of

proper ltration, please see our data sheet

521B1009 on “Filtration”, which also will provide

you with an explanation of ltration denitions

and a guidance on how to select the right lter.

Monitoring

It is recommended to continuously monitor the

following conditions:

• Filter clogging

• Pressure (inlet- and outlet side of the pump)

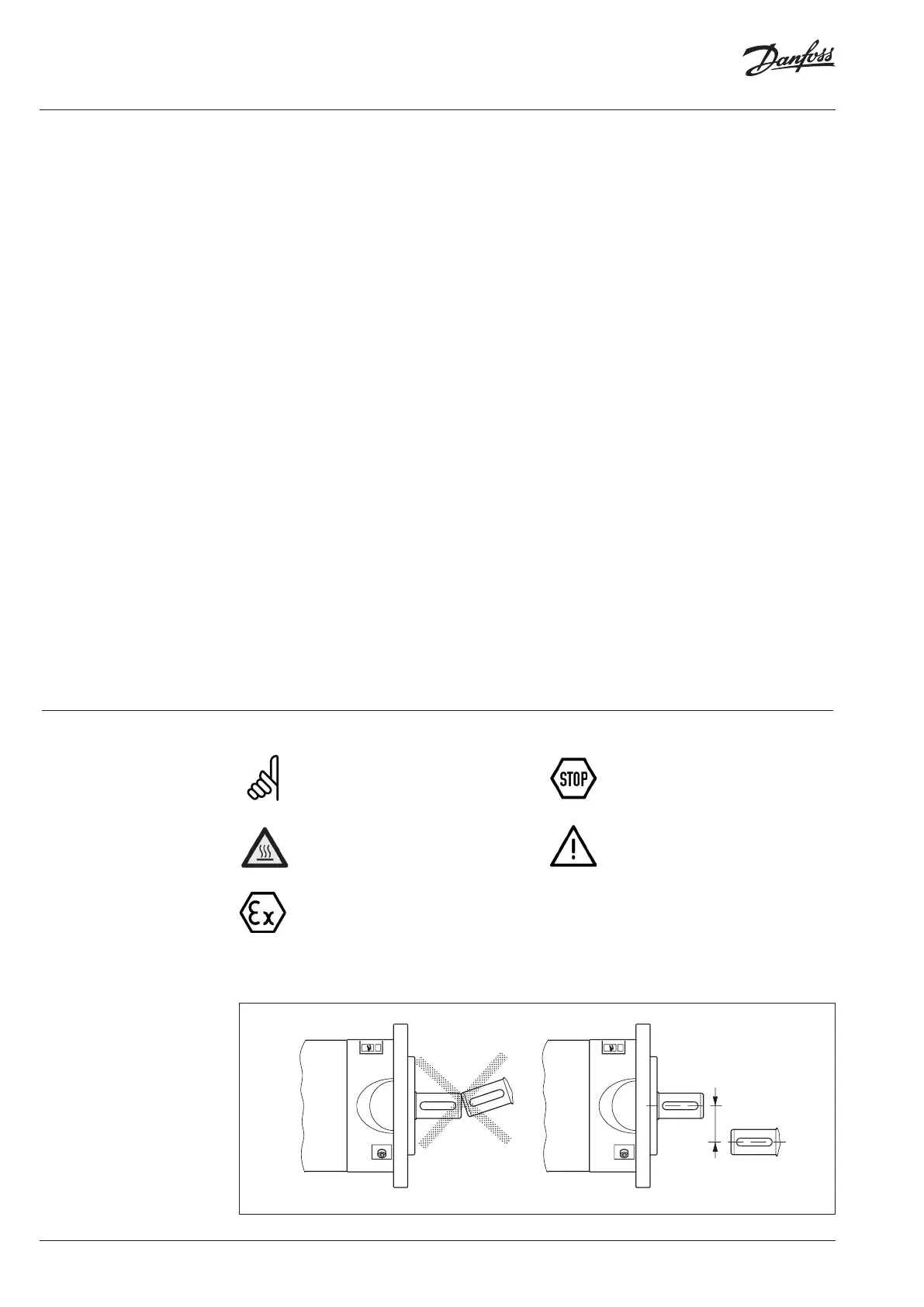

3.1 Assembly of the coupling

With the assembly please make sure

that the spline of the hub is fully co-

vered by the internal spline of elasto-

mer (please observe mounting dimen-

sions L

coupling

). Disregarding this advice

may cause damage to the coupling.

We recommend to inspect bores, shaft,

keyway and feather key for dimensional

accuracy before assembly.

Heating the hubs lightly (approx. 80 °C)

allows for an easier mounting on the

shaft.

Please pay attention to the ignition risk

in potentially explosive atmospheres!

Touching the heated hubs causes

burns.

Please wear safety gloves.

3.2 Alignment between the motor and

pump shaft

max. 0.5 mm

max. 0.02 inch

Loading...

Loading...