50 | 180R9346 | AQ240486503020en-001702 © Danfoss | 2023.03

Operation guide Installation, Operation and Maintenance APP 53-92 pumps

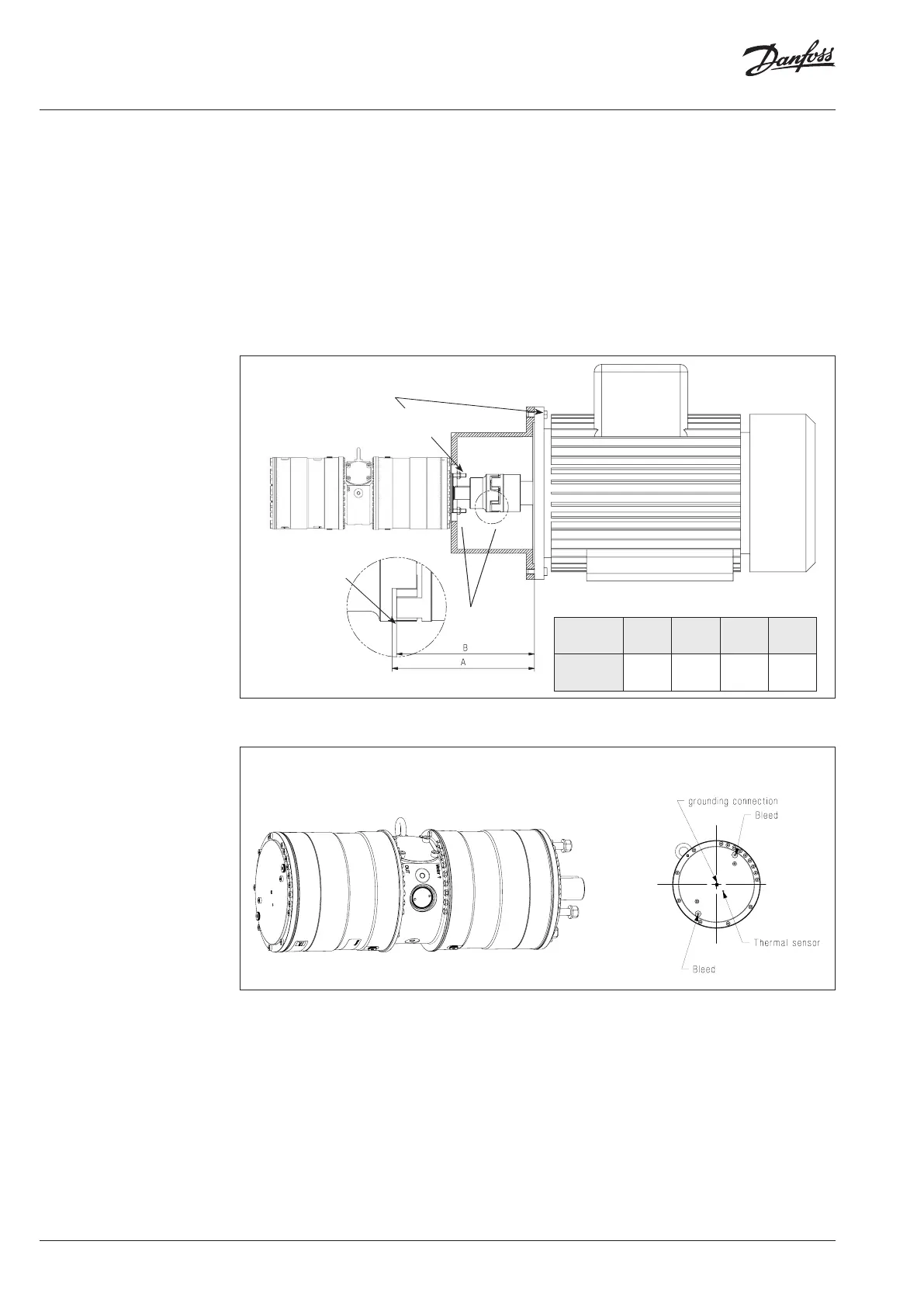

6. Adjust respectively, verify the measure-

ment, and secure both couplings with the

right torques on the locking screws (see

coupling operation & mounting instruction).

7. Mount the elastic gear ring and mount the

bell housing/pump on the motor. After

mounting it must be possible to move the

elastic gear ring 3-5 mm (0.12 - 0.2 inch)

axial “C”. The check can be done through

the inspection hole of bell housing. Secure

ange bolts with the right torque.

If alternative mounting is desired, please contact

Danfoss High Pressure Pumps.

Choose proper tolerances to ensure an easy

mounting of the elastic coupling without use of

tools.

Please take care to observe the recommended

length tolerances of the chosen coupling, as an

axial force on the pump will damage the pump.

C

75 Nm ± 5 Nm

1: Bolts 100 Nm ± 10

2: Nuts 100 Nm ± 10

3: Torque se table below

Thread

size

M5 M6 M8 M10

Torque

[Nm]

2 4.8 10 17

2

1

3

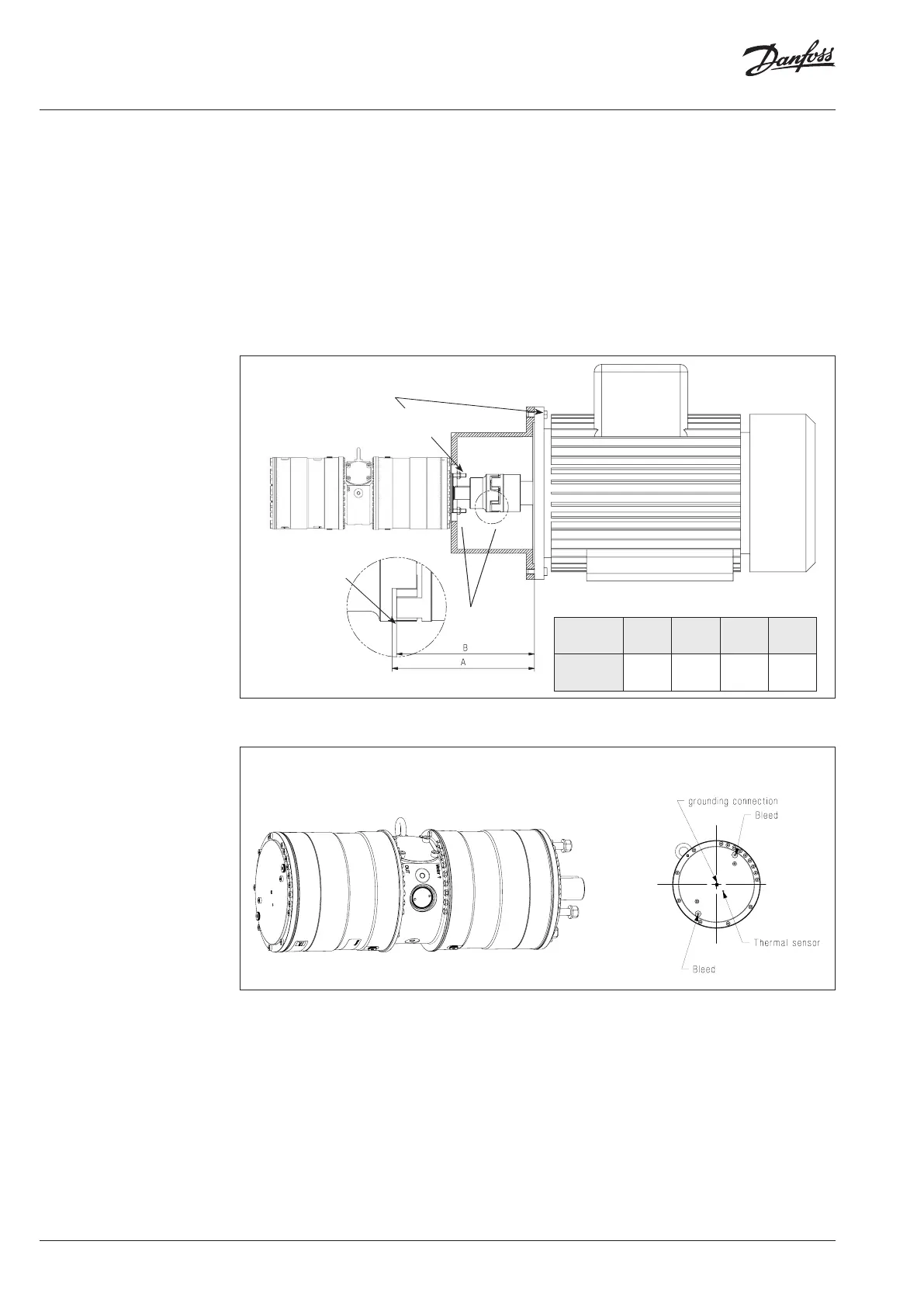

4.2 Connections

To prevent stray current corrosion we recom-

mend grounding of the pump and all other parts

in the system.

All parts in the system must be electrical

potential equalized to a single reference point

(grounding point).

It is recommended that the electrical resistance

in the grounding cable is equal to or below 0.25

Ohm towards the grounding point.

Loading...

Loading...