Top cover / function module

1.

1.1.

1.2.

1.3.

1.4.

2.

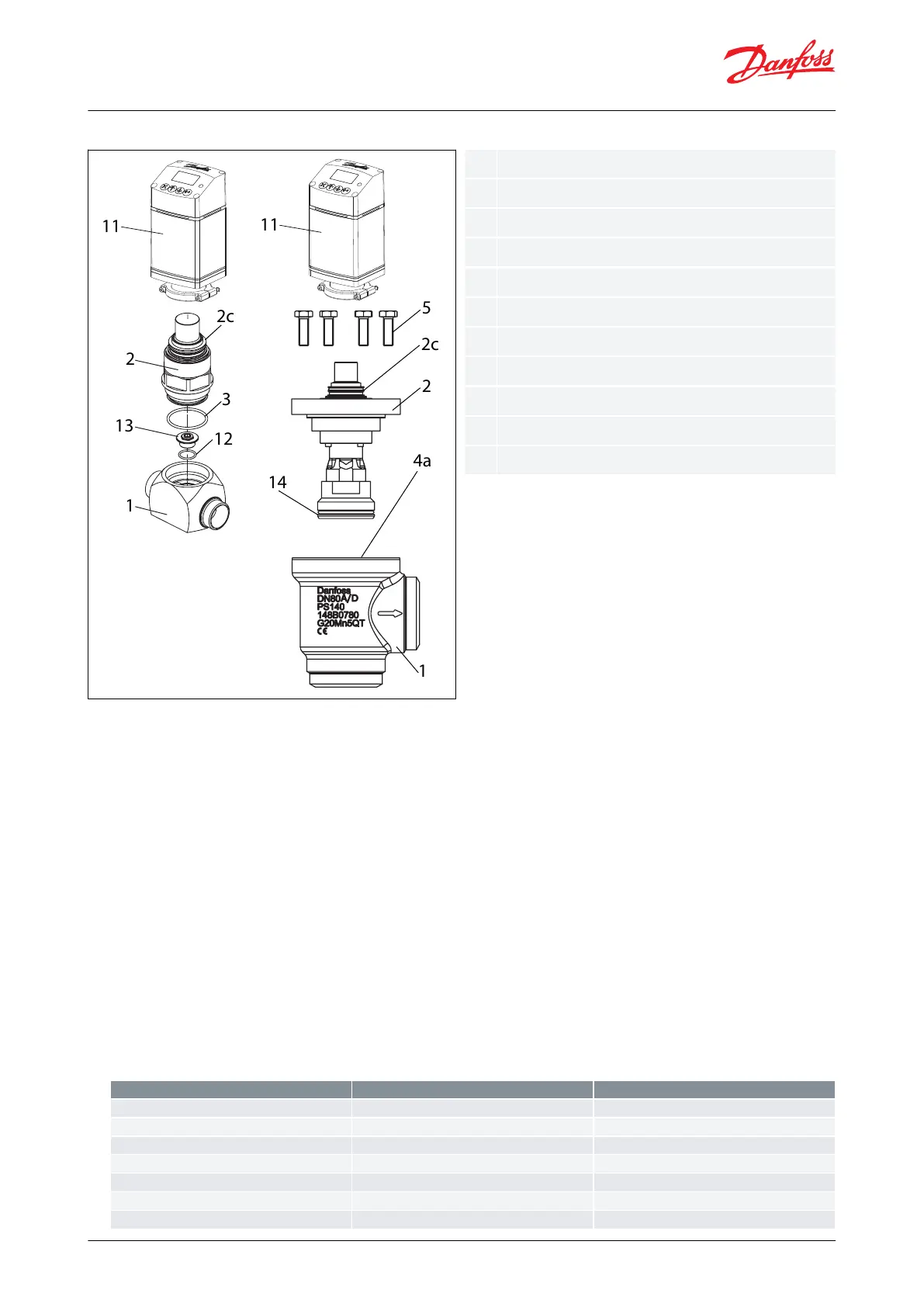

Figure 4: ICMTS 20 and ICMTS 50/80

CAUTION:

Care should be taken to protect the ICM/ICMTS function module when it is removed and stored during installation

of valve body.

Weld the valve body in line making sure that the arrow on the valve body is pointing in the direction of ow

For ICM 20 through 65 and ICMTS 20 through 80, make sure that all debris is removed from valve body

before bonnet/ function module is re-installed

For the ICM 20 and ICMTS 20, make sure that the removable orice seat is re-installed in the valve body

with the small o-ring between the orice seat and the body. Use a 13mm socket to tighten the 20-A33 or

20-A valve seat to a torque of 6.5 ft-lbs (9 N-m). Use a 12 mm hex key to tighten the 20-B66, 20-B or 20-C

valve seat to a torque of 1.5 ft-lbs (2 Nm)

DO NOT OVERTIGHTEN THE REMOVABLE SEAT.

Make sure that the bonnet gasket or bonnet o-ring for ICMTS 20 is installed and in good condition.

For the ICM 25 through ICM 65, check that the two o-rings are installed on the function module and that

the gasket located on the top of the valve body is installed and all are in good condition. A light coating of

refrigerant oil on the bonnet o-rings and the cover gasket will facilitate assembly of the valve

For the ICMTS 50/80, check that the o-ring is installed on the function module and that the gasket located

on the top of the valve body is installed and all are in good condition. A light coating of refrigerant oil on

the bonnet o-ring and the cover gasket will facilitate assembly of the valve

Install the bolts and torque to the following specications:

© Danfoss | Climate Solutions | 2024.01 BC465027827472en-000102 | 7

ICM and ICMTS Motorized Valves with ICAD Actuators

Loading...

Loading...