3.

3.1.

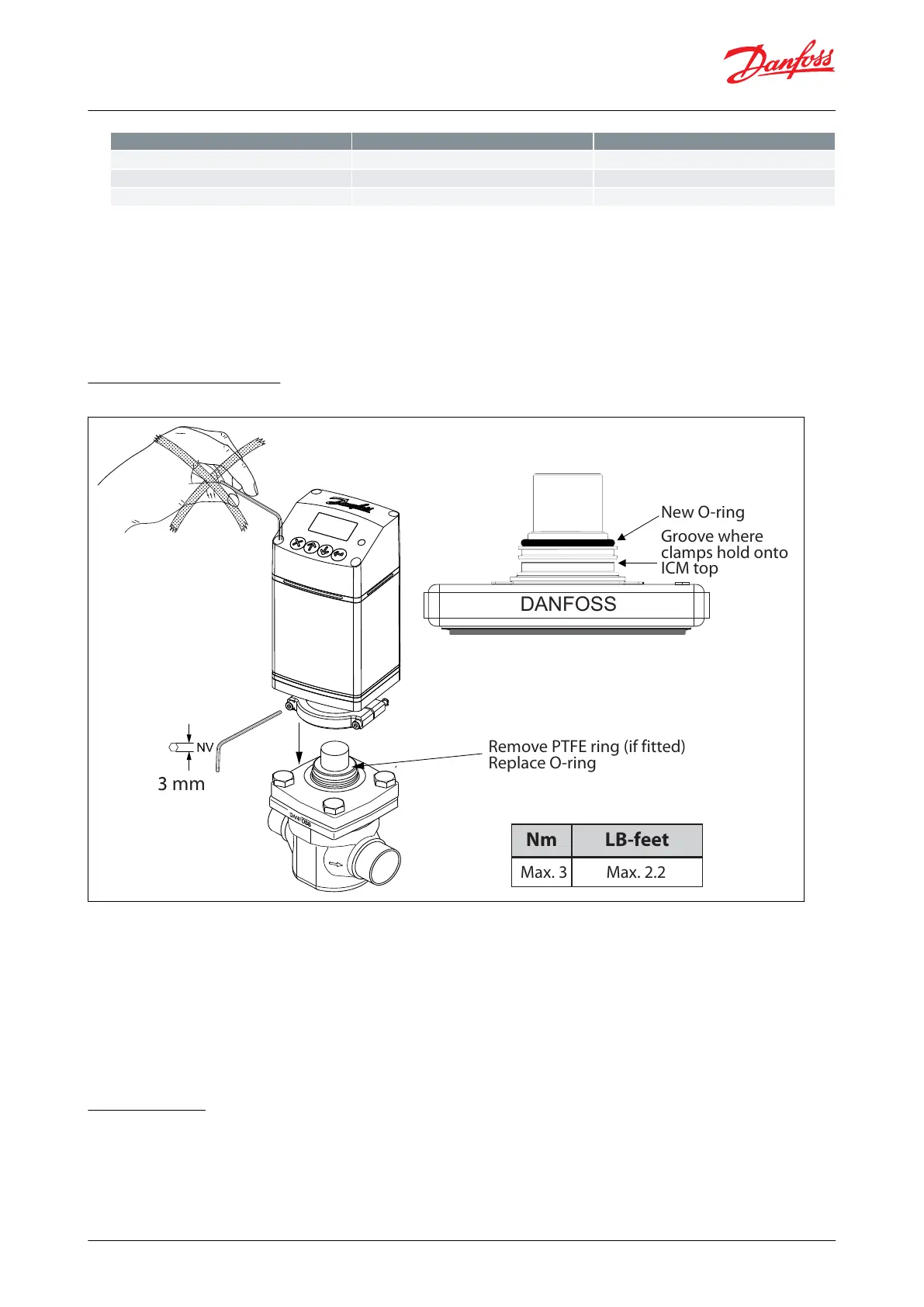

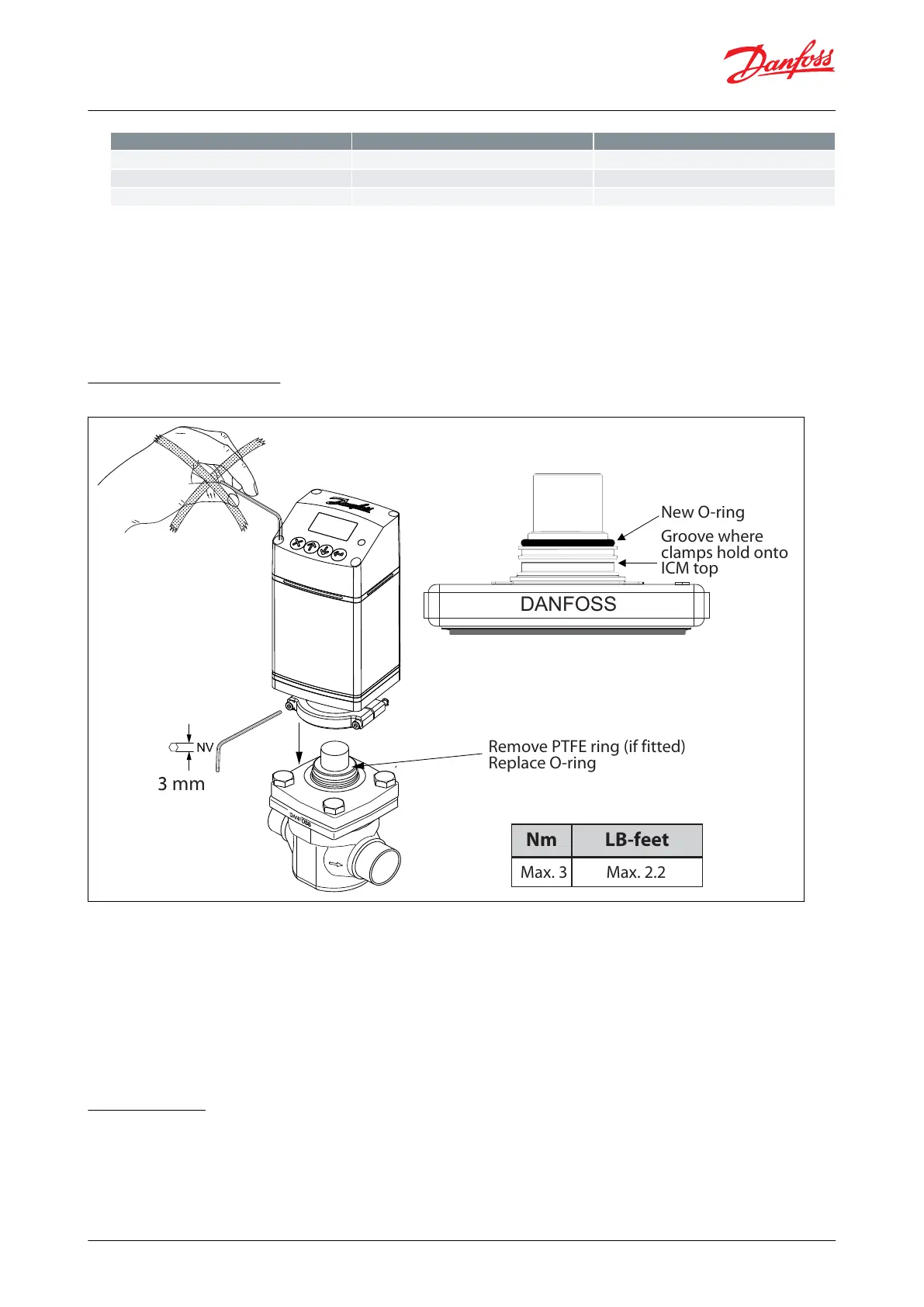

Install the ICAD Motor on the ICM/ICMTS valve:

The ICM/ICMTS valve must not be in its full opened position while the ICAD motor is calibrated with the valve (at a

later step). Therefore, if the opening degree of the ICM/ICMTS valve was changed from the factory setting, it

should be set to an opening degree between 0% and 75% using the manual magnet tool. To easily ensure

correct positioning, turn the manual tool counter-clockwise until it is clear that it cannot be turned any further.

Make sure that the ICM/ICMTS adapter/valve stem and inner ICAD magnets are completely dry and free

from any debris

Mechanical installation

Figure 5: Procedure for ICAD installed on all valves

Nm LB-feet

mm

Groove where

clamps hold onto

ICM top

Remove PTFE ring (if fitted)

Replace O-ring

New O-ring

DANFOSS

Max. 3 Max. 2.2

General procedure for ICAD 600B/ICAD 600B-TS/1200B installed on all valves

• Check that the two socket screws are fully unscrewed counter clockwise with a 3 mm Hexagon key

• If valve is tted with PTFE ring and O-ring, remove both and replace it with O-ring included in ICAD (as instructed

in

Figure 5)

• Mount ICAD by slowly lowering it on top of the valve

• The magnet coupling will drag the valve and ICAD together and in position

• Push ICAD in place

• Fasten valve and ICAD with the two socket set screws using a 3 mm Hexagon key

Electrical data

Supply voltage is galvanically isolated from in-/output. ICAD is a Class III product.

PSUs connected to ICAD must be SELV<100 VA

For UL compliance: PSU must be Class 2 NEC

ICM and ICMTS Motorized Valves with ICAD Actuators

© Danfoss | Climate Solutions | 2024.01 BC465027827472en-000102 | 8

Loading...

Loading...