Overview

This section provides general steps to follow if you observe undesirable system conditions. Follow the

steps listed until you solve the problem. Some of the items are system specific. We reference the section

in this manual if more information is available. Always observe the safety precautions listed in the

Introduction section and precautions related to your specific equipment.

Safety Precautions

Warning

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. Relieve pressure in the system before removing hoses, fittings, gauges, or

components.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Caution

Contamination can damage internal components and void the manufacturer’s warranty. Take

precautions to ensure system cleanliness when removing and reinstalling system lines

Warning

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state, and federal enviroN•mental regulations.

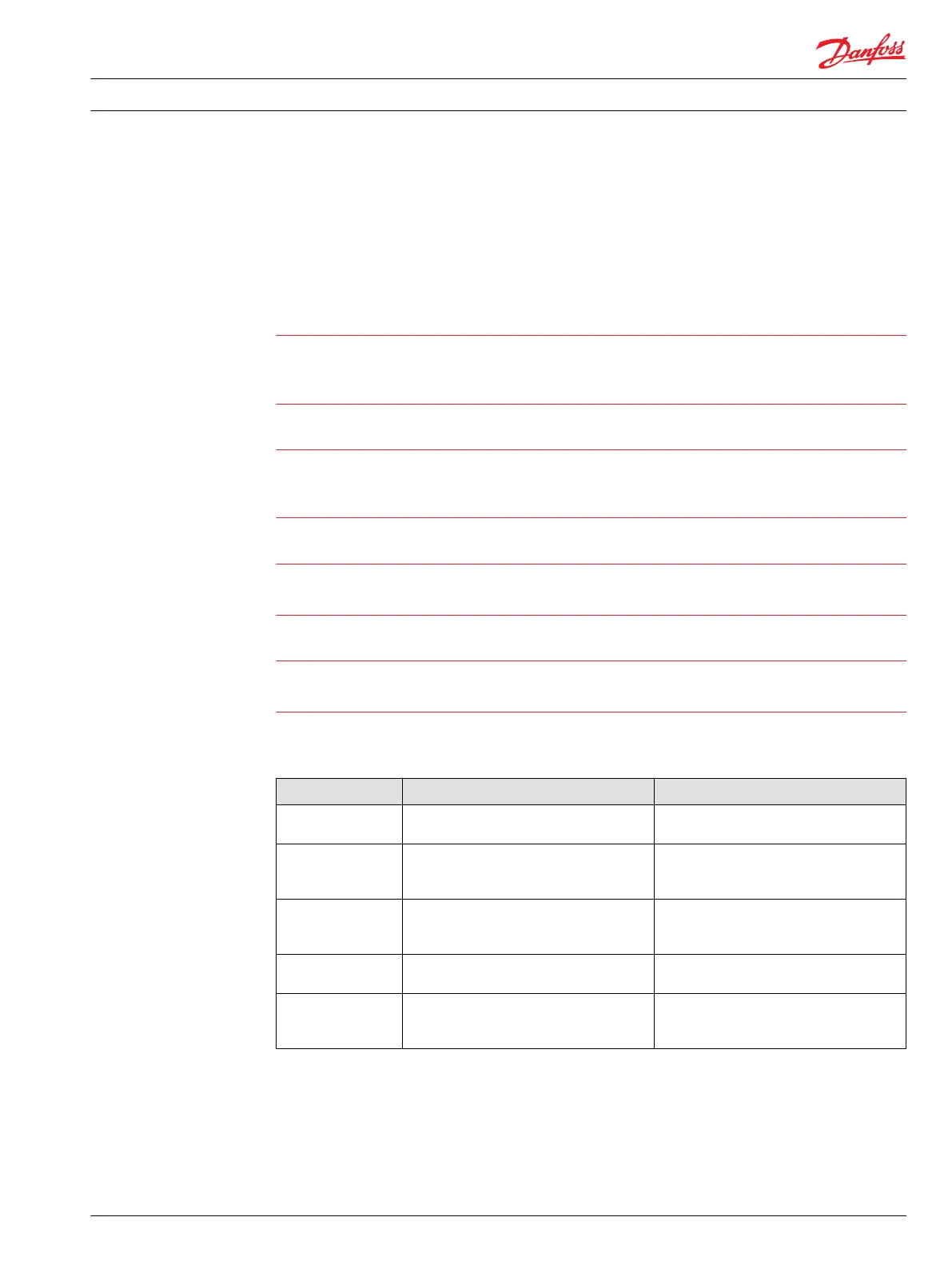

System operating hot

System operating hot

Item Description Action

Oil level in reservoir. Insufficient hydraulic fluid will not meet

cooling demands of system.

Fill reservoir to proper level.

Heat exchanger. Heat exchanger is not sufficiently cooling the

system.

Check air flow and input air temperature for

heat exchanger. Clean, repair or replace heat

exchanger.

System relief pressure

settings

If the system relief valves are worn,

contaminated, or valve settings are too low,

the relief valves will be overworked.

Verify settings of high pressure relief valves

and replace valves as necessary.

System pressure Frequent or long term operation over system

relief setting will create heat in system.

Measure system pressure. If pressure is too

high, reduce loads.

For internal leakage

in motor

Leakage will reduce low side system pressure

and overwork the system.

Monitor motor case flow without loop

flushing in the circuit. If flow is excessive,

replace motor.

Service Manual TMM Transit Mixer Axial Piston Motor, Size 070/084/089

Troubleshooting

L1211037 • Rev AC • Apr 2014 19

Loading...

Loading...