FCM 300 / FCD 300 / VLT

®

2800 / DP V1 PROFIBUS

The Profibus

Interface

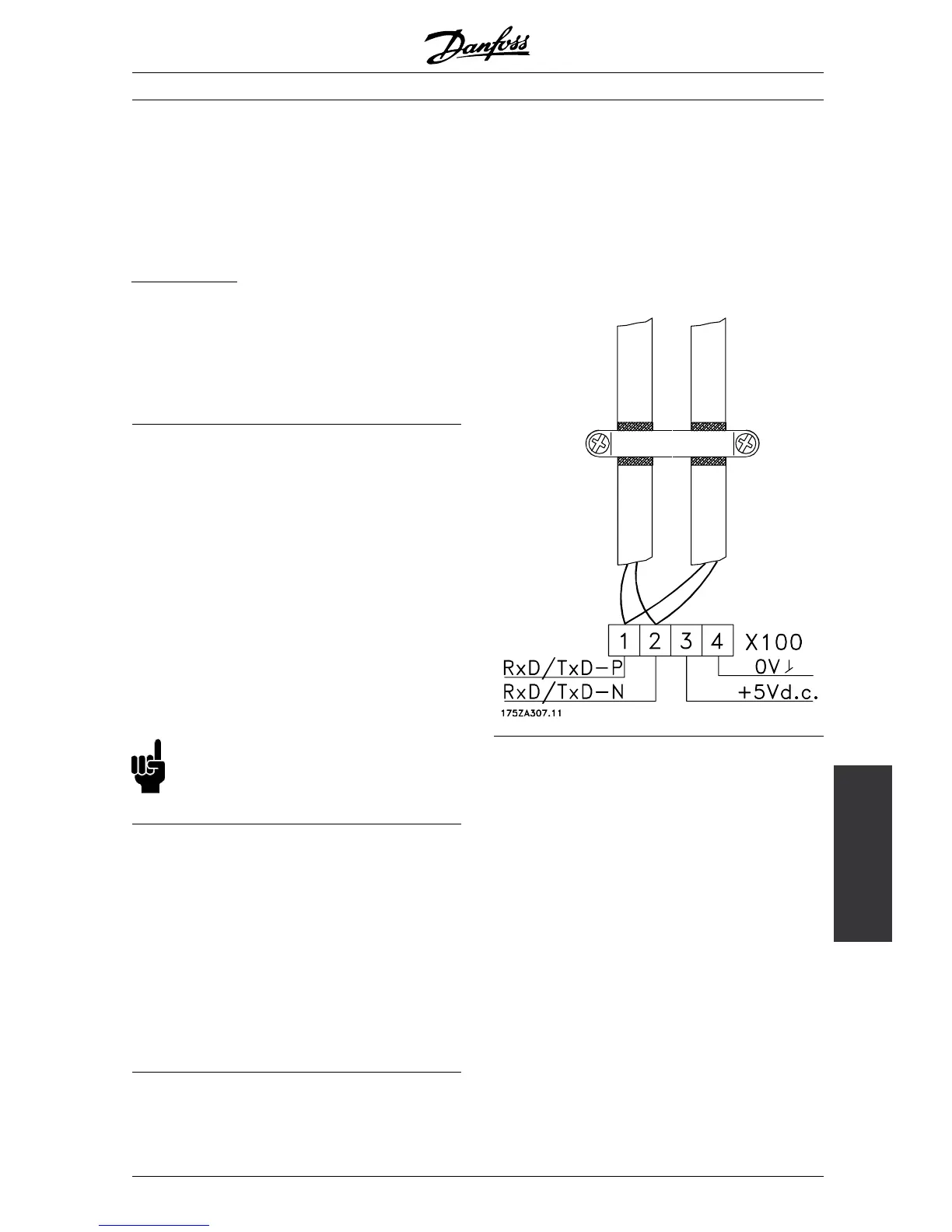

■ Physical connection

The PROFIBUS is connected to the b us line

via X100, terminals 1 and 2.

It is recommended to use a master with a

galvanic isolated bus driver and with over voltage

protection (e.g. zenerdiode).

E

MC precautions

The following EMC precautions are recommended to

obtain interference free operation o f the PROFIBUS

network. Additional information on EMC can be found

in the design guide on the FCM 300 (MG.03.BX.02).

Please also consult the manual of the PROFIBUS

master for further installation guidelines.

■ Connection of the cable screen

The screen of the PROFIBUS c able must always

be connected to ground at both ends, that means

the screen must be connected to ground in all

stations connected to the PROFIBUS network. It

is very important to have a low impedance ground

connection of the screen, also at high frequencies.This

can be obtained by connecting the surface of the

screen to ground, fo r example by m eans of a cable

clamp or a conductive cable gland.

The FCM 300 Series is provided with different clamps

and brackets to enable a proper ground conn ection of

the PROFIBUS cable screen. The screen connection

is shown in the following drawing.

NB!:

Relevant national and local regulations,

for example regarding protective earth

connection, must be observed.

■ Cable connection FCM 300

The PROFIBUS communication cable must be kept

away from motor a nd brake resistor cab les to avoid

coupling of high frequency noise from one cable to

the other. Normally a distance of 200 mm is sufficient,

but it is generally recommended to keep the greatest

possible distance between the cables, especially whe re

cables are running in parallel over long distances.

If the PROFIBUS cable has to cross a motor and

braking resistance cable, i t should occur a t a 90° angle.

■ Earth connection

It is important that all stations connected to the

PROFIBUS network are connected to the same

earth potential. The earth connection must have

a low HF (high frequency) impedance. This c an

be achieved by connecting a large surface area of

the cabinet to earth, for example by mounting the

FC motor on a conductive rear plate.

Especially when having long distances between the

stations in a P ROFIBUS network it can be necessary to

use additional potentia l equalizing cables, c onnecting

the individual stations to the same earth potential.

MG.90.A5.02 - VLT is a registered Danfoss trademark

11

Loading...

Loading...