FCM 300 / FCD 300 / VLT

®

2800 / DP V1 PROFIBUS

Profibus DP

■ DP communication relations

Communication according to PROFIBUS DP, i.e. EN

50170 part 3, is supported. Consequently a master

that supports PROFIBUS DP must be used.

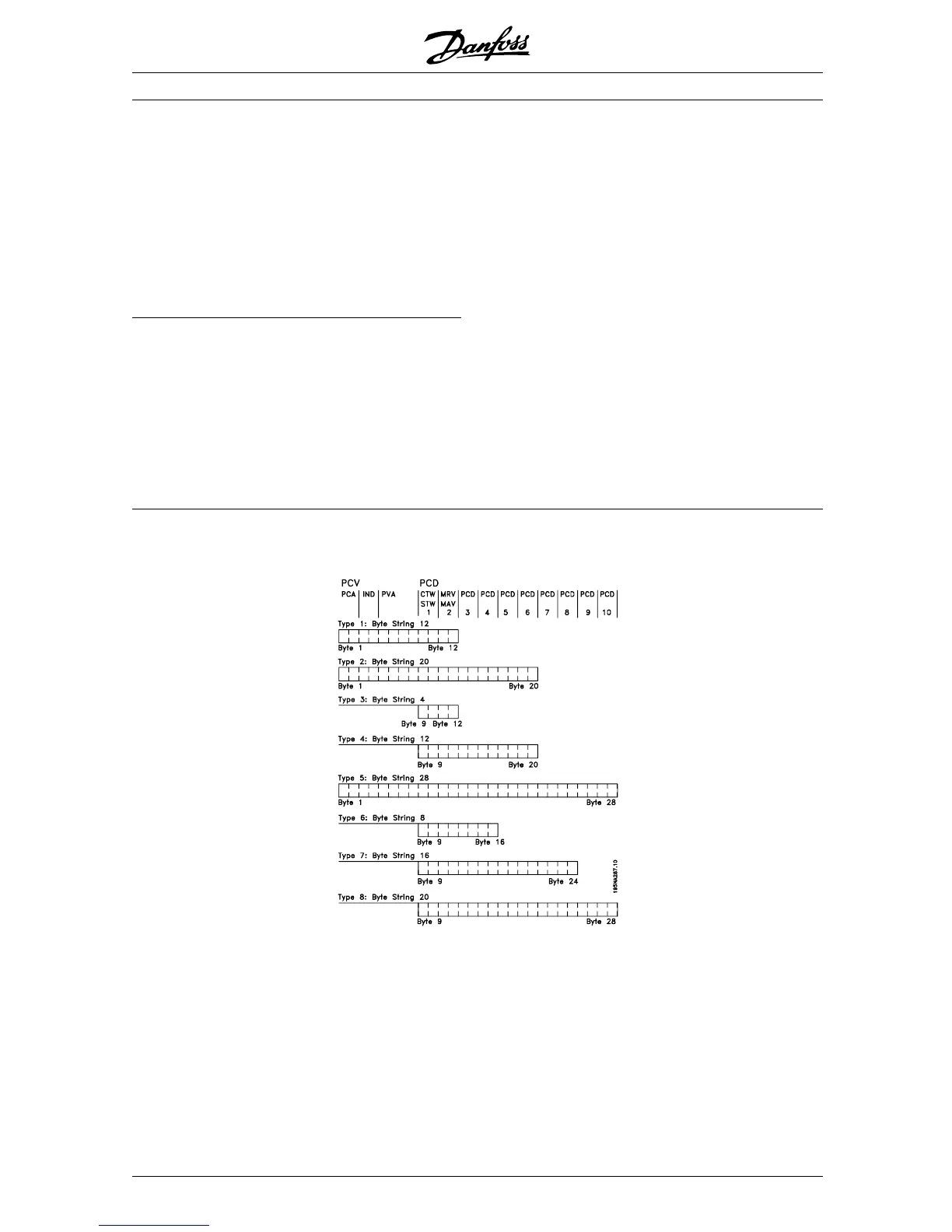

By DP communication one of the parameter-process

data objects (PPO’s) described below must be used.

■ PPO description

A special feature of the PROFIBUS Profile for frequency

converters is the communication object called a PPO,

meaning Parameter-Process D ata Object.

The PPO is well suited for fast cyclical data

transfer, and may, as the name implies, carry both

process data and parameters .

The selection of PPO type is made according

to the master configuration.

A PPO may consist of a parameter part and process

data pa rt. The parameter part can be used for reading

and/or updating the parameters one by one. The

process data part consists of a fixed part (4 bytes)

and a parametrable part (8 or 16 bytes). In the fixed

part control word and speed reference are transfered

to the frequency converter while status word and

actual output frequency feedbac k are transfered

from the frequency converter. In the parametrable

part the user chooses which parameters have to

be transfered to (parameter 915) and w hich from

(parameter 916) the frequency converter.

PPO. Parameter-Process Data Object

By DP one of the following shown PPO’smustbeused:

PCD: Process Da

ta

PCV: Parameter-

Characteristics-Value

PCA: Parameter-C

haracteristics (Bytes 1, 2)

(PCA handling s ee section PCA handling)

IND: Subindex (Byte 3), (Byte 4 is not used)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control word see section Control word

STW: Status word see section Status word

MRV: Main reference value

MAV: Main actual value (Actual output frequency)

MG.90.A5.02 - VLT is a registered Danfoss trademark

20

Loading...

Loading...