VLT

®

5000 Series

Torque control, speed feedback, is selected if it is to

be possible to change the speed direction, while at

the same time maintaining the torque reference.

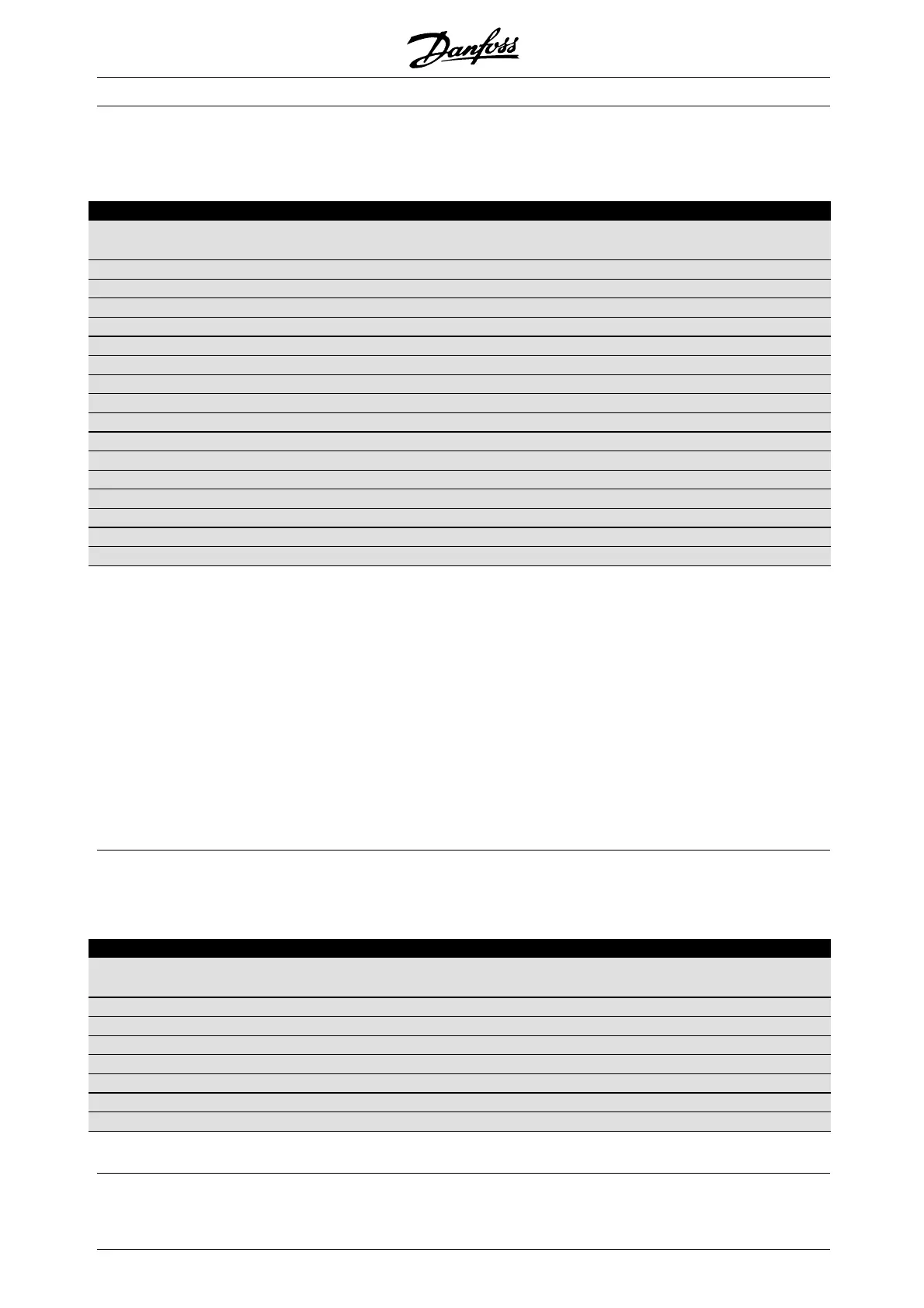

Set the following parameters in order shown:

Torque control, speed feedback:

Parame-

ter:

Setting: Data value:

100 Configuration Torque control, speed feedback [5]

200 Output frequency, range/direction

201 Output frequency, low limit

202 Output frequency, high limit

203 Reference/feedback range

204 Minimum reference Only if [0] in par. 203

205 Maximum reference

414 Minimum feedback

415 Maximum feedback

306 Encoder feedback, input B [24]

307 Encoder feedback, input A [25]

329 Encoder feedback, pulse/rev

421 Speed PID low-pass filter time

448 Gear ratio

447 Torque regulation, speed feedback

449 Friction loss

After Torque control, speed feedback, has been

selected, the frequency converter should be calibrated

to ensure that the current torq

ue equals the torque

of the frequency converter. For this to be ensured,

a torque gauge must be fitted to the shaft so as to

enable accurate adjustmen

t of parameter 447, Torque

compensation , and parameter 449, Friction loss.Itis

recommended to run an AMA before torque calibration.

Proceed as follows be

fore beginning to use the system:

1. Fit a torque gauge to

the shaft.

2. Start the motor with a positive torque reference and a

positive direction of rotation. Read the torque gauge.

3. Using the same torque reference,

change the

direction of rotation from positive to negative.

Read the torque and adjust it to the same

level as for the positive torq

ue reference and

direction of rotation. This can be done by means

of parameter 449, Friction loss.

4. Using a warm motor and app

rox. 50% load,

set parameter 447, Torque compensation,to

match the torque gauge. The frequency converter

is now ready for opera

tion.

Select Special motor characteristics if the

frequency converter is to be adapted to a

synchronous motor, parallel motor operation or if

slip- compensation is not required.

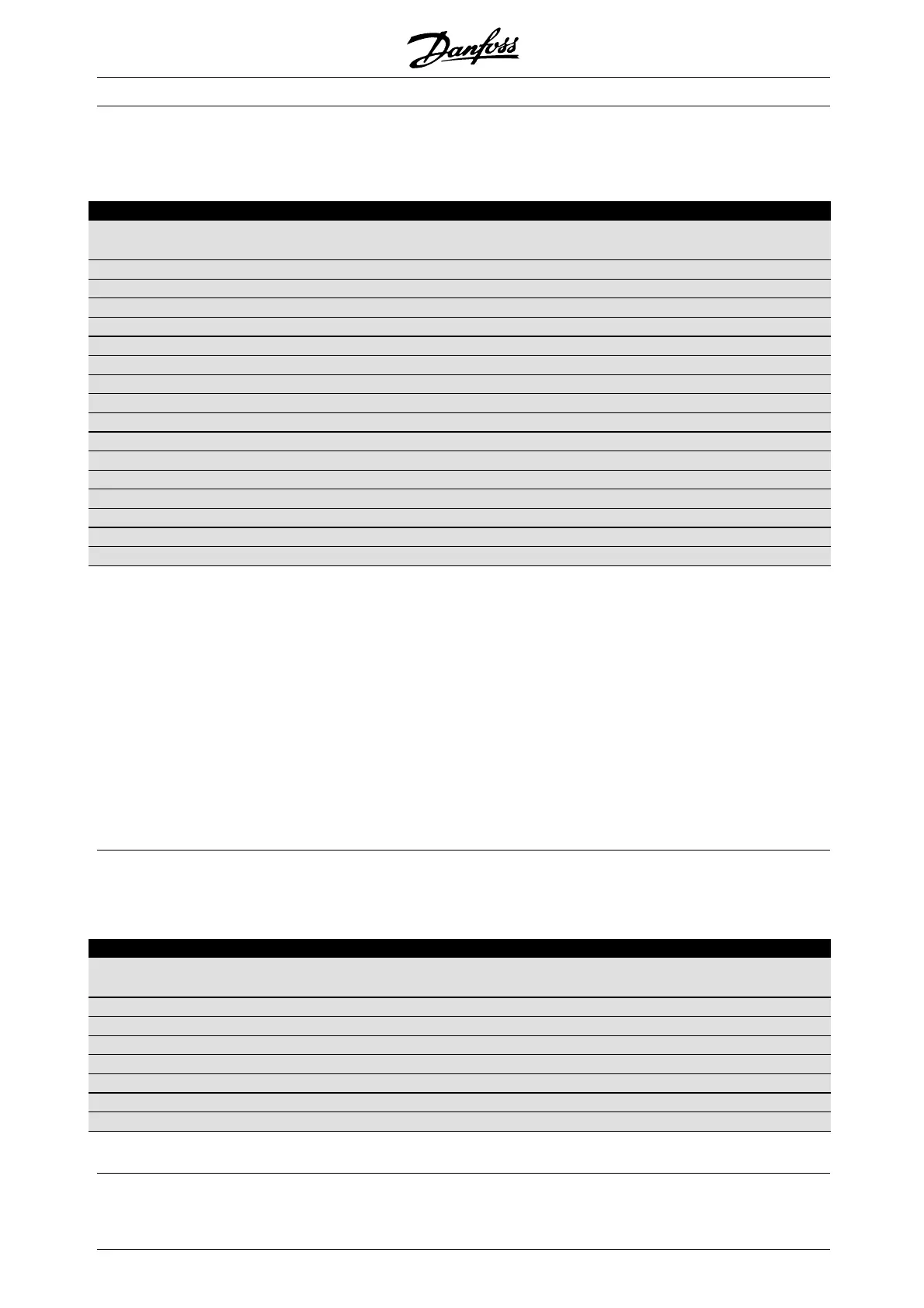

Set the fol

lowing parameters in order shown:

Sp

ecial motor characteristics:

Par

ame-

ter:

Set

ting:

Dat

avalue:

101 Torque characteristics Special motor characteristics [5] or [15]

432 + 431 F5 frequency/U5 voltage

430 + 429 F4 frequency/U4 voltage

428 + 427 F3 frequency/U3 voltage

426 + 425 F2 frequency/U2 voltage

424 + 423 F1 frequency/U1 voltage

422 U0 voltage

MG.51.A9.02 - VLT is a registered Danfoss trademark

78

Loading...

Loading...