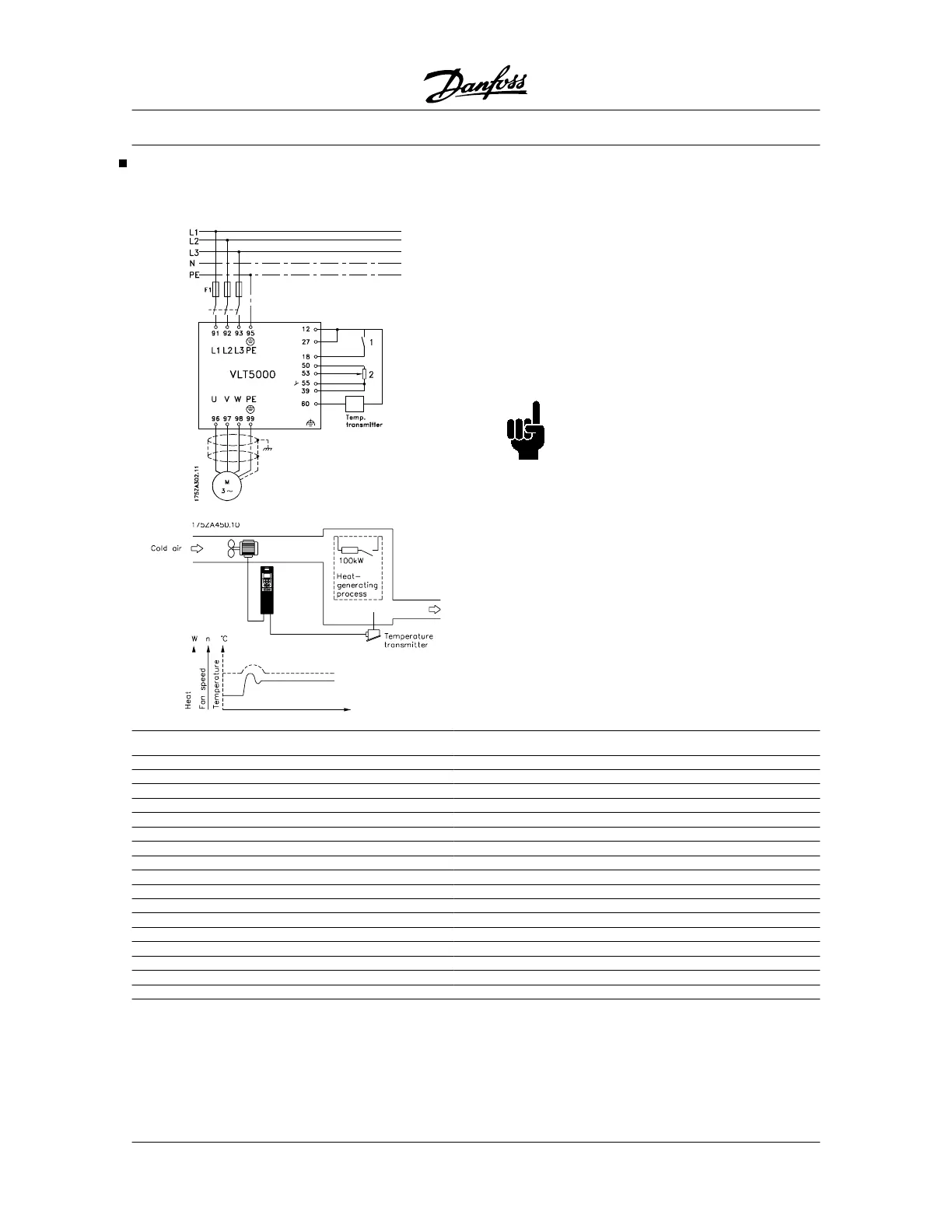

PID for process control

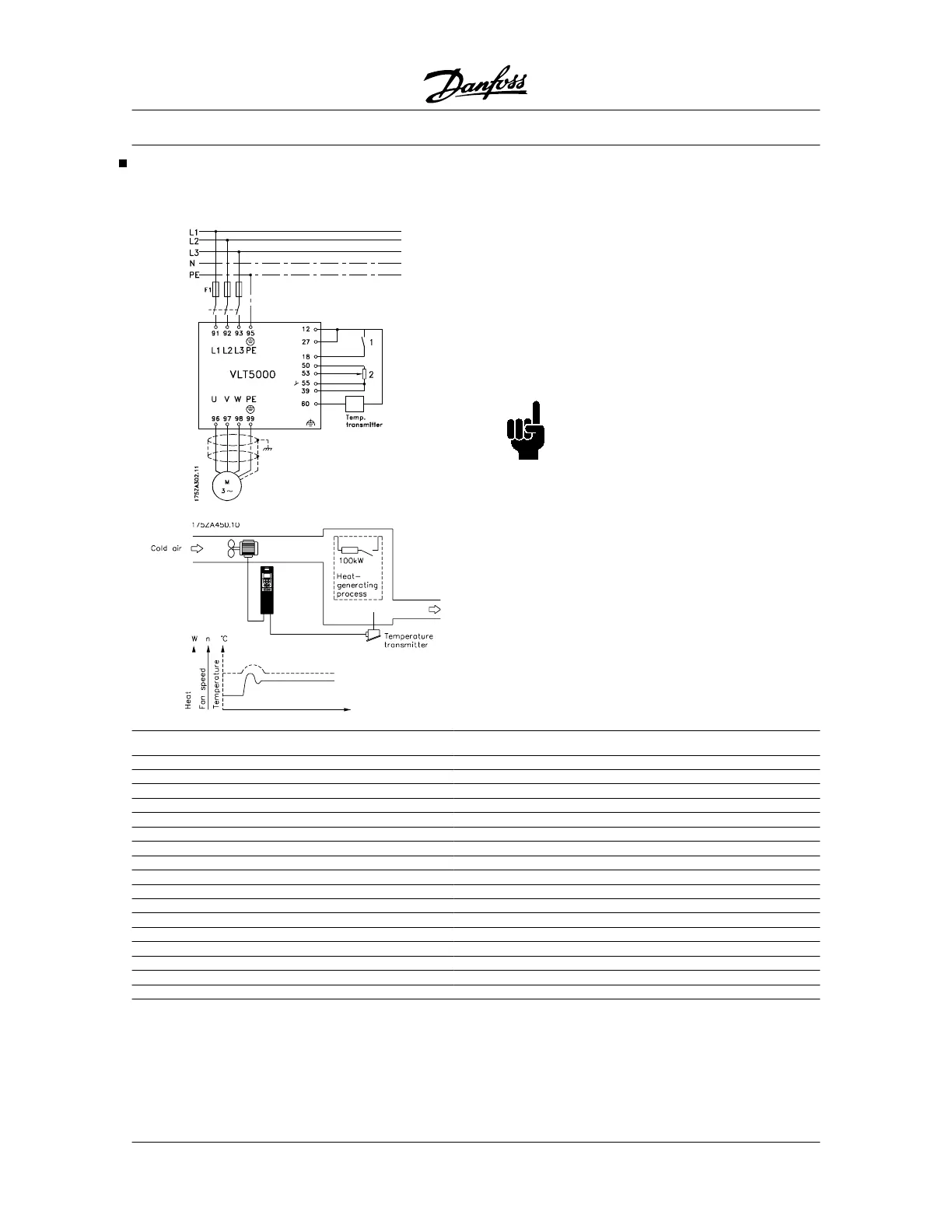

The following is an example of a process controller

used in a ventilation system.

In a ventilation system, the temperature is to be setta-

ble from - 5 - 35°C with a potentiometer of 0-10 Volt.

The set temperature must be kept constant, for which

purpose the integrated process controller is to be

used.

The control is of the inverse type, which means that

when the temperature increases, the ventilation speed

is increased as well, so as to generate more air. When

the temperature drops, the speed is reduced.

The transmitter used is a temperature sensor with a

working range of -10-40°C, 4-20 mA.

Min./Max. speed 10/50 Hz.

NOTE

The example shows a two-wire transmit-

ter.

1. Start/Stop

2. Temperature reference -5-35°C, 0-10 V (set-

point)

3. Temperature transmitter -10-40°C, 4-20 mA

(feedback).

The following must be programmed in order shown - see explanation of settings in the Operating Instructions:

Function:

Parameter no. Setting Data value no.

Activation of process controller 100

Process control, closed loop

[3]

Feedback signal 314

Feedback signal

[2]

Terminal 60, min. scale 315 4 mA

Terminal 60, max. scale 316 20 mA (factory setting)

Minimum feedback 414 -10°C

Maximum feedback 415 40°C

Process units 416 °C [10]

Reference 308

Reference (factory setting)

[1]

Terminal 53, min. scale 309 0 Volt (factory setting)

Terminal 53, max. scale 310 10 Volt (factory setting)

Minimum reference 204 -5°C

Maximum reference 205 35°C

Inverse control 437

Inverse

[1]

Min. frequency 201 10 Hz

Max. frequency 202 50 Hz

Proportional gain 440

Application-dependent (e.g. 1.0)

Integration time 441

Application-dependent (e.g. 5 sec.)

VLT

®

5000 Series

174 MG.51.C5.22 - VLT

p

is a registered Danfoss trademark.

Loading...

Loading...