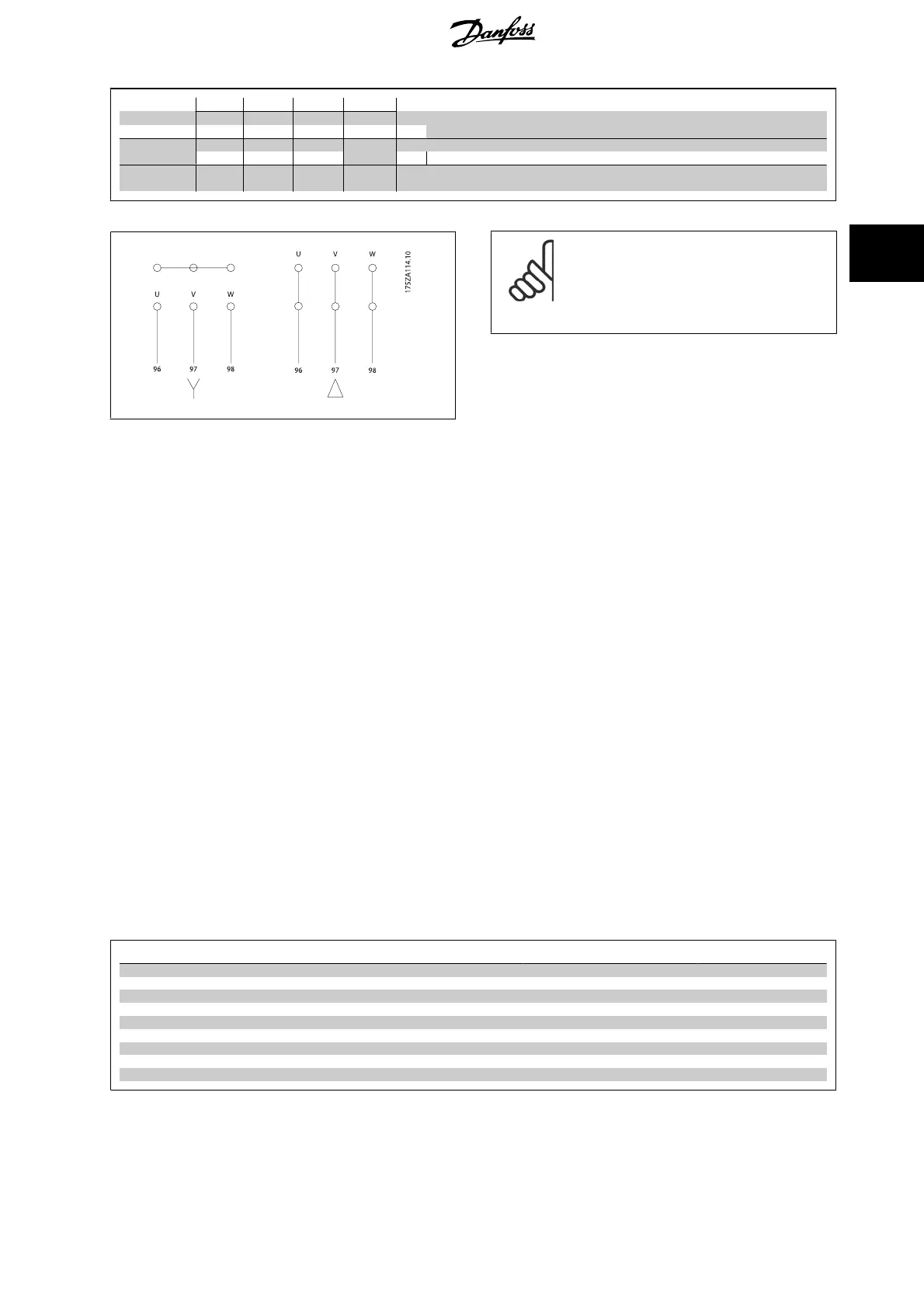

Term. no. 96 97 98 99

U V W

PE

1)

Motor voltage 0-100% of mains voltage.

3 wires out of motor

U1 V1 W1

PE

1)

Delta-connected

W2 U2 V2 6 wires out of motor

U1 V1 W1

PE

1)

Star-connected U2, V2, W2

U2, V2 and W2 to be interconnected separately.

1)

Protected Earth Connection

NB!

In motors without phase insulation paper or other in-

sulation reinforcement suitable for operation with volt-

age supply (such as a frequency converter), fit a Sine-

wave filter on the output of the frequency converter.

3.3.5 Fuses

Branch circuit protection:

In order to protect the installation against electrical and fire hazard, all branch circuits in an installation, switch gear, machines etc., must be short-circuited

and overcurrent protected according to national/international regulations.

Short-circuit protection:

The frequency converter must be protected against short-circuit to avoid electrical or fire hazard. Danfoss recommends using the fuses mentioned below

to protect service personnel and equipment in case of an internal failure in the drive. The frequency converter provides full short-circuit protection in case

of a short-circuit on the motor output.

Overcurrent protection:

Provide overload protection to avoid fire hazard due to overheating of the cables in the installation. The frequency converter is equipped with an internal

overcurrent protection that can be used for upstream overload protection (UL-applications excluded). See par. 4-18

Current Limit

. Moreover, fuses or

circuit breakers can be used to provide the overcurrent protection in the installation. Overcurrent protection must always be carried out according to

national regulations.

Fuses must be designed for protection in a circuit capable of supplying a maximum of 100,000 A

rms

(symmetrical), 500 V maximum.

Non UL compliance

If UL/cUL is not to be complied with, we recommend using the following fuses, which will ensure compliance with EN50178:

In case of malfunction, not following the recommendation may result in unnecessary damage to the frequency converter.

FC Type

Max. fuse size

1)

Min. rated Voltage Type

K25-K75 10A 200-240 V type gG

1K1-2K2 20A 200-240 V type gG

3K0-3K7 32A 200-240 V type gG

5K5-7K5 63A 200-240 V type gG

11K 80A 200-240 V type gG

15K-18K5 125A 200-240 V type gG

22K 160A 200-240 V type aR

30K 200A 200-240 V type aR

37K 250A 200-240 V type aR

1) Max. fuses - refer to national/international regulations to select an appropriate fuse size.

VLT

®

AutomationDrive FC 300 Operating

Instructions

3 How to Install

MG.33.AG.02 - VLT

®

is a registered Danfoss trademark

29

3

Loading...

Loading...