•

Input the tension reference in parameter

parameter 37-21 Tension Set Point.

•

Set parameter parameter 37-57 Tension On/Off to

[1] On, parameter parameter 37-59 Diameter Reset

to [0] Off, and then initiate a start signal.

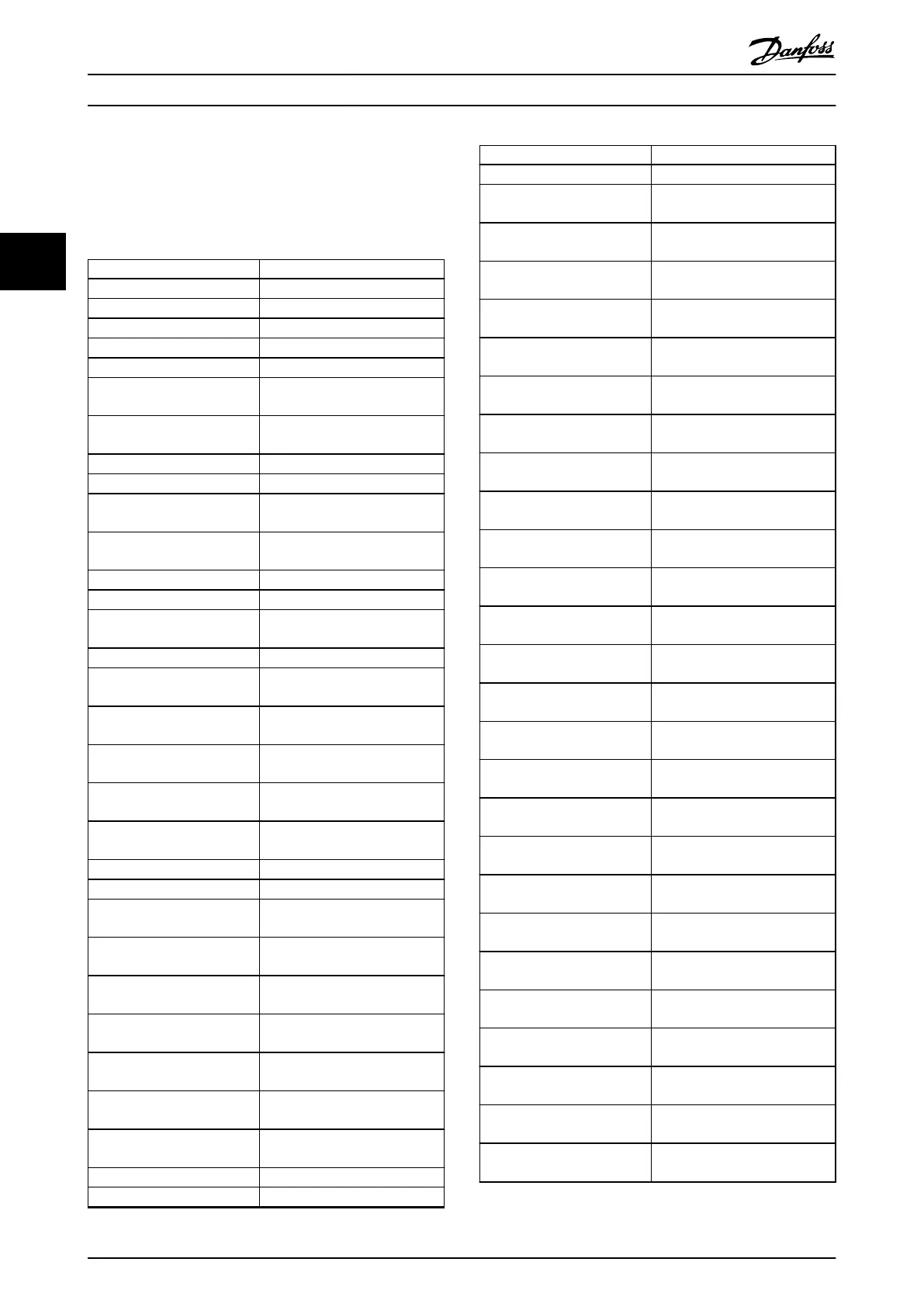

Parameter Value

3-03 Maximum Reference

50

3-41 Ramp 1 Ramp Up Time

0.05

3-42 Ramp 1 Ramp Down Time

0.05

5-30 Terminal 27 Digital Output

[174] TLD indicator

5-31 Terminal 29 Digital Output

[173] End of roll

5-70 Term 32/33 Pulses Per

Revolution

Based on the winder encoder.

5-71 Term 32/33 Encoder

Direction

Based on the winder encoder.

6-10 Terminal 53 Low Voltage

0

6-11 Terminal 53 High Voltage

10

6-14 Terminal 53 Low Ref./

Feedb. Value

0

6-15 Terminal 53 High Ref./

Feedb. Value

100

6-19 Terminal 53 mode

[1] Voltage mode

6-70 Terminal 45 Mode

[2] Digital Output

Parameter 6-72 Terminal 45

Digital Output

[176] Ready to run

6-90 Terminal 42 Mode

[0] 0–20 mA

6-91 Terminal 42 Analog

Output

[162] Tapered tension set point

6-93 Terminal 42 Output Min

Scale

0

6-94 Terminal 42 Output Max

Scale

100

7-00 Speed PID Feedback

Source

[1] 24V encoder

7-07 Speed PID Feedback Gear

Ratio

Based on the application.

17-10 Signal Type

Based on the line encoder.

17-11 Resolution (PPR)

Based on the line encoder.

Parameter 37-00 Application

Mode

[0] Drive mode

Parameter 37-20 Winder Mode

Selection

[0] Wind

Parameter 37-22 Taper Set

Point

0

Parameter 37-23 Partial Roll

Diameter Value

5.000%

Parameter 37-24 Core1

Diameter

Based on the application.

Parameter 37-25 Core2

Diameter

Based on the application.

Parameter 37-26 Winder Jog

Speed

1

Parameter 37-27 TLD Low Limit

0

Parameter 37-28 TLD High Limit

90

Parameter 37-29 TLD Timer

1

Parameter 37-30 TLDOnDelay

1

Parameter 37-31 Diameter Limit

Detector

90

Parameter 37-32 Initial

Diameter Measurement

[0] Set diameter when diameter

reset (default)

Parameter 37-33 Diameter

Measurement Input

[0] No function

Parameter 37-34 Reading at

Core

0.00

Parameter 37-35 Reading at

Full Roll

0.00

Parameter 37-36 Tension Set

Point Input

[0] Par.3721

Parameter 37-37 Taper Set

Point Input

[0] Par.3722

Parameter 37-38 Tension

Feedback Input

[1] Input 53(0–10 V DC or 0–20

mA )

Parameter 37-39 Tension

Feedback Type

Based on the application.

Parameter 37-40 Center Winder

Cmd Src

[1] Parameter 19-61–19-67

control the functions

Parameter 37-41 Diameter

Change Rate

0.02

Parameter 37-42 Tapered

Tension Change Rate

0.2

Parameter 37-43 Diameter

Calculator Min Speed

0.5

Parameter 37-44 Line

Acceleration Feed Forward

0

Parameter 37-45 Line Speed

Source

[2] MCB102

Parameter 37-46 Winder Speed

Match Scale

1.000

Parameter 37-47 Tension PID

Profile

Based on the application.

Parameter 37-48 Tension PID

Proportional Gain

Based on the application.

Parameter 37-49 Tension PID

Derivate Time

Based on the application.

Parameter 37-50 Tension PID

Integral Time

Based on the application.

Parameter 37-51 Tension PID

Out Limit

0.00%

Parameter 37-52 Tension PID

Der Gain Limit

Based on the application.

Parameter 37-53 Tension PID

Anti Windup

[1] Enable

Parameter 37-54 Winder Jog

Reverse

0

Parameter 37-55 Winder Jog

Forward

0

Parameter 37-56 New Diameter

Select

[0] Core Diameter

Center Winder Control

VLT

®

AutomationDrive FC 360

10 Danfoss A/S © 11/2014 All rights reserved. MG06E102

33

Loading...

Loading...