VLT

®

FCM Series

Programming

Example:

Parameter 201: minimum frequency, conversion factor

0,1. If parameter 201 is to be set to 10 Hz, a value of

100 must be transferred, since a conversion factor of

0,1 means that the transferred value will be multiplied

by 0.1. A value of 100 will thus be understood as 10.

A

ddressing by unit ID

The unit ID is printed on the label on the plastic

cover under the lid of the electronics box. The three

groups of unit ID each with three digits must be

converted to Hex. The desired address is added as

the last byte. The frame is sent to the bus address

parameter(s) 500 (and 918) via a broadcast.

PKE: Write to parameter No. 500 or 918

IND: Not Used

2. Process-bytes

The process byte block is divided into two blocks each

of 16 bits, which always come in the sequence stated.

PCD1 PCD2

Control

telegram

(master→slave)

Control word Reference

value

Reply telegram

(slave→master)

Status word Given output

frequency

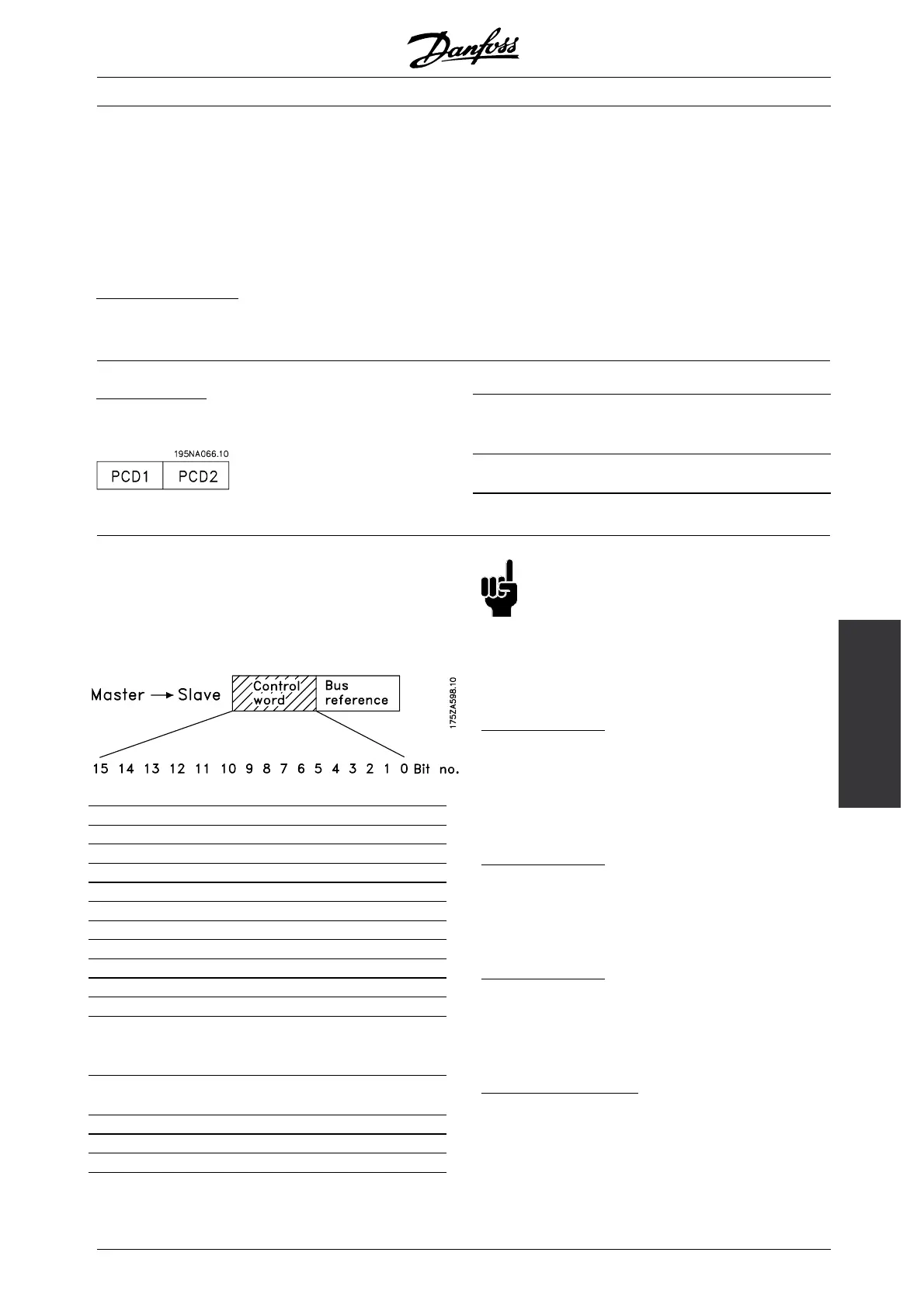

■ Control wordaccording to FieldbusProfile Standard

(parameter 512 = Fieldbus Profile) The control word

is used for transmitting commands from a master

(e.g. a PC) to a slave (FC motor).

Bit Bit = 0 Bit =1

00 OFF 1 ON 1

01 OFF 2 ON 2

02 OFF 3 ON 3

03 Motor coasting Enable

04 Quick-stop Ramp

05 Freeze output frequency Ramp enable

06 Ramp stop Start

07 No function Reset

08 Jog1OFF ON

09 Jog2OFF ON

10 Data not valid Valid

11 No function Slow down /

Relay 123 / Digital

output terminal 9

12 No function Catch-up / Relay

123

13 Setup 1 Setup 2

14

15 No function Reversing

NB!:

The use of Bit 00, Bit 01 and Bit 02 for

switching off the power supply (by use of

relay) will require a separate power on. This

because there is no 24V external connection to supply

the FCM 300 control, which is required to activate

the FCM 300 again via input signal.

B

it 00, OFF1/ON1:

An ordinary ramp stop which uses the ramp time

in parameters 207/208. Bit 00 = "0" leads to

a stop. Bit 00 = "1" means that the frequency

converter will be able to start if the other conditions

for starting have been fulfilled.

B

it 01, OFF2/ON2:

Coasting stop. Bit 01 = "0" leads to a coasting stop.

Bit 01 = "1" means that the frequency converter

is able to start, provided the other conditions

for starting have been fulfilled.

B

it 02, OFF3/ON3:

Quick-stop, which uses the ramp time in parameter 212.

Bit 02 = "0" leads to a quick-stop. Bit 02 = "1" means

that the frequency converter is able to start, provided

the other conditions for starting have been fulfilled.

B

it 03, Coasting/enable:

Coasting. Bit 03 = "0" leads to a stop. Bit 03 =

"1" means that the frequency converter is able to

start, provided the other conditions for starting are

fulfilled. Note: In parameter 502 the choice is made

MG.03.H3.02 - VLT is a registered Danfoss trademark

81

Loading...

Loading...