VLT

®

FCM Series

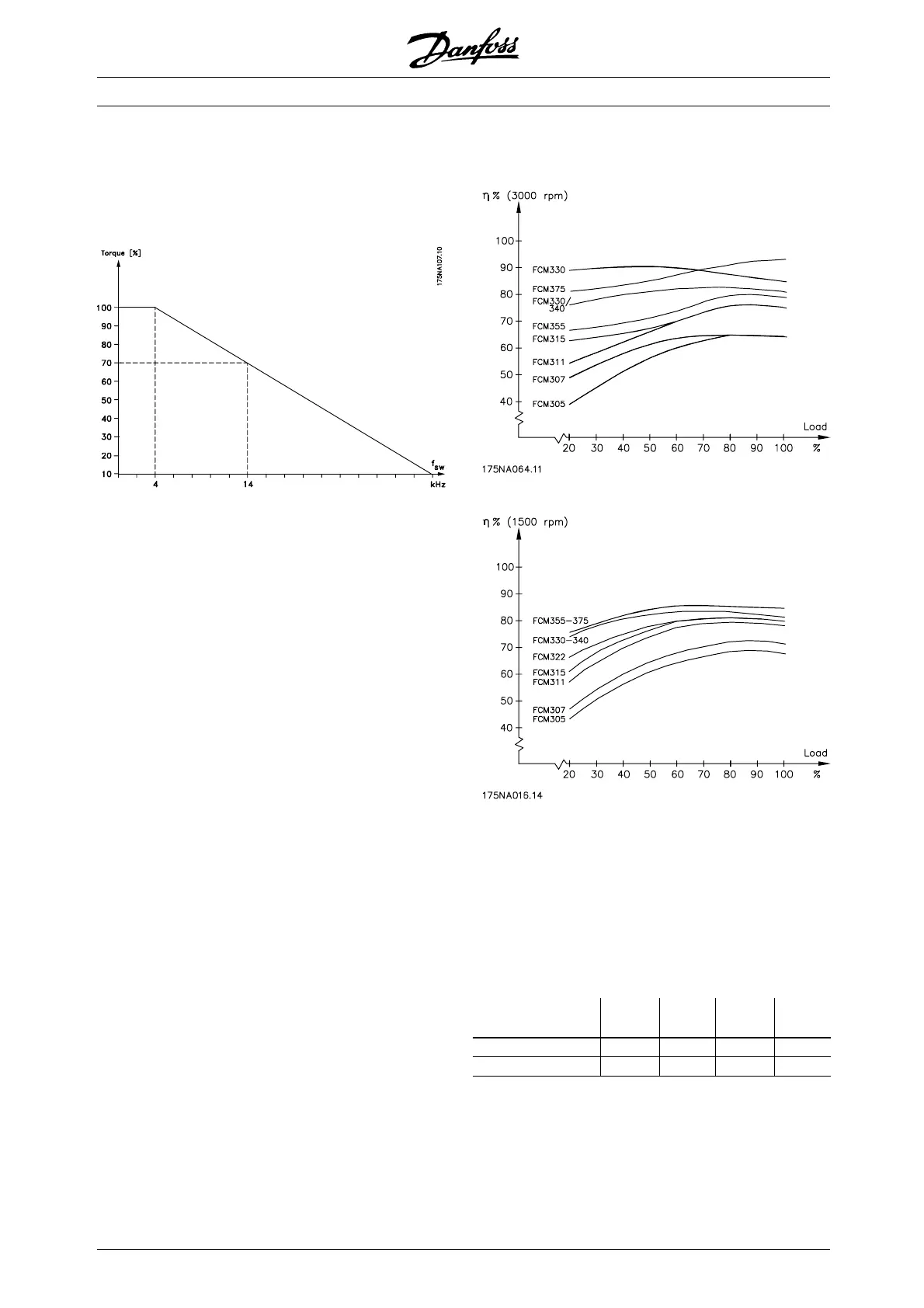

A higher switching frequency leads to a quieter running

unit but higher losses in the electronics of the FC motor

and makes an appropriate derating necessary.

See below Torque carateteristic

■ Vibration and shock

FCM 300 Series has been tested according to a

procedure based on the following standards:

IEC 60068-2-6: Vibration (sinusoidal) - 1970

IEC 60068-2-34: Random vibration broad-band

- general requirements

IEC 60068-2-35: Random vibration broad-band

- high reproducibility

IEC 60068-2-36: Random vibration broad-band

- medium reproducibility

FCM 300 Series complies with requirements

that correspond to conditions in the standards

mentioned above.

■ Air humidity

FCM 300 Series has been designed to meet

the IEC 60068-2-3 standard, EN 50178 item

9.4.2.2/DIN 40040, class E, at 40°C.

Cyclic damp heat according to IEC 60068-2-30, 40°C.

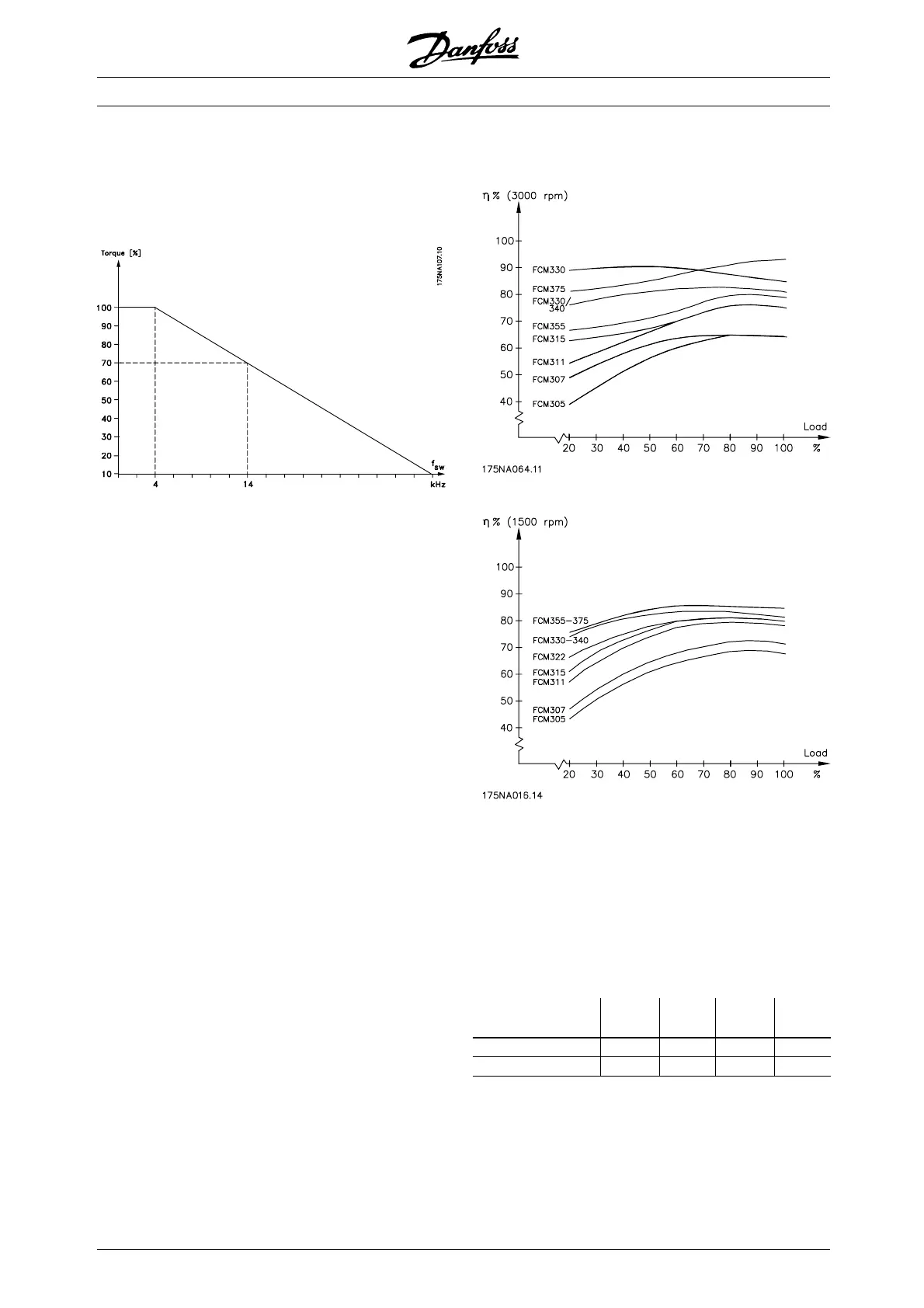

■ Efficiency

2pole

4pole

■ Mains supply interference/harmonics

A FC motor takes up a non-sinusoidal current from

mains, which increases the input current I

RMS

.A

nonsinusoidal current can be transformed by means of

a Fourier analysis and split up into sine wave currents

with different frequencies, i.e. different harmonic

currents I

N

with 50 Hz as the basic frequency:

Harmonic

currents

I

1

I

5

I

7

I

11

Hz 50 Hz 250 Hz 350 Hz 550 Hz

In/I1 [%] 100% 44% 29% 8%

The harmonics do not affect the power consumption

directly, but increase the heat losses in the installation

(transformer, cables). Consequently, in plants

with a rather high percentage of rectifier load, it

is important to maintain harmonic currents at a

low level to avoid overload of the transformer and

high temperature in the cables.

MG.03.H3.02 - VLT is a registered Danfoss trademark

90

Loading...

Loading...