1.3.4 Connecting to Line Power and Motor

The adjustable frequency drive is designed to operate all

standard 3-phased asynchronous motors.

The adjustable frequency drive is designed to accept line

power/motor cables with a maximum cross-section of

4 mm

2

/10 AWG (M1, M2 and M3) and maximum cross-

section 16 mm

2

/6 AWG (M4 and M5).

•

Use a shielded/armored motor cable to comply

with EMC emission specifications, and connect

this cable to both the decoupling plate and the

motor metal.

•

Keep motor cable as short as possible to reduce

the noise level and leakage currents.

•

For further details on mounting of the

decoupling plate, see VLT Micro FC 51 Decoupling

Mounting Plate Instructions.

•

Also see EMC-compatible Installation in the

Design Guide.

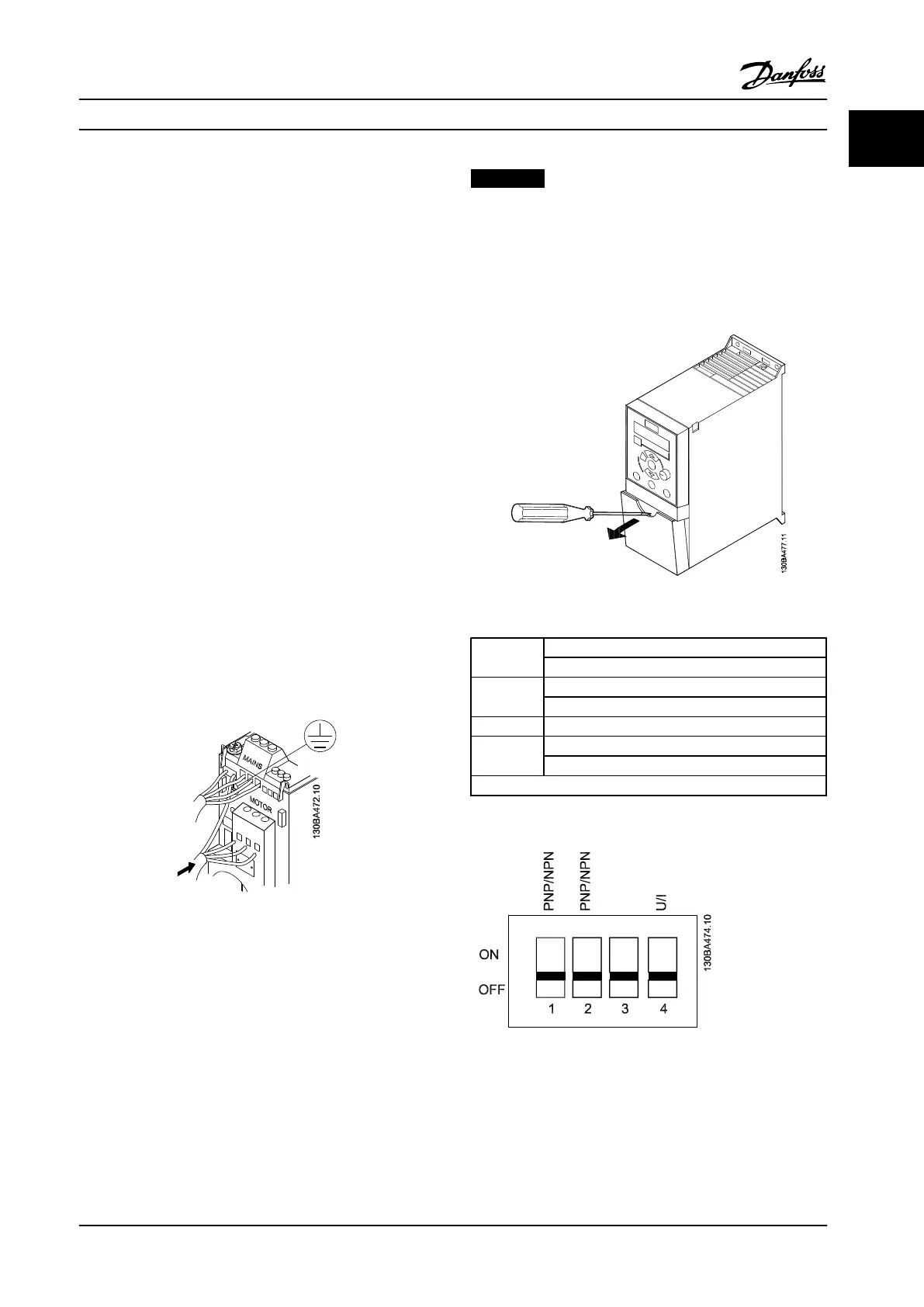

1. Mount the ground wires to PE terminal.

2. Connect the motor to terminals U, V and W.

3. Mount line power supply to terminals L1/L, L2

and

L3/N (3-phase) or L1/L and L3/N (single-phase)

and tighten.

Figure 1.2 Mounting of Ground Cable, Line Power and Motor

Wires

1.3.5

Control Terminals

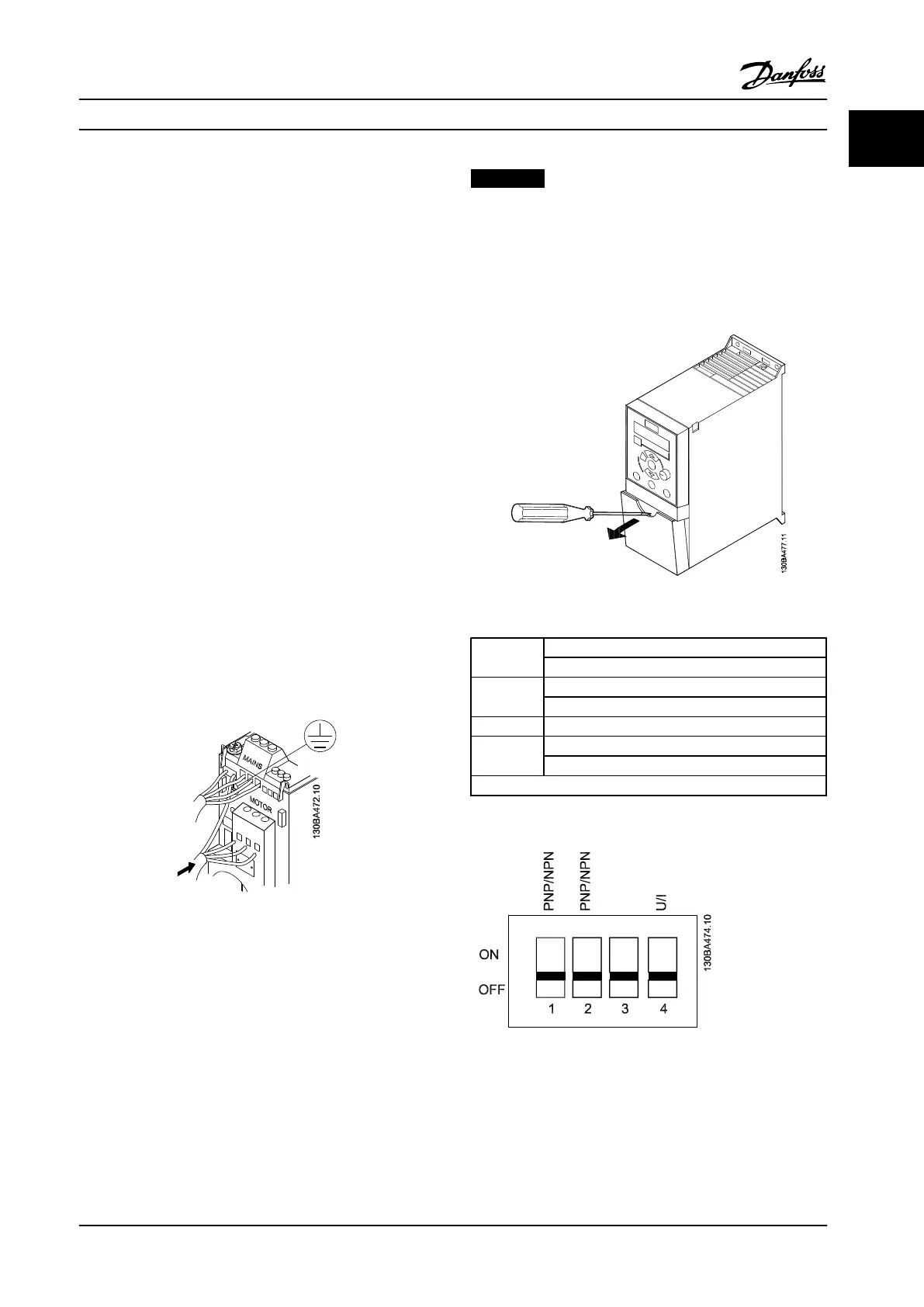

All control cable terminals are located underneath the

terminal cover in front of the adjustable frequency drive.

Remove the terminal cover using a screwdriver.

NOTICE!

See back of terminal cover for outlines of control

terminals and switches.

Do not operate switches with power on the adjustable

frequency drive.

6-19 Terminal 53 Mode must be set according to Switch 4

position.

Figure 1.3 Removing Terminal Cover

Switch 1

*Off=PNP terminals 29

On=NPN terminals 29

Switch 2

*Off=PNP terminal 18, 19, 27 and 33

On=NPN terminal 18, 19, 27 and 33

Switch 3 No function

Switch 4

*Off=Terminal 53 0–10 V

On=Terminal 53 0/4–20 mA

*=default setting

Table 1.5 Settings for S200 Switches 1-4

Figure 1.4 S200 Switches 1-4

Quick Guide Quick Guide

MG02B922 Danfoss A/S © Rev. 2014-02-27 All rights reserved. 7

1

1

Loading...

Loading...