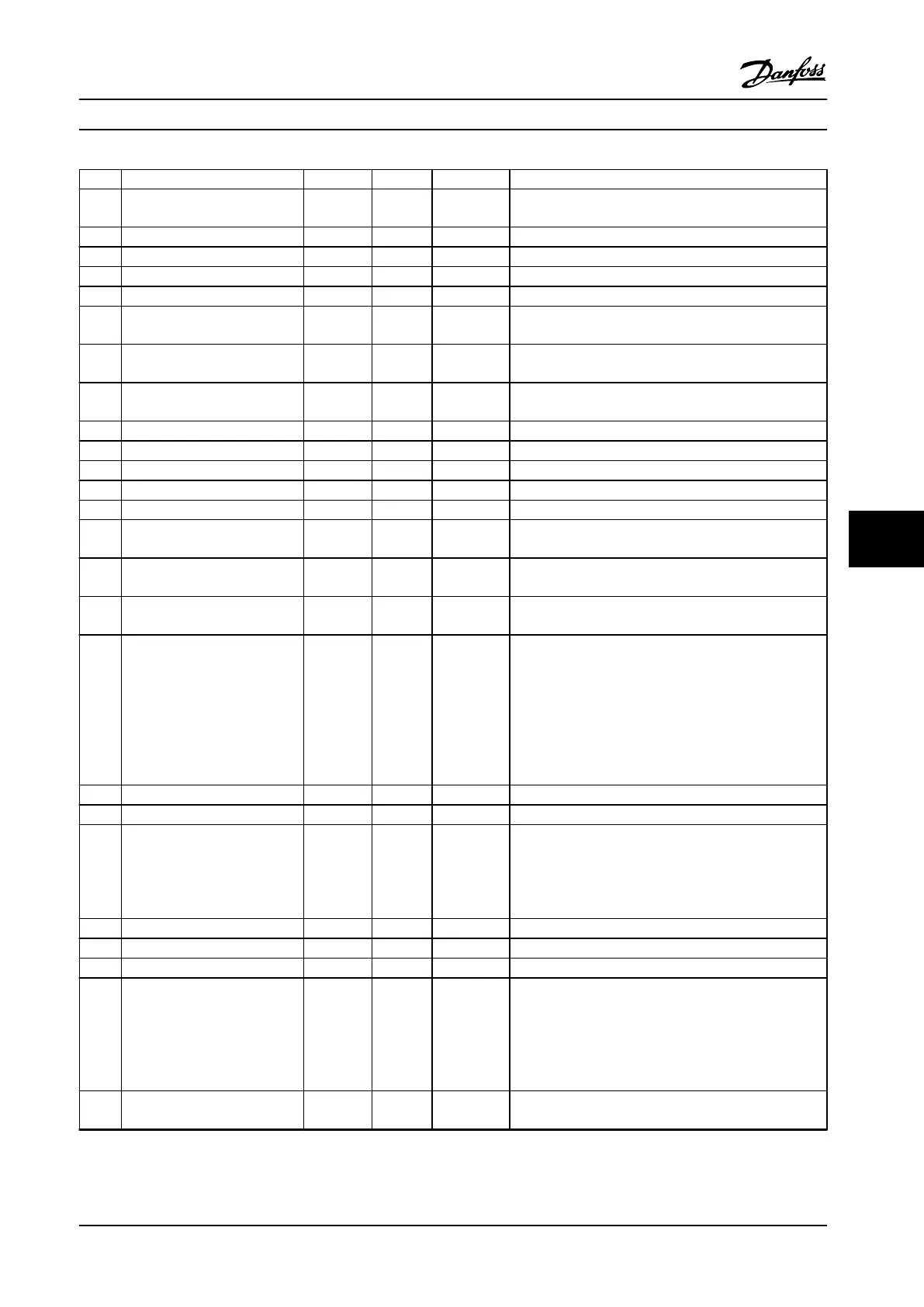

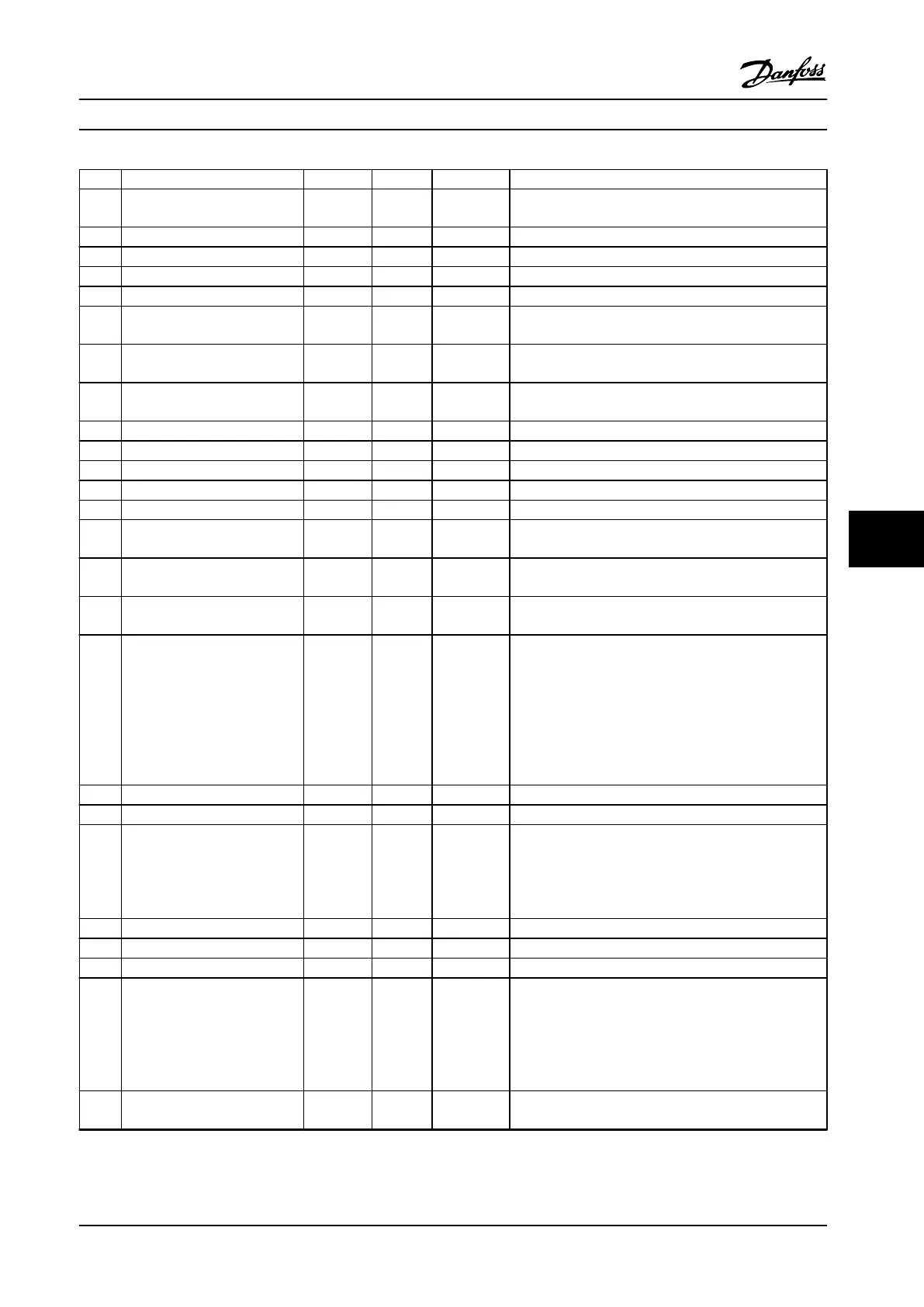

No. Description Warning Alarm Trip lock Cause

41 Overload T29 – – –

Check the load connected to terminal 29 or remove short

circuit connection.

46 Gate drive voltage fault X X

47 24 V supply low X X X 24 V DC may be overloaded.

51 AMA check U

nom

and I

nom

– X – Wrong setting for motor voltage and/or motor current.

52 AMA low I

nom

– X – Motor current is too low. Check the settings.

53 AMA big motor

– X –

The power size of the motor is too large for the AMA to

operate.

54 AMA small motor

– X –

The power size of the motor is too small for the AMA to

operate.

55 AMA parameter range – X –

The parameter values of the motor are outside of the

acceptable range. AMA does not run.

56 AMA interrupt – X – The AMA is interrupted.

57 AMA timeout – X –

58 AMA internal – X – Contact Danfoss.

59 Current limit X X – Adjustable frequency drive overload.

61 Encoder loss X X –

63 Mechanical brake low – X –

Actual motor current has not exceeded release brake

current within start delay time window.

65 Control card temp

X X X

The cut-out temperature of the control card is 80 °C

(176 °F).

67 Option change

– X –

A new option is detected or a mounted option is

removed.

68 Safe Stop

X X –

STO is activated. If STO is in manual restart mode

(default), to resume normal operation, apply 24 V DC to

terminals 37 and 38 and initiate a reset signal (via serial

communication bus, digital I/O or [Reset]/[O Reset] key).

If STO is in automatic restart mode, applying 24 V DC to

terminals 37 an 38 automatically resumes the adjustable

frequency drive to normal operation. Refer to

chapter 6.3 STO Commissioning for more details.

69 Power card temp X X X

80 Drive initialized to default value X All parameter settings are initialized to default settings.

87 Auto DC braking X – –

Occurs in IT line power when the adjustable frequency

drive coasts and the DC voltage is higher than 830 V for

400 V units, and 425 V for 200 V units. Energy on DC link

is consumed by the motor. This function can be enabled/

disabled in parameter 0-07 Auto DC Braking.

88 Option detection – X X The option is removed successfully.

95 Broken belt X X –

120 Position control fault – X –

188 STO internal fault

– X –

24 V DC supply is connected to only one of the 2 STO

terminals (37 and 38), or a failure in STO channels is

detected. Make sure that both terminals are connected to

24 V DC supply, and the discrepancy between the signals

at the two terminals is less than 12 ms. If the fault still

occurs, contact the local Danfoss supplier.

nw

run

Not while running – – –

Parameter can only be changed when the motor is

stopped.

Maintenance, Diagnostics an... Instruction Manual

MG07A122 Danfoss A/S © 11/2015 All rights reserved. 45

8 8

Loading...

Loading...