10

ADJUSTING SPINDLE

ASSEMBLY

If excessive play develops in the spindle assembly, or if

noise level increases after extended use, make the fol-

lowing adjustment to the spindle assembly.

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. Turn the machine over and place it on a firm

supporting surface. Be careful not to damage the

spindle assembly.

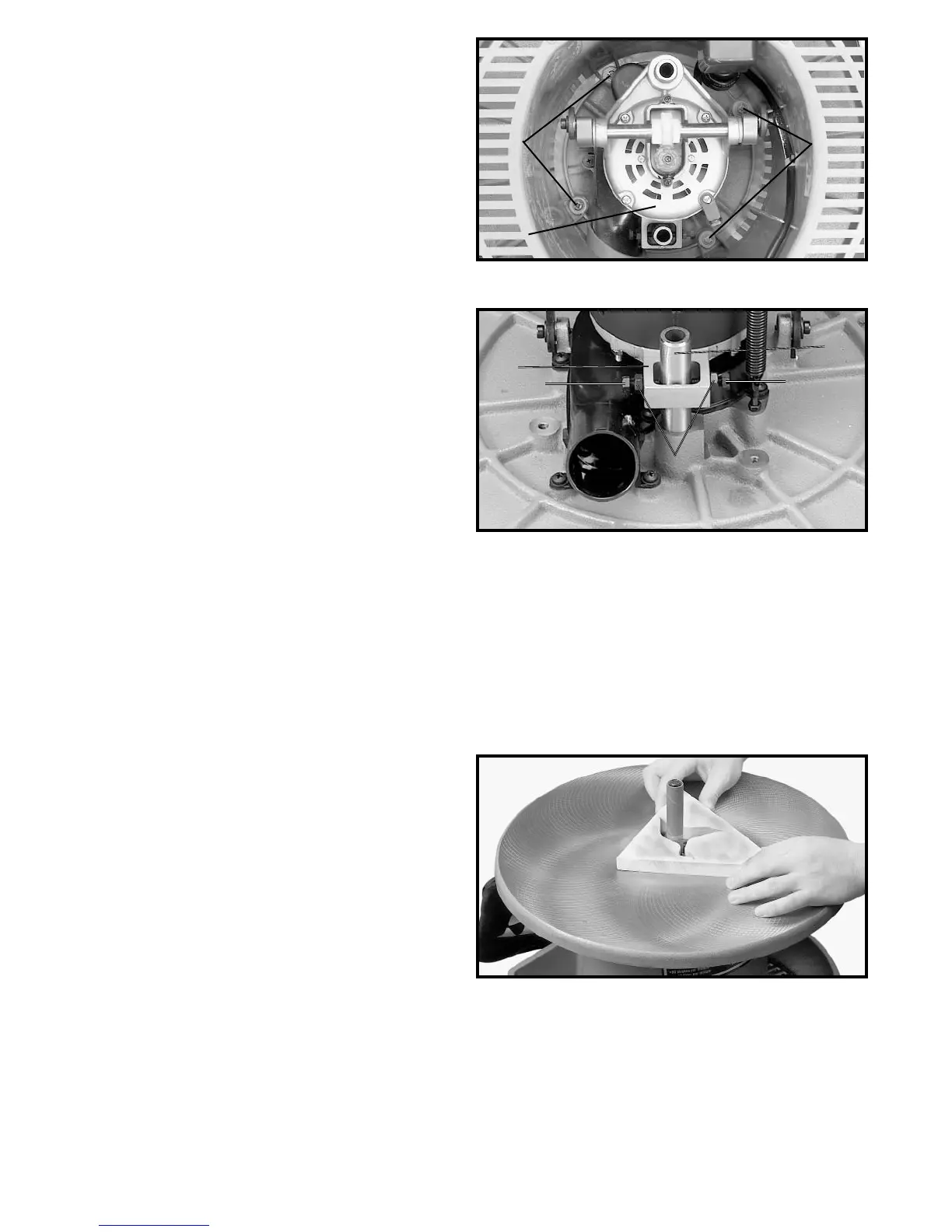

3. Remove the four mounting screws (A) Fig. 22 and

remove the case (B) from the machine.

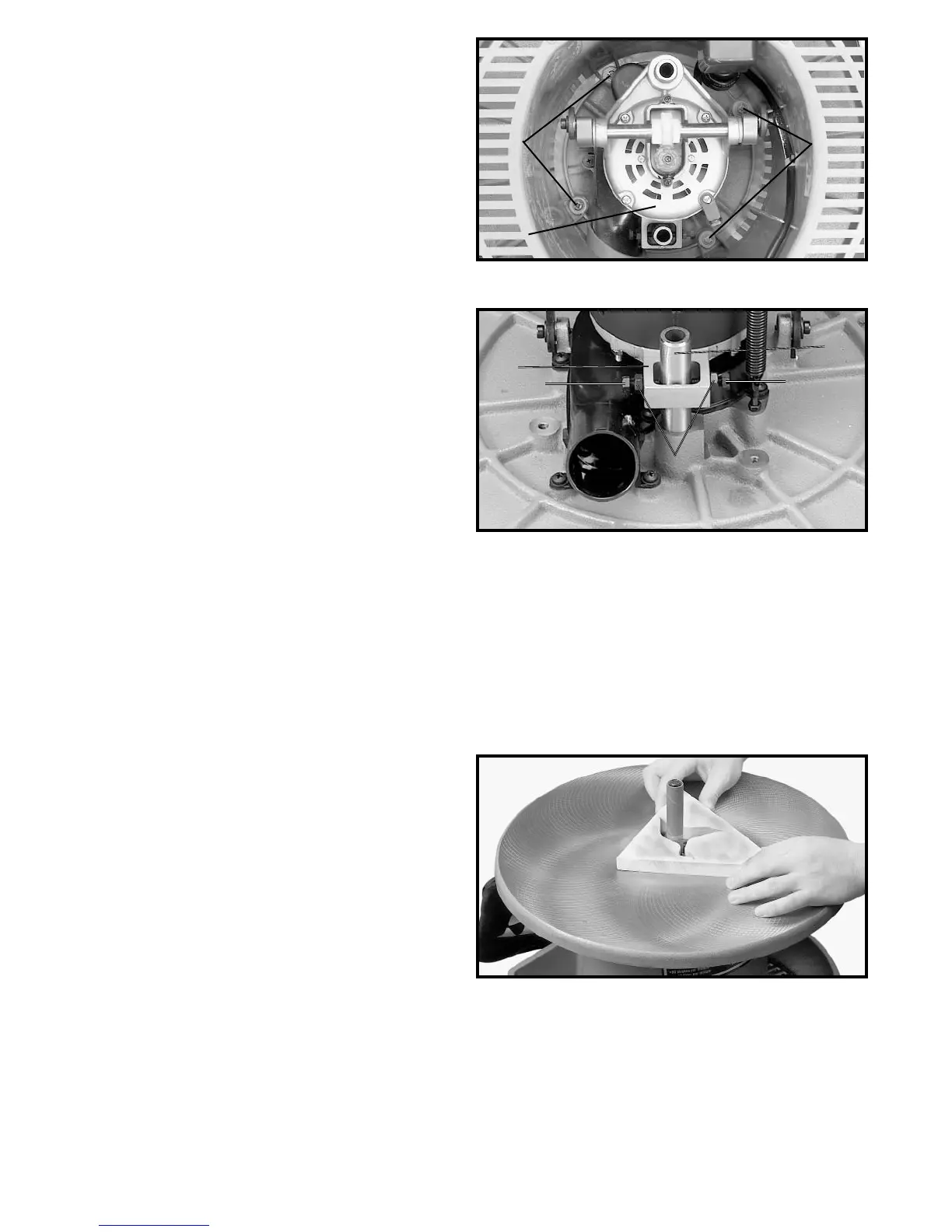

4. IMPORTANT: Shaft (C) Fig. 23, must be positioned

inside the center of bracket (D). To adjust, loosen the

two locknuts (E) Fig. 23. Tighten or loosen the two

adjusting screws (F) as necessary until the shaft (C) is

centered inside the bracket (D), with the adjustment

screws (F) contacting the shaft. Tighten the two locknuts

(E) Fig. 23.

5. Attach the case with the four screws removed in

STEP 3.

Fig. 22

A

A

Fig. 23

B

E

F

F

C

D

OPERATION

Fig. 24, illustrates sanding inside curves.

IMPORTANT: Always sand against the rotation of the

sanding drum.

The oscillating action of the sanding drum minimizes

score marks and prevents clogging of the sanding drum,

providing faster, smoother sanding and increasing the

life of the sanding sleeve.

Fig. 24

Loading...

Loading...