ENGLISH

21

will cause a drop in line voltage resulting in loss of power

and overheating. When using more than one extension

to make up the total length, be sure each individual

extension contains at least the minimum wire size. The

following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The lower the gauge number, the

heavier thecord.

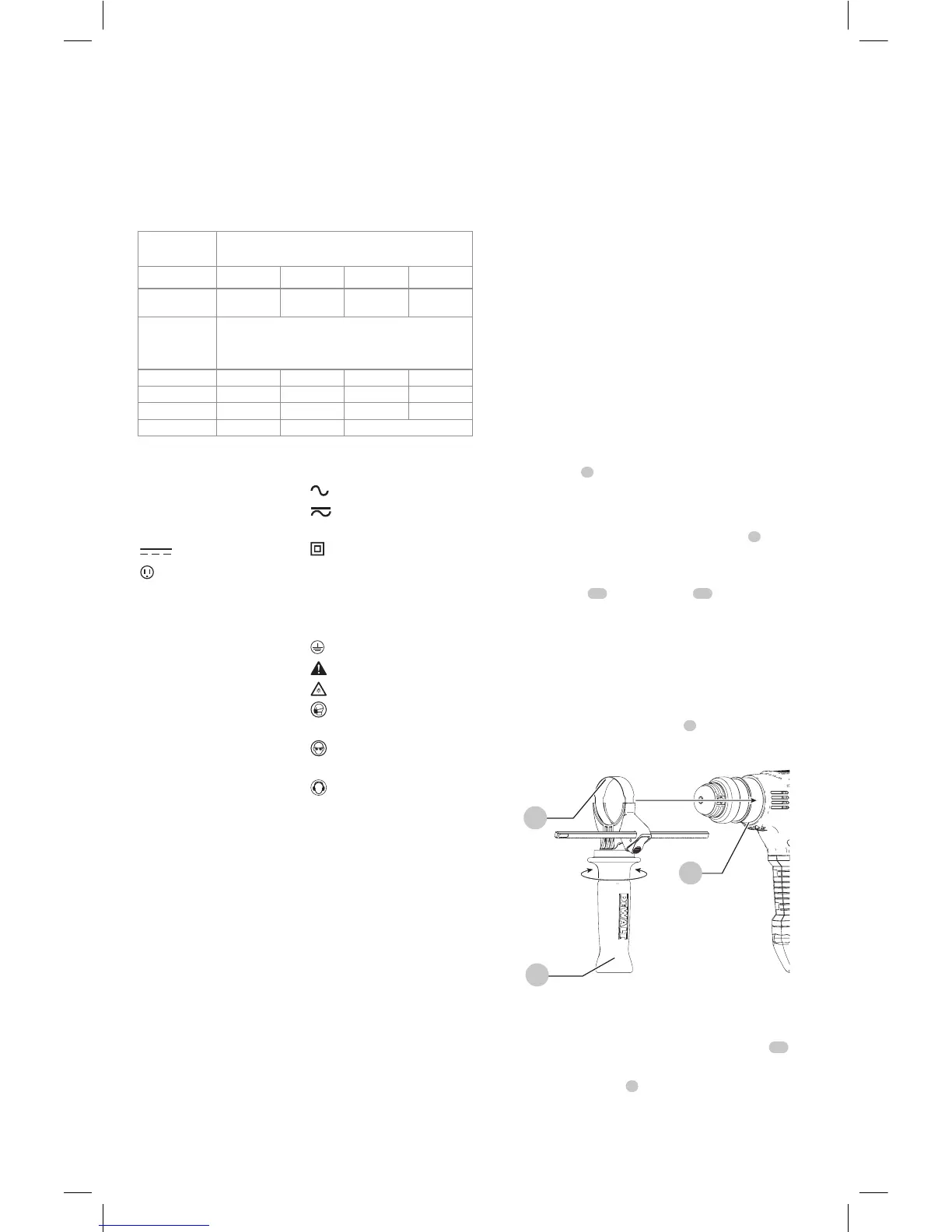

Voltage

(Volts)

Total length of cord in meters (m)

120–127V 0–7 7–15 15–30 30–50

220–240V 0–15 15–30 30–60 60–100

Rated

Ampere

Range

Minimal cross-sectional area of the

cord in meters (mm

2

)

0–6A 1.0 1.5 1.5 2.5

6–10A 1.0 1.5 2.5 4.0

10–12A 1.5 1.5 2.5 4.0

12–16A 2.5 4.0 Not Recommended

The label on your tool may include the following symbols. The

symbols and their definitions are asfollows:

V ......................... volts

Hz .......................hertz

min ..................... minutes

or DC ......direct current

...................... Class I Construction

(grounded)

…/min ..............per minute

BPM ....................beats per minute

IPM ..................... impacts per minute

RPM .................... revolutions per

minute

sfpm ................... surface feet per

minute

SPM .................... strokes per minute

A ......................... amperes

W ........................watts

or AC ...........alternating current

or AC/DC .... alternating or

direct current

...................... Class II

Construction

(double insulated)

n

o

........................no load speed

n .........................rated speed

......................earthing terminal

.....................safety alert symbol

.....................visible radiation

..................... wear respiratory

protection

..................... wear eye

protection

..................... wear hearing

protection

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Motor

Be sure your power supply agrees with the nameplate

marking. Voltage decrease of more than 10% will cause loss

of power and overheating.

tools are factory tested;

if this tool does not operate, check powersupply.

COMPONENTS (FIG. A)

WARNING: Never modify the power tool or any part

of it. Damage or personal injury couldresult.

Refer to Figure A at the beginning of this manual for a

complete list ofcomponents.

INTENDED USE

Your heavy-duty rotary hammers is designed for

professional concrete drilling and chiselingapplications.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

Your heavy-duty rotary hammer is a professional power

tools. DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

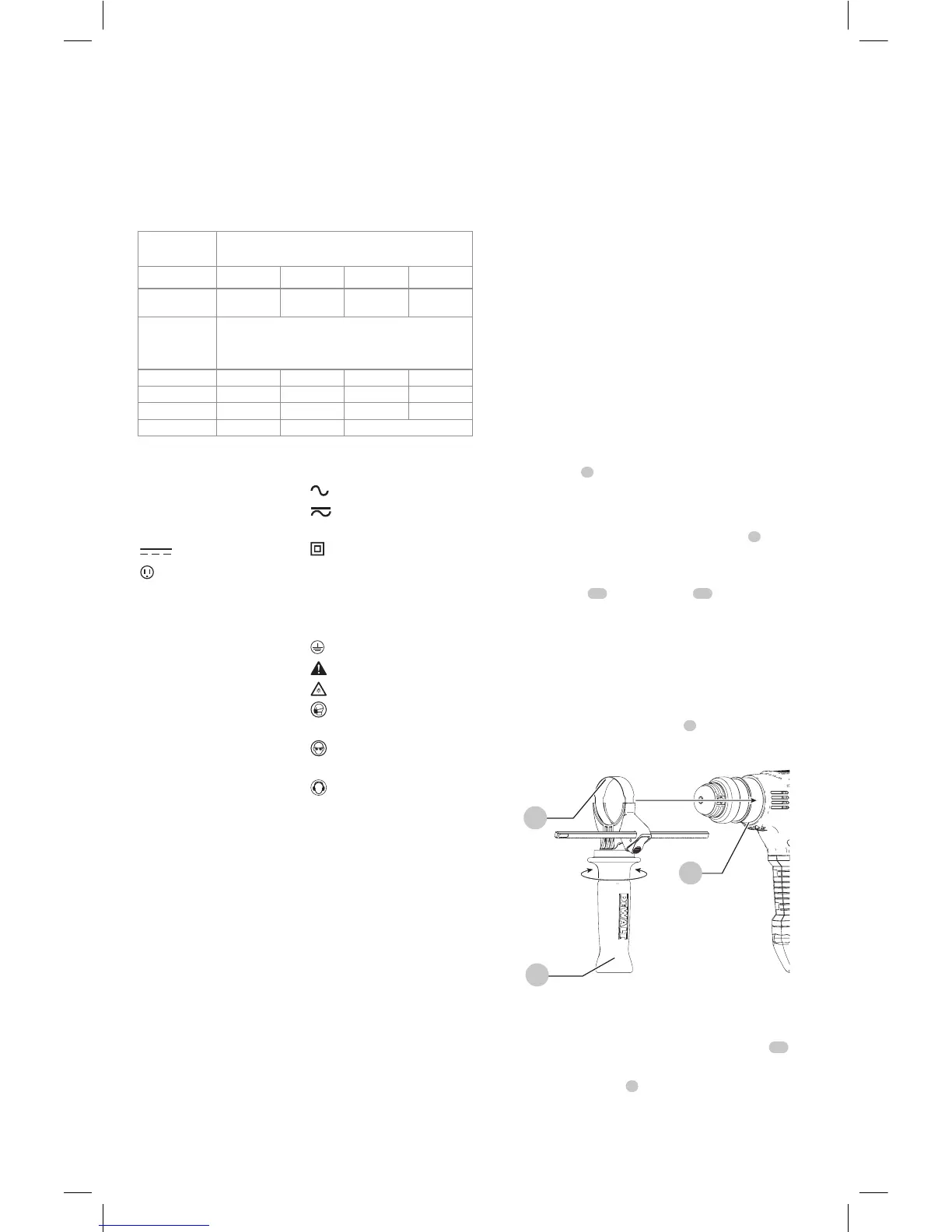

Side Handle and Depth Rod (Fig. B, C)

WARNING: To reduce the risk of personal injury,

ALWAYS operate the tool with the side handle

properly installed. Failure to do so may result in

the side handle slipping during tool operation and

subsequent loss of control. Hold tool with both hands

to maximizecontrol.

The side handle

5

clamps to the front of the gear case and

may be rotated 360˚ to permit right- or left-hand use.

Mounting the Straight Side Handle (Fig.B)

1. Widen the ring opening of the side handle

5

by

rotating it counterclockwise.

2. Slide the assembly onto the nose of the tool, placing

the steel ring

12

onto the collar

11

, past the bit holder

andsleeve.

3. Rotate the side handle assembly to the desired position.

For hammerdrilling horizontally with a heavy drill

bit, place the side handle assembly at an angle of

approximately 20° to the tool for optimumcontrol.

4. Lock the side handle mounting assembly in place by

securely tightening the handle

5

rotating it clockwise

so that the assembly will notrotate.

Fig. B

11

5

12

To Adjust the Depth Rod (Fig. C)

1. Push in and hold the depth rod release button

10

on

the sidehandle.

2. Move the depth rod

9

so the distance between the

end of the rod and the end of the bit equals the desired

drillingdepth.

Loading...

Loading...