ENGLISH

4

Fittings

Install a male fitting on the tool which is free flowing

and which will release air pressure from the tool when

disconnected from the supplysource.

Hoses

Air hoses should have a minimum of 150 p.s.i.g.

(10.6kg/cm²) working pressure rating or 150 percent of

the maximum pressure that could be produced in the air

system. The supply hose should contain a fitting that will

provide “quick disconnecting” from the male fitting

4

on

thetool.

Supply Source

Use only clean regulated compressed air as a power source

for this tool. NEVER USE OXYGEN, COMBUSTIBLE GASES, OR

BOTTLED GASES, AS A POWER SOURCE FOR THIS TOOL AS

TOOL MAYEXPLODE.

Regulator

A pressure regulator with an operating pressure of

0–125p.s.i.g. (0–8.79 kg/cm²) is required to control the

operat iing pressure for safe operation of this tool. Do not

connect this tool to air pressure which can potentially

exceed 200 p.s.i.g. (14 kg/cm²) as tool may fracture or burst,

possibly causinginjury.

Operating Pressure

Do not exceed recommended maximum operating pressure

as tool wear will be greatly increased. The air supply must

be capable of maintaining the operating pressure at the

tool. Pressure drops in the air supply can reduce the tool’s

driving power. Refer to Tool Specifications for setting the

correct operating pressure for thetool.

Filter

Dirt and water in the air supply are major causes of

wear in pneumatic tools. A filter will help to get the best

performance and minimum wear from the tool. The

filter must have adequate flow capacity for the specific

installation. The filter has to be kept clean to be effective

in providing clean compressed air to the tool. Consult the

manufacturer’s instructions on proper maintenance of your

filter. A dirty and clogged filter will cause a pressure drop

which will reduce the tool’sperformance.

Oil Free Motor

The nailer is designed to be used without the need to add

any air tool oil and still deliver long life. If air tool oil is added

tool it will still functionproperly.

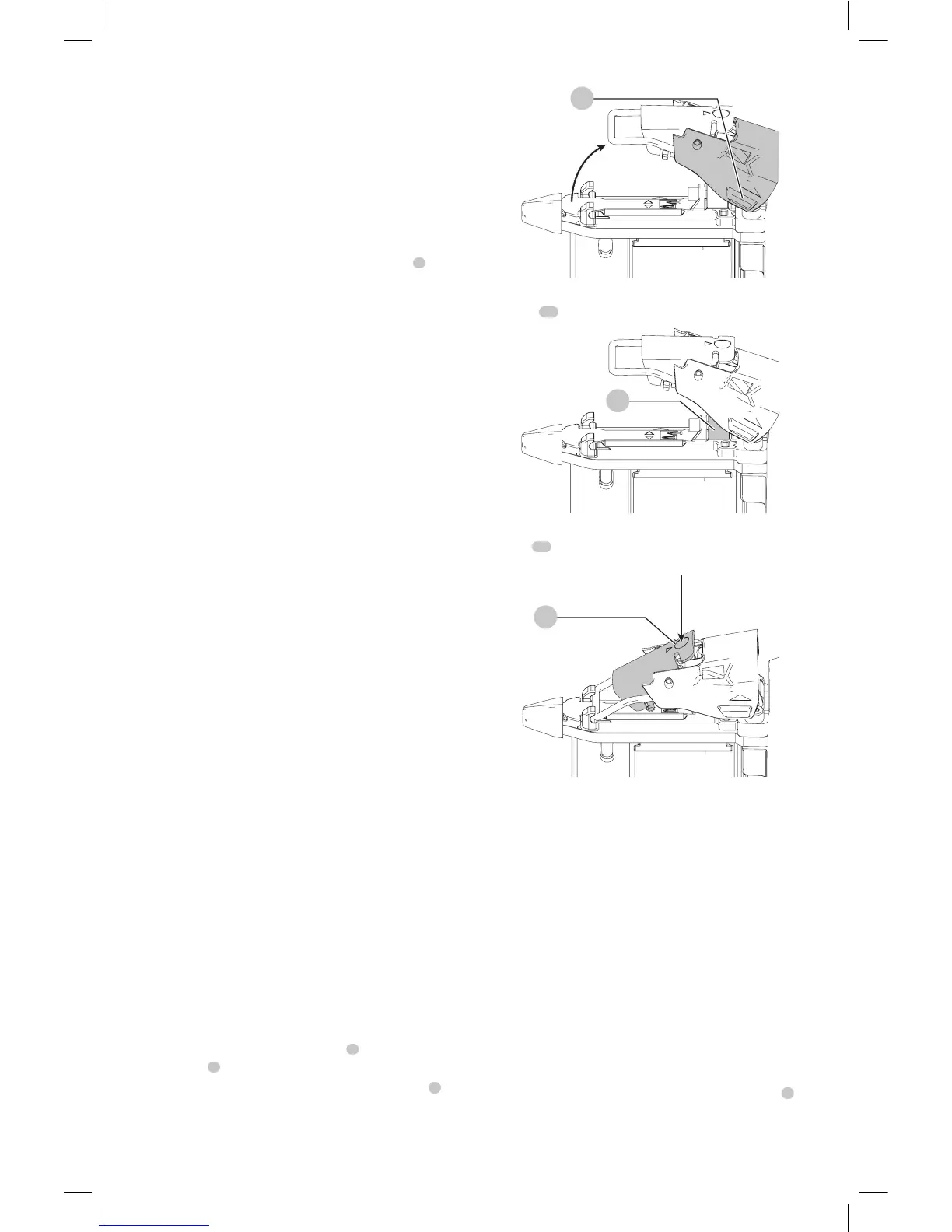

Tool-Free Depth Adjustment (Fig. A, B–D)

You pin nailer features tool-free depth adjustment for

adjusting the driving depth ofpins.

To Adjust the Depth

1. Disconnect the air supply from tool.

2. Depress the magazine release lever

5

and pull the

magazine

6

back to stop pinfeeding.

3. Grab the small tabs on each side of the nose cover

8

and pullup.

Fig. B

8

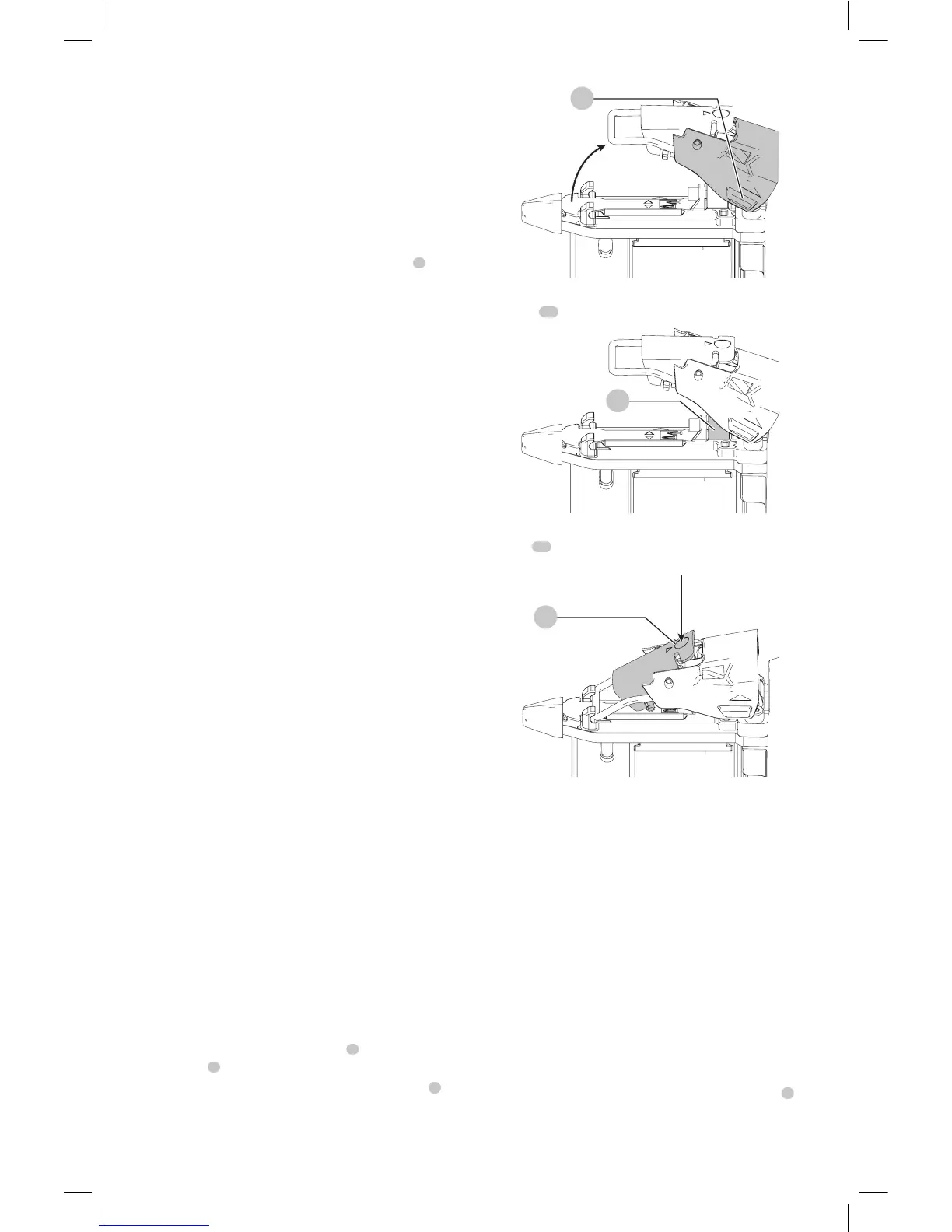

4. With the nose cover lifted, turn the depth adjustment

wheel

10

to adjust thedepth.

Fig. C

10

5. After adjusting to the desired depth, push the pinch

lever

11

down to lock the mechanism back to

operating position .

Fig. D

11

6. Close the magazine and reconnect the airsupply.

Low Pin Lock Out

The nailer is equipped with a low pin lock out which

prevents the tool from actuating when the magazine is

nearly empty. When approximately 10 to 12 pins remain in

the magazine, the tool ceases to operate. Refer to Loading

the Tool to reload a stick of collatedpins.

OPERATION

Proper Hand Position (Fig. E)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the handle

1

.

Loading...

Loading...