(b)

12

Volts d.c.

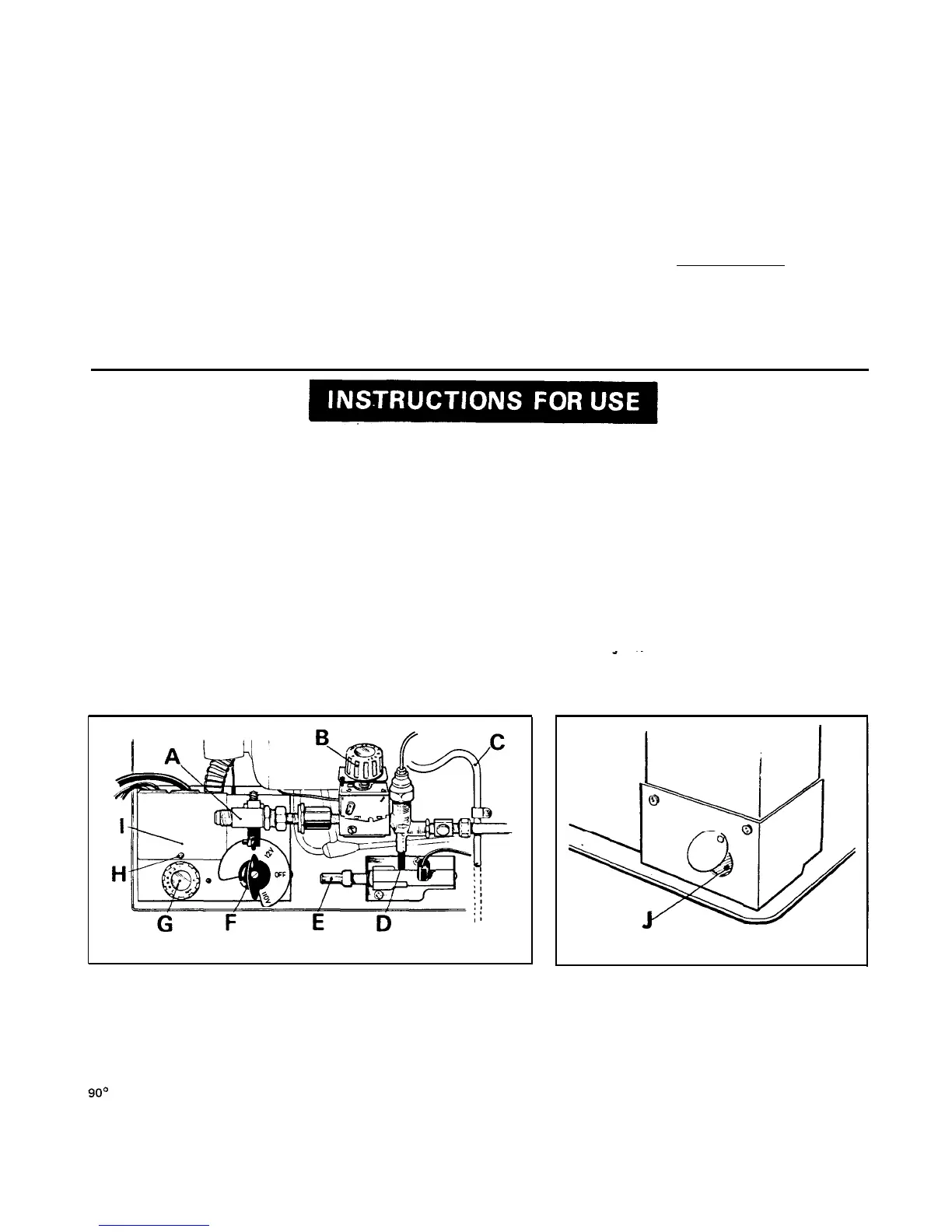

At the back of the refrigerator, at the lower left-hand corner, is the

electric equipment control box (1, fig. 4). Take off the cover from the

box by removing the screw

(H),

and the terminal block will be

visible.

The two terminals at the left-hand end of the terminal block are

the 12 volt supply connections. From these, the refrigerator must be

connected to the main battery in the vehicle by means of two wires,

passing through the entry opening (temporarily sealed with a

dust-

cap)

in the top of the box. Polarity is not important, but the body or

chassis of the automobile or trailer should not be

used

as a substitute

for one of the wires.

The current is 8 amps when the refrigerator is operating on 12 volts

therefore the wiring from the battery to the refrigerator must be

heavy enough to carry this load satisfactorily without voltage drop.

The minimum size of wiring to be used is 14 A.W.G.

The connections to the battery should be made using ring type

clamps with tightening bolts to ensure good contact with the battery

poles.

To prevent the refrigerator operating and draining the battery

when the engine is switched off, it is recommended that an automatic

cut-out relay is installed between the battery and the refrigerator so

that the refrigerator will not draw current from the battery when the

ignition is switched off.

Do not connect lights or any other electrical components to the

wiring from the battery to the refrigerator.

(c)

Fuse

Inside the control box (1, fig.4). in an insulated holder. is a 10 amp

fuse, which is to protect the 12 volt circuit in the event of a short.

If the fuse burns out, trace the cause and correct it before fitting a

similar type 10 amp fuse and reconnecting.

8. DEFROST WATER DRAIN PIPE

The metal pipe

(C,

fig.4) at the back’of the refrigerator is for defrost

water disposal. When installing, connect a suitable length of rubber or

plastic tubing to this pipe, passing the free end through the floor to the

outside of the trailer. The tubing must slope downwards all the way and

must not be pinched or kinked.

9. TESTING AND STARTING UP

When the installation is complete, check all gas connections and fittings

on the refrigerator for tightness in case they have loosened during ship

ping. After lighting the burner

(see

item 11). all gas connections

should-be checked for leaks by applying a soap/water solution over

them and watching for bubbles. Do not use a flame. Thereafter, all

connections should be checked at least once a month. The refrigerator

gas equipment must not be subjected to an internal pressure exceeding

22 inches of water column.

See that the trailer is level in both directions then check that the

ice-tray shelf in the top of the frozen food storage compartment is also

level, from side to side and from front to back, by means of a small

bubble level placed on the ice-tray shelf. This is important for satis-

factory operation of the cooling unit.

10. LEVELING

In the boiler of the cooling unit, ammonia vapor is distilled from an

ammoniawater mixture and carried to the finned condenser where it

liquifies.

The liquid flows to the evaporator inside the cabinet where it

creates cold by evaporating into a circulating flow of hydrogen gas. If

the evaporator is not level, the liquid may accumulate forming pockets

which can impair the gas circulation, or block it completely, in which

case cooling will stop.

When the trailer is stationary for a period, it must be level so that

the refrigerator can operate properly. When the trailer is being parked,

therefore, the level should be checked, preferably by means of a small

bubble level placed on the ice-tray shelf, and the position of the bubble

observed. If necessary, the level of the trailer should then be adjusted

so that the

icetray

shelf is level from side to side, and from front to

back.

When the trailer is on tow, the continuous rolling and pitching

movement will not normally affect the operation of the refrigerator,

but when the trailer is parked for more than a short period, the sensi-

tivity of the refrigerator should be remembered.

(iii)

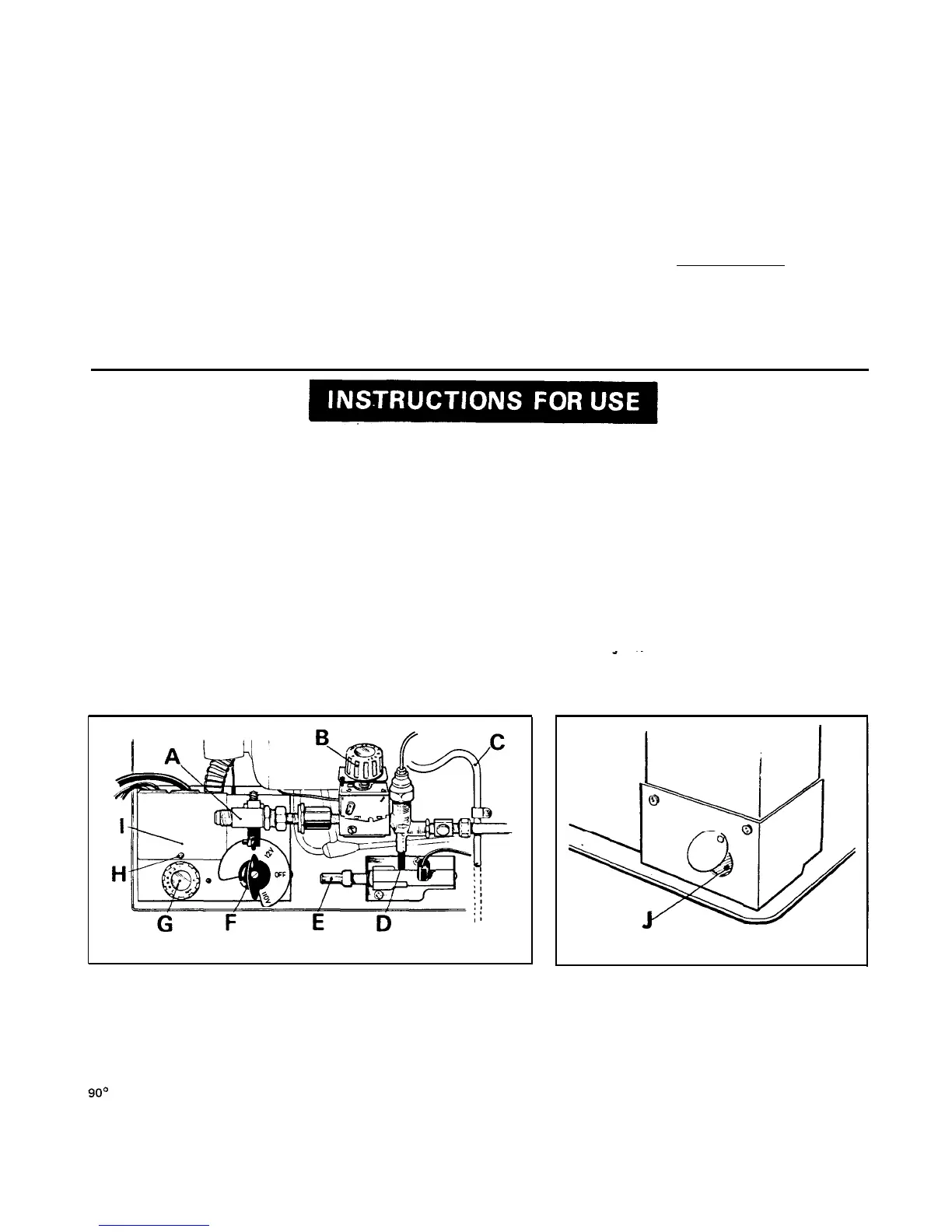

Push in the blue plunger (D) of the flame failure device for 10

to 15 seconds to clear air from fhe pipe-line.

(When

starting

initially, or after changing a gas bottle, it may be necessary to

depress the plunger for a minute or longer to clear all the air

from the pipes). Still pressing in the plunger (D), push in the

button

(E)

of the piezo igniter. The burner should light, but

continue to press in the plunger (D) for a further 15 seconds

then release it end check that the burner is alight by looking at

the flame through the

opening

(J).

If the burner has not lit.

repeat the lighting procedure:

The ice-tray shelf should show signs of cooling after about an

hour.

Note: If the gas has to be re-lit when the ice-making compart-

ment is still cold, the thermostat dial (B) must first be

turned to MAX and returned to its normal setting only

after the burner is alight.

The

refrigerator

has a flame failure device which will

FIG. 4

11. STARTING THE REFRIGERATOR

The gas and electric controls are located at the rear of the refrigerator

and are accessible through the lower ventilator in the wall of the

vehicle. The gas shutoff valve and the electric voltage-change switch

are interlocked so that both methods of operation cannot be inad-

vertently

used

at the same time.

The lower ventilator is removed by turning the handle of its catch

90’

counter-clockwise, then pulling it out.

(a)

L.P.

Gas

Operation

-

Lighting the burner (See figs. 4

&

5)

(i) Check that the voltage change switch

(F)

is at the ‘off’ position,

then turn on the gas valve (A).

(ii)

Turn the gas thermostat knob

(B)

to setting No. 4.

automatically shut off the gas to the burner if the flame is

blown out. While the blue plunger

(D)

is being held in,

this device is temporarily inoperative.

FIG. 5

(b)

Electric Operation

-

(See

fig.4)

The refrigerator can be operated on 12 volts d.c. or 110 volts

a.c.

provided the voltagechange switch (F) is set at the appro-

priate position.

To start the refrigerator on electric operation:-

(i)

Turn off the gas valve

(A),

-

its handle will then be pointing

away from the back of the cabinet.

(ii)

Turn the voltage change switch (F) to the required setting, then

connect the refrigerator to the appropriate voltage supply.

When the electrical supply cord is connected to a

1

10 volt

a.c.

supply. the voltage on the switch

(F)

should show

110V;

when

connected to the battery, the voltage on the switch

(F)

should

show 12V.

(iii) Turn the electric thermostat knob

(G)

to No. 4. The ice-tray

shelf should show signs of cooling after about an hour.

4

Loading...

Loading...