(c)

Flame blows

out

If trouble is encountered with the flame blowing out under specially

windy conditions, try to place the vehicle so that the wind does not

blow directly into the vent outlets. If the trouble persists, set the gas

thermostat to ‘MAX’. This can of course, only be a temporary

measure as after a time at this setting, the foodstuffs in the cabinet

may become too cold.

(d)

Cleaning

Flue. Burner and Jet (See fia.

6)

1.

2.

3.

4.

5.

Once

or

twice a year, depending on-use, examine the appearance of

the flame which should be predominantly blue when the gas

thermostat

is set

at MAX. If this is not the case, the flue, burner, and

jet should be cleaned, as follows.

Take off flue top, then lift out flue baffle on its support wire

which will then be visible.

6.

7.

8.

9.

Remove burner shield which is held to bottom of boiler casing by

two screws.

Disconnect and remove gas pipe

(3)

from between flame failure

device and burner.

Pull out burner jet

(4)

and clean it by washing in alcohol or

blowing through with air. DO NOT USE A PROBE.

Disconnect end of thermocouple (2) from flame failure device by

unscrewing union

(1

).

Leave other end of thermocouple secured to

burner bracket.

Remove burner bracket with burner and thermocouple attached,

by undoing screw

(5)

holding it to bottom of boiler.

Clean burner, making

sure

its gauze head and aeration ports are clear.

Clean flue tube, preferably by means of a special brush available from

your supplier.

Refit all parts, ensuring the burner bracket is properly retained, but

do not overtighten the thermocouple union when connecting it.

Gas connections should be tight but not overtightened,

After re-installing, check all gas joints for soundness as described in

the next item.

(e)

Checking for Gas Leaks

Periodically, the entire gas installation should be checked for leaks.

Test all pipe connections with soapy water (not with a flame),

watching for bubbles, -see item 9.

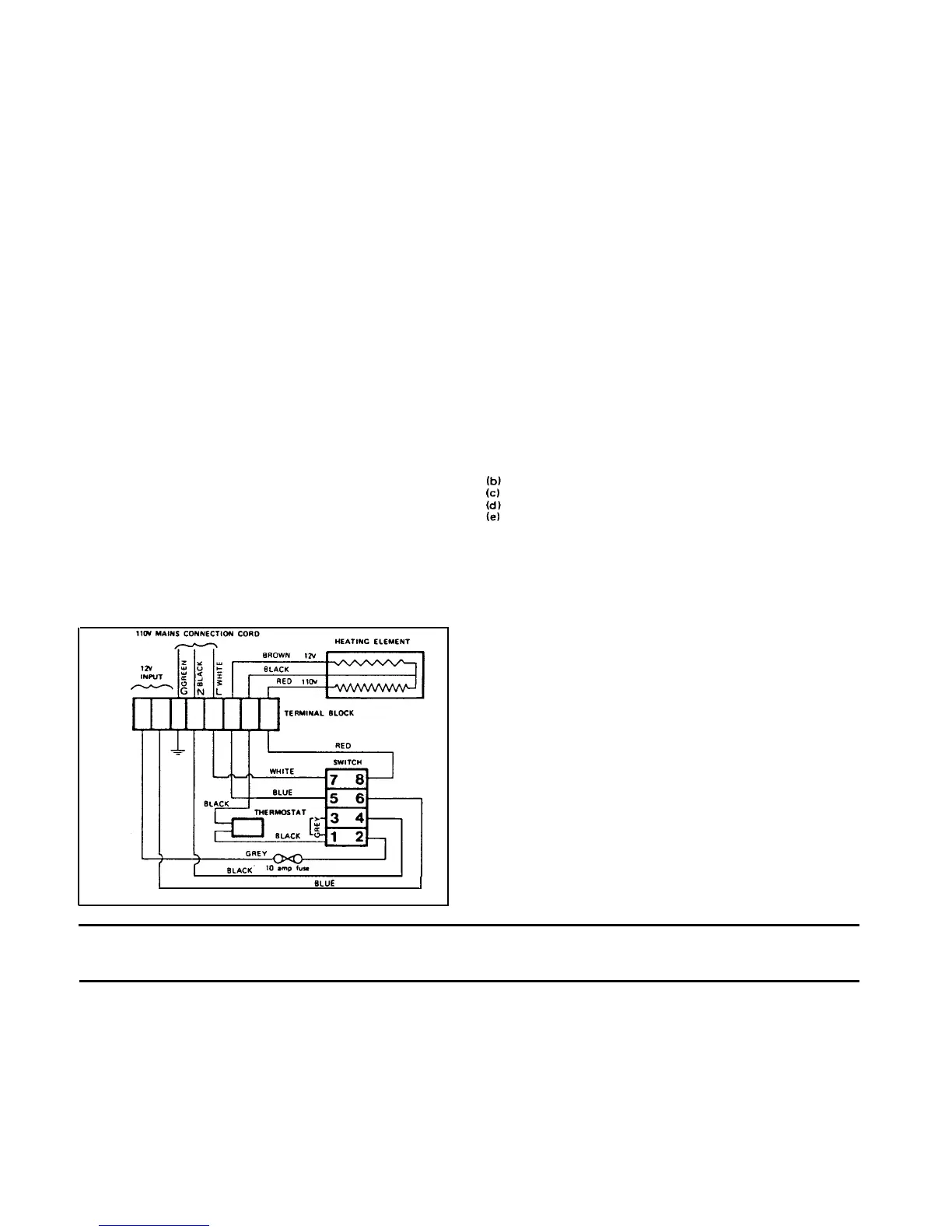

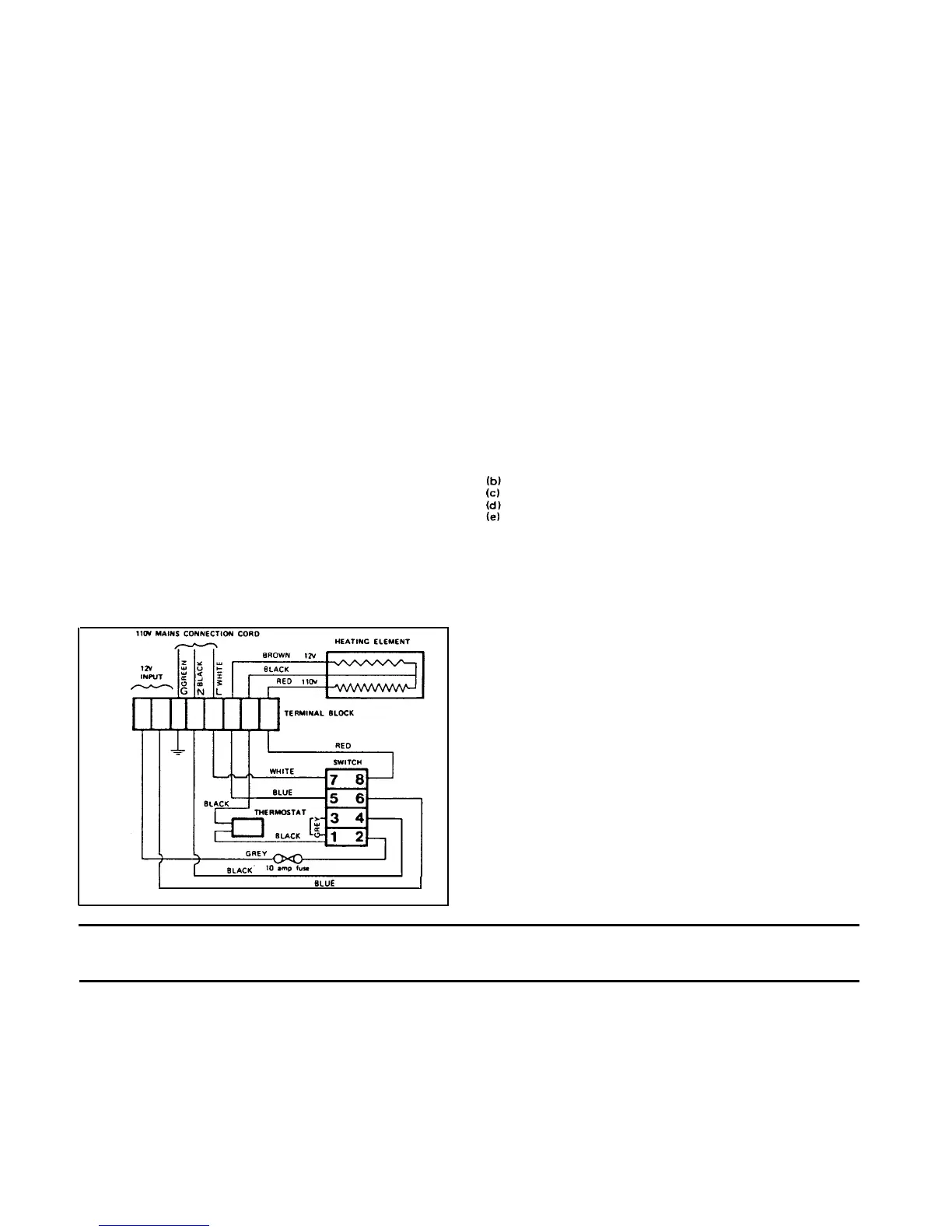

19. ELECTRIC EQUIPMENT

(a)

Heater

Heat is supplied to the boiler of the cooling unit by a 95 watt

heater which has two separate windings, one for use on 12V d.c..

the other for

110V

a.c.

If a new heater has to be fitted at any

time, it will be necessary to disconnect from the electricity supply

and to gain access to the back of the refrigerator.

I

BLUE

I

WIRING

DIAGRAM

1.

2.

3.

4.

5.

6.

7.

Take off the cover from the electric equipment control box by

removing the screw

(H,

fig.

4).

Disconnect the three heater leads

from the terminal block, taking a written note of their respective

positions and being careful not to disturb other connections.

Release the

armoured

sleeve protecting the heater leads from the

top of the control box by removing the retaining plate held by

one screw.

Take out the screws and remove the cover from the opening in the

back of the boiler casing through which the heater is fitted.

Remove sufficient insulation from the boiler through the opening

to gain access to the heater in its metal pocket. Bend back the

retaining wire clip at the top of the pocket, and lift the heater from

the pocket at

the same

time withdrawing its leads from the

armoured

sleeve.

Check that the new heater is of the correct type, then fit it in the

metal boiler pocket, at the same time threading the three leads

through the

armoured

sleeve. (This operation will be assisted if the

ends of the leads are temporarily taped together).

Push the heater fully down in the pocket, then bend the retaining

wire clip over the top to prevent it rising in use.

Connect the leads to the terminal block as before, fix the

armoured

sleeve to the top of the control box with the retaining plate and

screw, and replace the control box cover.

Put back the boiler insulation, packing it around the tubes, refit the

cover. reconnect the refrigerator and test.

If gas connections have been disturbed, test for leaks as in item

9.

(b) Fuse

If there is no circuit when connected to 12 volts, check that the

fuse has not burnt out -see item 7

(c)

20.

TROUBLE

SHOOTING

If refrigerator does not freeze satisfactorily:-

(a)

(f)

(g)

(h)

(i)

(j)

(k)

(I)

(m)

Check that the refrigerator is level in both directions, and that

the proper clearances for air circulation over the cooling unit at

the back have been allowed -see item 3.

Thermostat incorrectly used . . . see item 12.

Evaporator heavily coated with frost . . . see item 15.

Air circulation around cooling unit restricted

.._

see item 3.

Flame has gone out:

i

Gas in bottle used up . . . fit new bottle.

ii Connection between thermocouple and flame failure device

body loose . . . tighten union

(1,

fig. 6) but do not overtighten.

iiiClogged thermostat by-pan screw . . . clean or exchange it.

Flue baffle not inserted into central tube of the cooling

unit

. . . see item 18

(a).

Wrong gas pressure at burner . . . have pressure checked.

Pressure at burner must not fall below 11 ins

w.g.

when thermo-

stat is set on ‘MAX’.

Burner assembly loose . . .

refit.

Jet orifice or burner gauze clogged . . see item 18 (d).

Faulty operation of the thermostat

._.

thermostat will have to be

exchanged for new one.

Electric operation . . . burnt out winding in heater, see item 19

(a).

12V operation . voltage drop due to defective battery. or wiring

from battery to refrigerator not heavy enough . . . see item 7

(b).

12V operation . . . burnt out fuse, see item 7

(c).

Odor from fumes:-

(n)

Flame touches side of the boiler due to displacement of

burner through loose screw or bent bracket . . . correct position

or fit new burner and bracket. Burner displacement may cause

smoke and sooting of the flue.

(o) Burner damaged or gauze choked.

(p)

Flame touches flue

baffle:-

i

Baffle too low in flue . . . see item 18 (a).

ii Gas pressure too high . . . see item 20 (g).

iii Jet orifice has been opened out . . . fit new jet of correct size

(size

4).

(q)

Dirty flue tube; clean flue,, burner and jet as described in item

18

(d).

All the above instructions are to be followed closely. This refrigerator is quality guaranteed, however, we are not responsible for any failures caused

by improper adjustments and unfavorable installation conditions. Contact service point or distributor service department for assistance if

required.

Loading...

Loading...