Final Test Procedures 12–1

Chapter 12 — Final Test Procedures

Leak Tests

Leaks must be repaired before performing other tests or installing the unit for use. Failure

to test the unit can result in core ooding or a damaged unit. After leak testing is complete,

perform the remaining test procedures.

Motor Cavity & Seal Assembly Leak Test

Perform this test whenever the motor housing or mechanical seal assembly has been

disturbed or the controls have ooded. This test will ensure no leaks exist between the motor

head and motor housing and between the mechanical seal assembly and the motor cavity.

1. Use a 1/2-inch socket or wrench to remove the check valve/anti-siphon.

2. Install the air test tting into the ground screw hole and the two control bracket

screws into their holes.

3. Place the pump into a 5 gallon bucket. Add enough water to submerge the motor

head and discharge elbow.

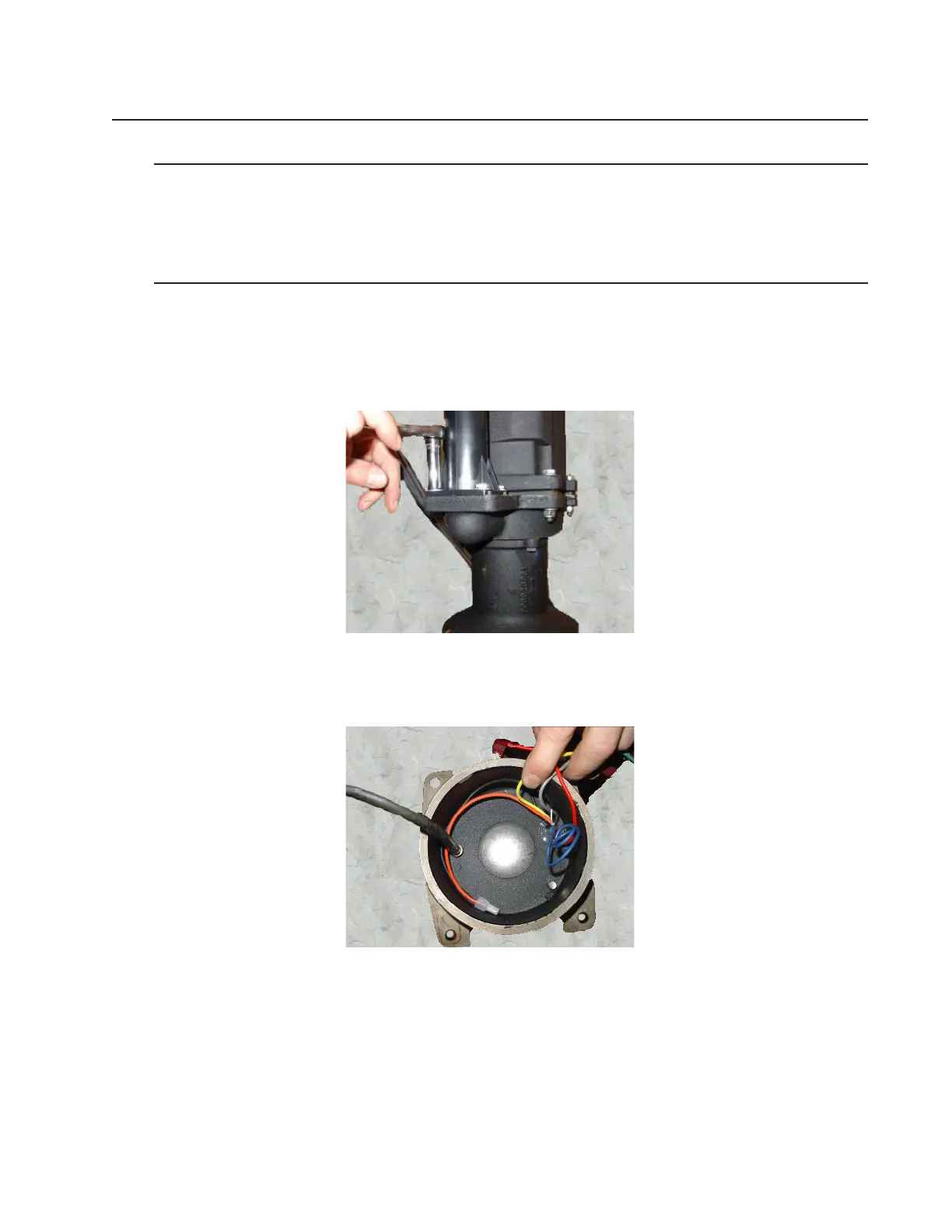

Figure 12-1

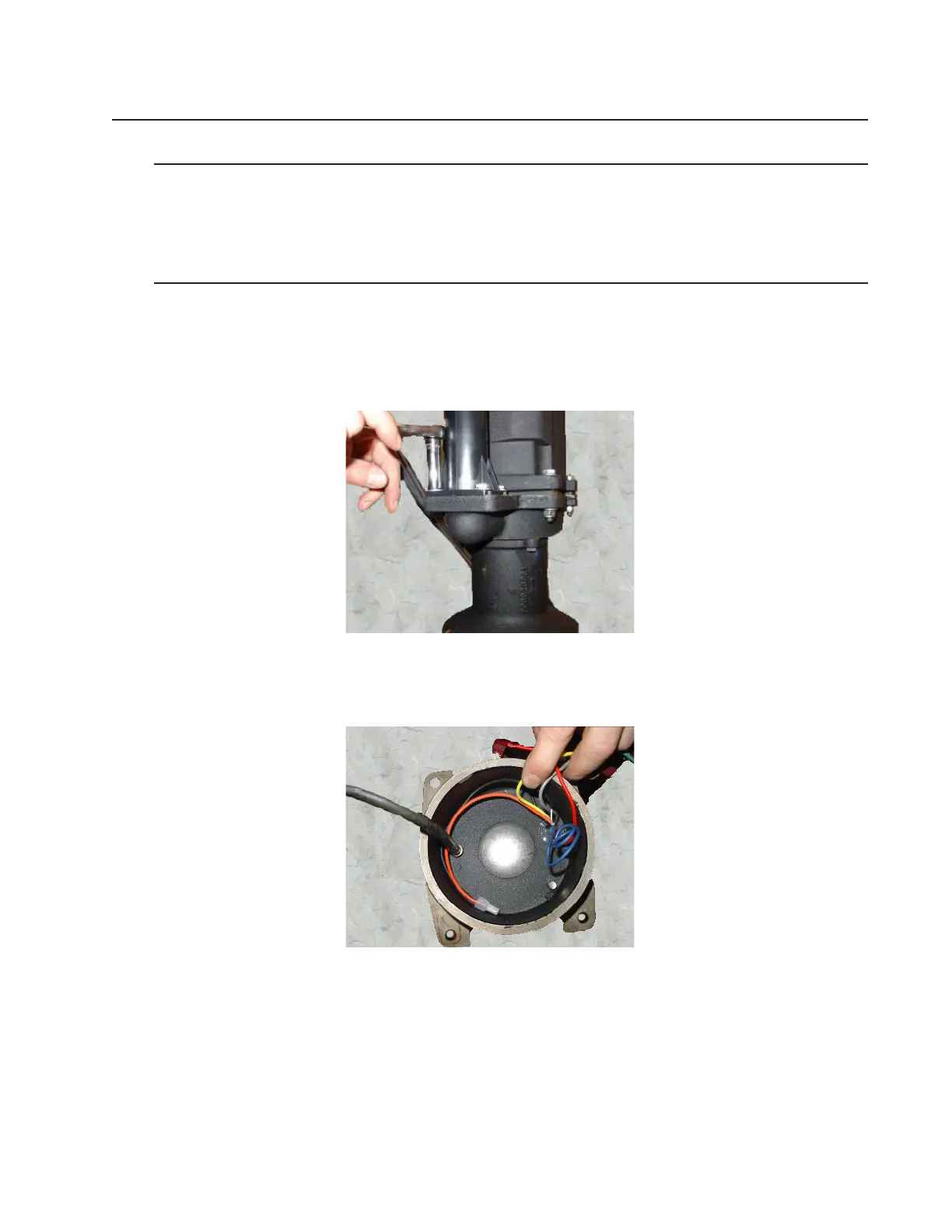

Figure 12-2

Loading...

Loading...