14 EATON EP Control for Heavy Duty Series 2 Piston Pumps Parts & Service 08-10-0002-EN-0901 September 2001

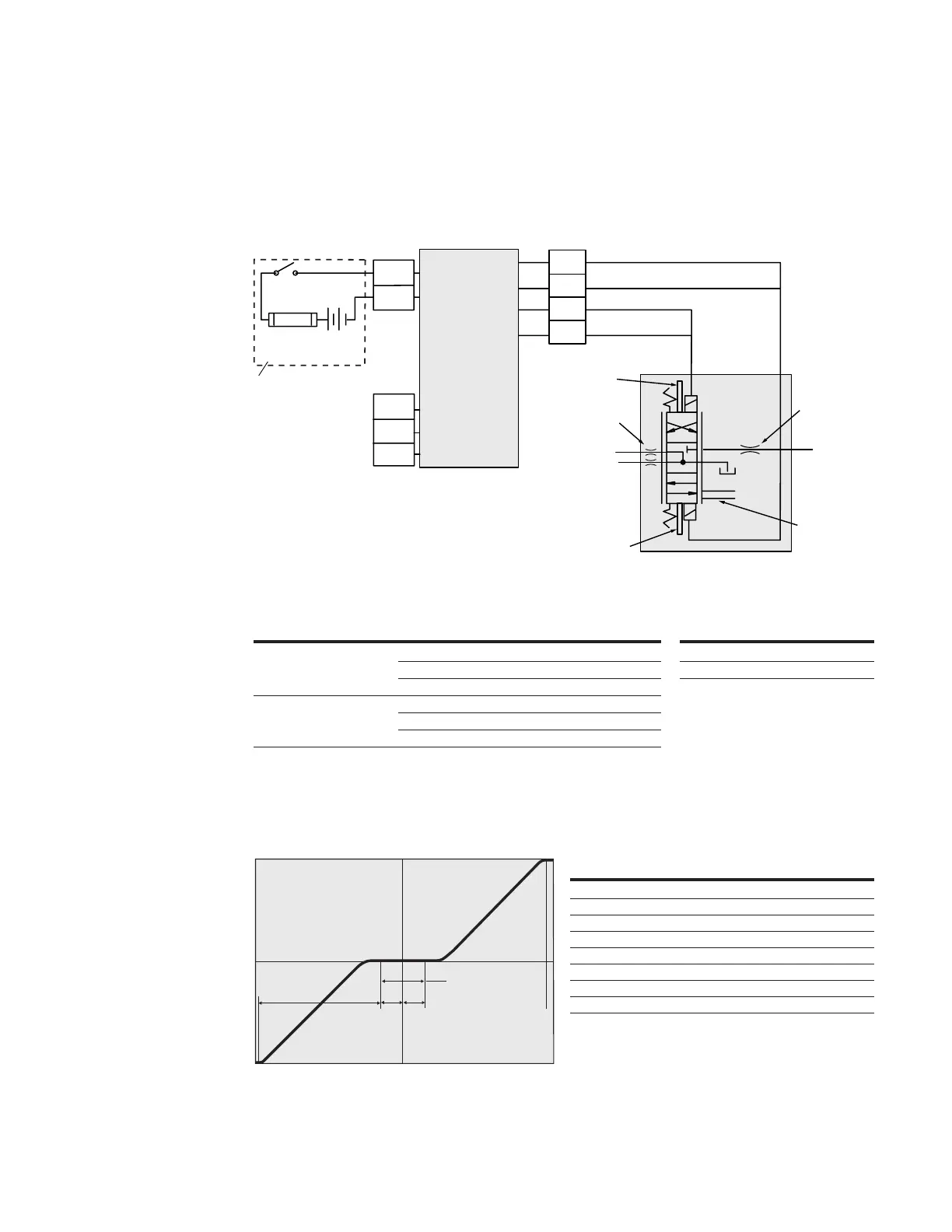

Interconnect

Schematic

A +

B -

POWER

SUPPLY

CONNECTOR

(2-Pin)

see chart

Customer

Supplied

Components

Valve

Assembly

Electronic

Module

Proportional

Solenoid 1

Solenoid

Connector

Proportional

Solenoid 2

S1

S2

P

Mechanical

Swashplate

Feedback

Supply Orifice

(Optional)

Servo Orifices

(Optional)

A

B

C

COMMAND

INPUT SIGNAL

CONNECTOR

(3-Pin)

see chart

Battery or

Power Supply

FUSE

On/Off Switch

+-

A

B

C

D

Power Supply Connector

PINS WIRE COLOR SIGNAL

A Red + Supply Voltage

B Black Supply Return

Fuse Rating

3 Amp SLO-BLO

®

(Time Delay) fuse for

12-24 Vdc system - customer supplied

Command Input Signal Connector

COMMAND INPUT SIGNAL PINS WIRE COLOR SIGNAL

A Black Ref Low - 1 Vdc

1 to 6 Vdc Potentiometric B Green Command (wiper)

C Red Ref Hi - 6 Vdc

A Orange Loop Return

±4-20 mA Current Loop B White Loop In

CNo Connection Required*

*EP Control Electronic Module Mating Connector Kit 990762-000 contains plug

used to seal mating end connector.

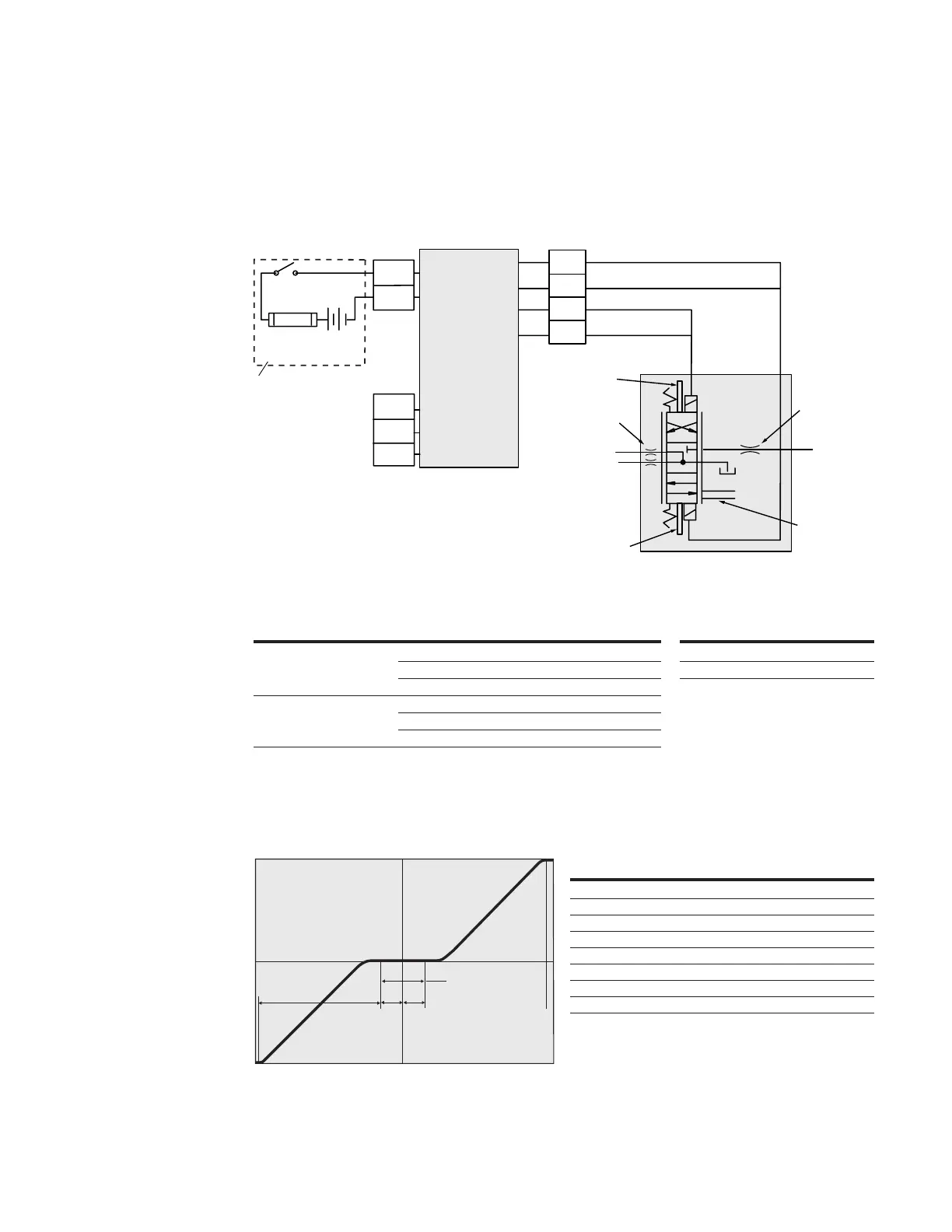

Pump Displacement

vs. Input Signal

Typical Control Characteristics

Full Stroke Port B Flow*

Full Stroke Port A Flow*

Minimum Neutral Range

A

BC D E

*Note: Actual flow direction depends

on pump type and rotation

ABCDE

(MAX) (MIN) (MIN) (MAX)

Command Input Signal

1-6 Vdc 1.5 Vdc 3.3 Vdc 3.5 Vdc 3.7 Vdc 5.5 Vdc

±4-20 mA -20 mA -4.5 mA 0 mA +4.5 mA +20 mA

Shaft Rotation

CCW Solenoid #2 Neither Solenoid #1

Flow OUT port “B” No flow Flow OUT port “A”

CW Solenoid #2 Neither Solenoid #1

Flow OUT port “A” No Flow Flow OUT port “B”

Note: The +20 mA command input signal configuration

operates the pump in one direction. The customer has to

change the polarity on the -20 mA signal to operate the

pump in the opposite direction.

Loading...

Loading...