Effective 6/01

I.B. ATS-RM05

Page 9

4.4 POWER CABLE CONNECTION

POWER CONDUCTORS MAY HAVE VOLTAGE PRE-

SENT THAT CAN CAUSE SEVERE PERSONAL

INJURY OR DEATH. DE-ENERGIZE ALL POWER OR

CONTROL CIRCUIT CONDUCTORS TO BE CON-

NECTED TO THE TRANSFER SWITCH EQUIPMENT

BEFORE BEGINNING TO WORK WITH THE CON-

DUCTORS AND/OR TERMINATING THEM TO THE

EQUIPMENT.

USE CABLE LUGS, NOT DESIGNED FOR THE

TRANSFER SWITCH MAY CAUSE HEATING PROB-

LEMS. BREAKER LUGS ONLY MOUNT TO THE

BREAKER, WHILE TRANSFER SWITCH LUGS

MOUNT TO BOTH THE BREAKER AND THE BUS-

BAR BEHIND THE BREAKER. FOR INSTALLATION

INSTRUCTIONS, REFER TO THE INSTRUCTION

LEAFLET SUPPLIED FOR THE SPECIFIC LUGS.

TO HELP PREVENT COMPONENT DAMAGE OR

FUTURE MALFUNCTIONS, USE EXTREME CARE TO

KEEP CONTAMINANTS OUT OF THE TRANSFER

SWITCH EQUIPMENT WHEN MAKING POWER

CABLE CONNECTIONS.

Test all power cables prior to connection to the unit to

ensure that conductors or cable insulation has not been

damaged while being pulled into position.

Power cables are to be connected to solderless screw

type lugs located on the transfer switch switching

devices. Verify that the lugs supplied will accommodate

the power cables being used. Also verify that the cables

comply with local electrical codes. Standard transfer

switch equipment, as supplied from the factory, will

accommodate the wire sizes shown in Table 4.1.

Carefully strip insulation from the power cables to avoid

nicking or ringing of the conductor strands. Prepare the

stripped conductor termination end by cleaning it with a

wire brush. If aluminum conductors are used, apply an

appropriate joint compound to the clean conductor sur-

face area.

Transfer Switch Number of

Amp Rating Wire Size Range Cables per Phase

30 - 100 #14 - 3/0 1

150 - 200 #6-300MCM 1

Table 4.1 Wire Size for Automatic Transfer Switch

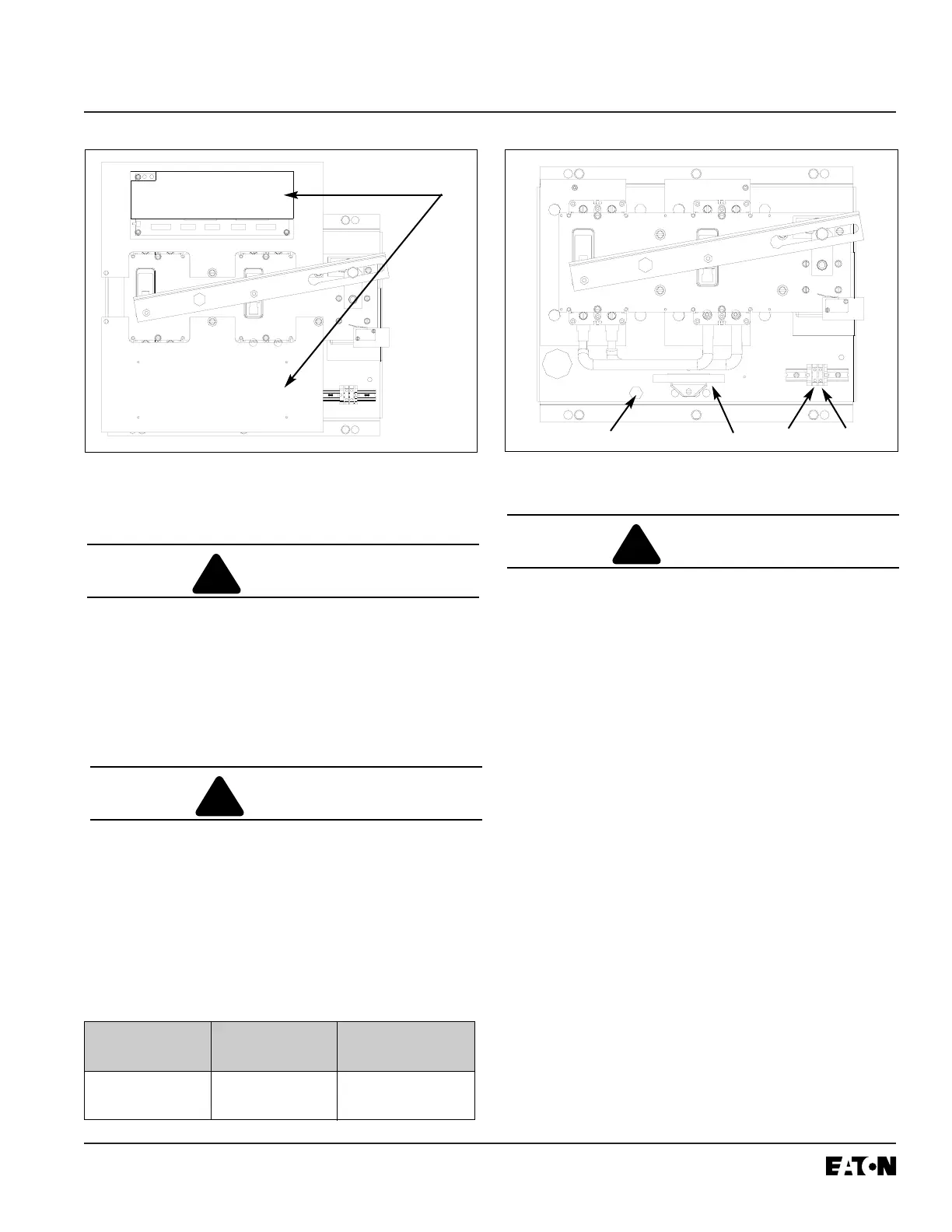

Figure 4-4 Deadfront Removal

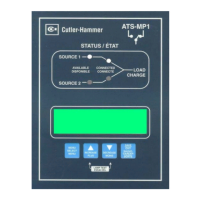

Figure 4-5 Cable Connections

Ground Screw

51

52

Neutral

E1

E2

N1

N2

T1

T2

Loading...

Loading...