Vacuum fault interrupter (VFI)

Eaton’s Cooper Power series VFI transformers utilize

vacuum interrupters to provide fault current interruption and

load make/break switching capabilities. The VFI transformer

uses the same technology used in Eaton’s Cooper Power

series VFI pad-mounted switchgear.

VFI transformers can be specified for either transformer

protection or loop protection. A VFI transformer with

transformer protection protects the transformer and

provides proper coordination with upstream protective

devices. A VFI transformer with loop protection protects

the loop or downstream section of a feeder. Consequently,

when a fault occurs downstream, the VFI breaker trips and

isolates the fault, leaving the transformer load uninterrupted.

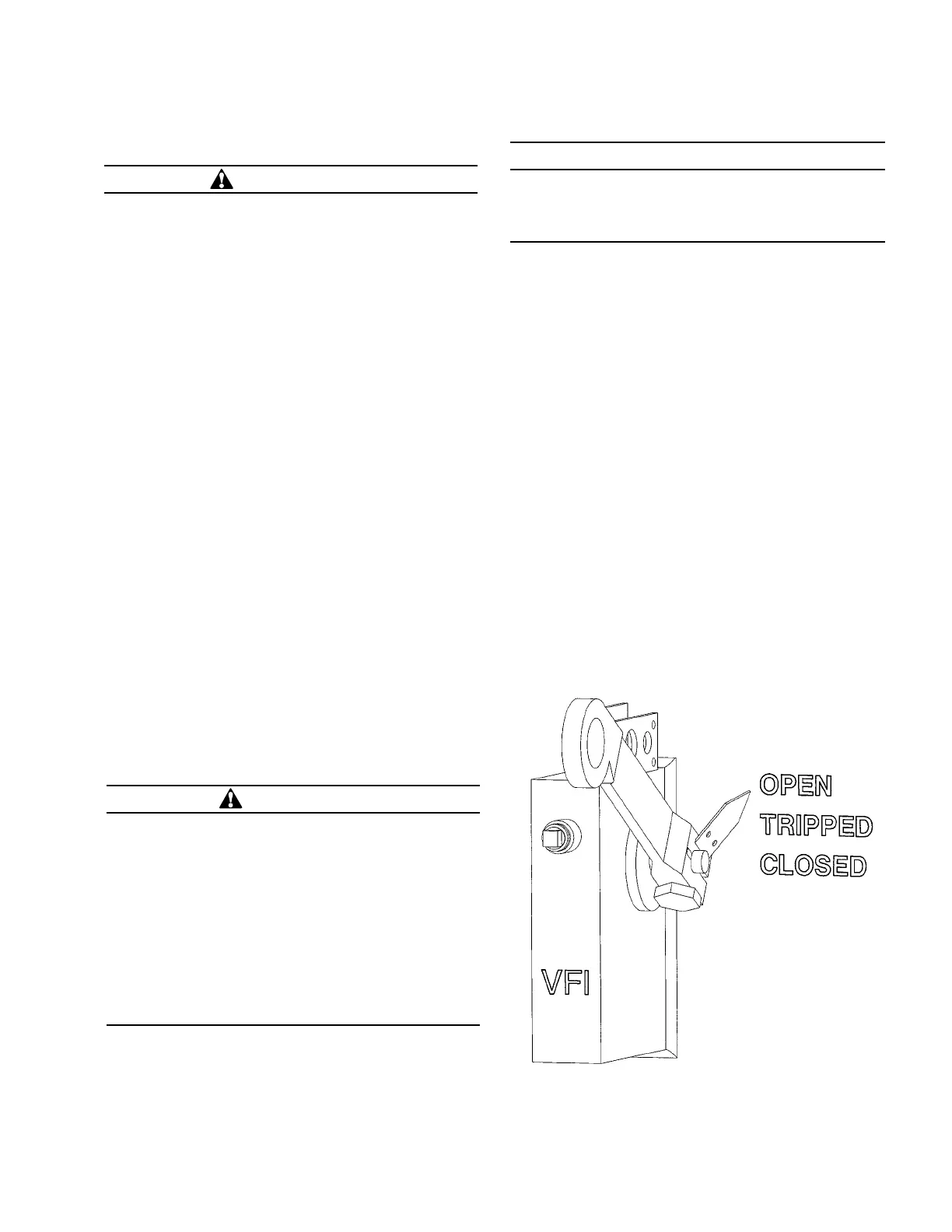

The VFI interrupter mechanism in a VFI transformer has a

hotstick-operable handle located on the faceplate of the

transformer, with the operating mechanisms configured

for ganged three-phase operation (see Figure 24). The VFI

interrupter mechanism is opened by pulling the operation

handle down to the open position. The VFI interrupter

mechanism is closed by briskly pushing the handle up,

into the closed position. If the VFI interrupter mechanism

has tripped as the result of a fault or overload condition,

the mechanism must be reset before it can be closed. To

reset the mechanism, firmly pull the operation handle down

toward the ground until the latch resets. After the latch has

been successfully re-set, the VFI interrupter mechanism can

be closed normally.

Figure 24. VFI operating handle.

IMPORTANT

For 75 °C AWR transformers, applications with

maximum ambient temperatures exceeding 30 °C or

loading in excess of nameplate rating, contact your

Eaton representative.

WARNING

Hazardous voltage. Can cause severe injury, death, or

damage to equipment.

• Do not operate loadbreak equipment if a fault

condition is suspected. Doing so can cause an

explosion or fire.

• Use a hotstick to operate transformer loadbreak

equipment.

• After operating transformer loadbreak equipment,

check that voltages at transformer terminals are

the expected values. Checking voltages verifies that

loadbreak equipment operated properly and that

electrical circuit conditions are as expected.

• Before servicing transformer secondary connected

equipment, verify that all transformer secondary

terminals have zero voltage and ground the

transformer secondary terminals following industry

accepted safe grounding practices. Grounding

secondary terminals protects against situations such

as a standby generator energizing transformer from

the secondary circuit.

• Before servicing transformer, ALWAYS de-energize

the transformer from a remote upstream source and

then proceed to ground all primary and secondary

transformer terminals following industry accepted

safe grounding practices. Grounding secondary

terminals protects against situations such as a

standby generator energizing transformer from the

secondary circuit.

• Follow industry accepted safety practices. Utilize

protective clothing and equipment when working

with loadbreak equipment.

WARNING

Three-phase pad-mounted transformers use

conventional transformer oil, R-Temp fluid, or

Envirotemp™ FR3™ fluid for an insulating liquid. When

the insulating liquid temperature is less than -20 °C

(-4 °F) for conventional transformer oil, less than 0 °C

(32 °F) for R-Temp fluid or less than -10 °C (14 °F) for

Envirotemp™ FR3™ fluid, viscosity is reduced, which

may reduce make and break capabilities of loadbreak

devices. Below these temperatures, under-oil loadbreak

accessories should not be used to make or break a

load. Instead, de-energize transformer from a remote

upstream source before operating under-oil loadbreak

devices.

15Three-phase pad-mounted compartmental type installation and maintenance instructions MN202001EN August 2015

Loading...

Loading...