Bushing removal and replacement

1. Verify that tank is grounded. De-energize transformer

from a remote upstream source. Ground all bushings

and terminals before performing maintenance on

bushings.

2. Open tank by removing tank cover or manhole/

handhole cover as outlined in Tank Cover Removal

and Installation section of this manual.

3. Lower insulating liquid level as outlined in Insulating

Liquid Maintenance section of this manual. Lower liq-

uid level to completely expose the bushing.

4. Disconnect all internal and external cable and leads.

Note position of all nuts, flat washers, spring washers,

etc., so they can be re-installed in same locations.

5. Remove all bushing clamp hardware, noting position of

all nuts, flat washers, spring washers, etc., so they can

be re-installed in same locations.

6. Remove external bushing clamp, bushing, and gasket.

7. Install a new bushing and gasket. Center bushing

and gasket to obtain an effective seal. Install exterior

bushing clamp and clamp hardware. Tighten clamp nuts

per torque specified in Table 1.

8. Re-connect all external and internal cables and leads.

Replace all nuts, flat washers, spring washers, etc., in

their original position. Tighten all connections per torque

specified in Table 1.

9. Restore insulating liquid to appropriate level as outlined

in Insulating Liquid Maintenance section of this

manual. Close, reseal, and leak test tank as outlined

in the Tank Cover Removal and Installation section of

this manual. Inspect bushing-to-tank seal for leaks or

seepage.

Cabinet removal and installation

Cabinet removal

1. Verify that tank is grounded. De-energize transformer

from a remote upstream source. Ground all bushings and

terminals before performing maintenance on cabinet.

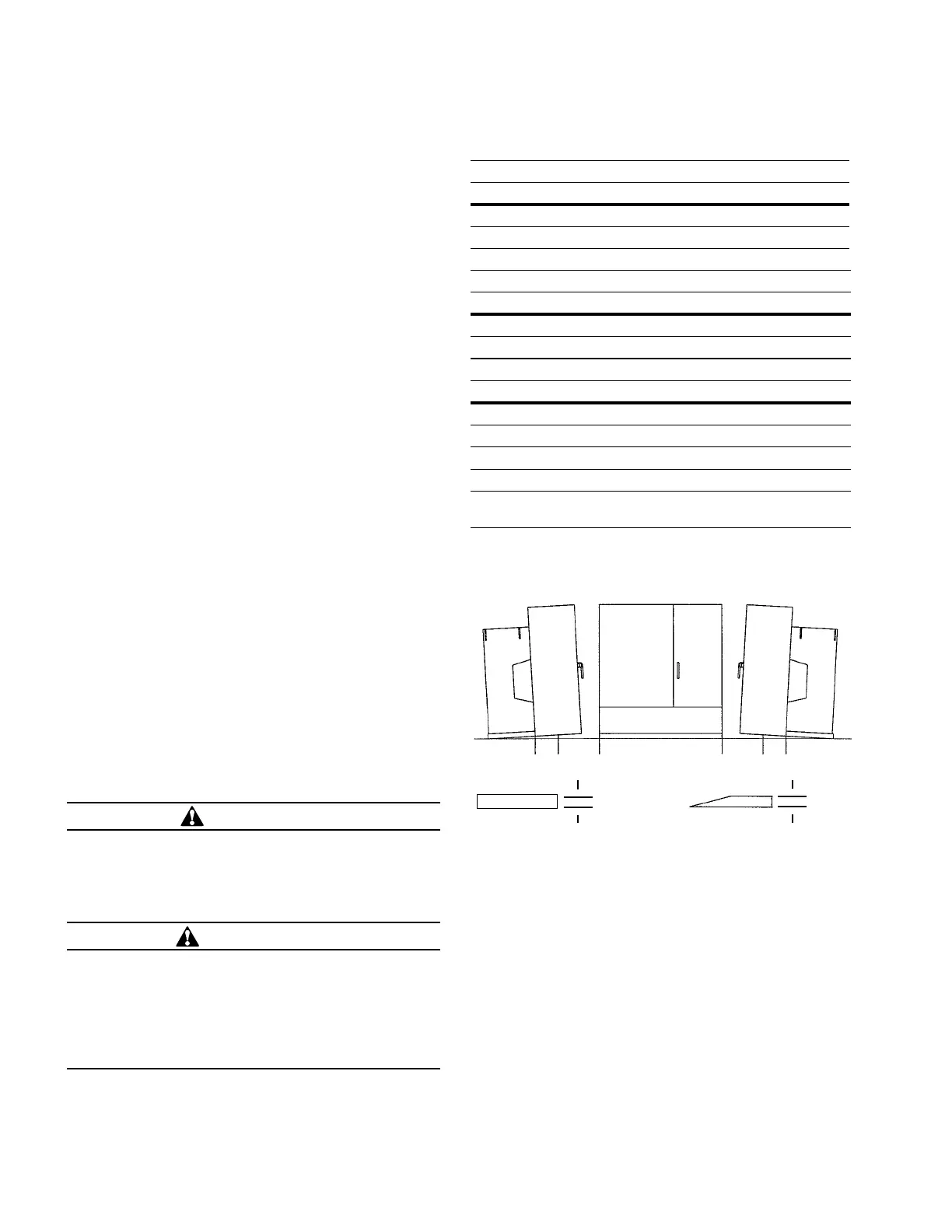

2. Place one 1/4 to 3/8 inch shim directly below faceplate

on both sides of tank at points A and A’ (see Figure 28).

3. Place one 1 1/2 inch wedge under each side of cabinet

at points B and B’ to relieve strain on the cabinet.

4. Note position and orientation of gasket that is between

top of cabinet and tank so it can be re-installed in same

fashion.

5. Disconnect HV-LV barrier from vertical bracket of face-

plate.

Bushing Clamps

Clamp Type Hardware Tightening Torque

Cast Aluminum Clamp 70-80 in-lbs.

Molded Polymer Tri-Clamp 40-60 in-lbs.

All other 3 & 4 hole Clamps 40-60 in-lbs.

Table 1. Bushing Hardware Tightening Torque

Bushings With Internal Spade Connections

Bushing Hardware Hardware Tightening Torque

1/2” Steel (Grade 8) 50 ft-lbs.

3/8” Steel (Grade 8) 50 ft-lbs.

Bushings With Internal Stud Connections

Bushing Hardware Hardware Tightening Torque

3/8”-16 Brass Nuts 16 ft-lbs.

5/8”-11 Aluminum Nuts 60 ft-lbs.

5/8”-11 Brass Nuts 75 ft-lbs.

1”-14 Brass Nuts 121 ft-lbs.

Bushing Lead Block,

1/2” Steel Hardware

110 ft-lbs.

Right

Side

of

Cabinet

Left

Side

of

Tank

Front of Cabinet

Right

Side

of

Tank

A B A B A’ B’ B’ A’

Left

Side of

Cabinet

Shim 1 1/2 inch

1/4 to 3/8 inch

Wedge

Figure 28. Cabinet removal diagram.

CAUTION

Potential Falling Object. Can cause personal injury or

damage to transformer. Do not open cabinet doors

when cabinet is removed from transformer tank.

Opening cabinet doors will cause cabinet to fall

forward.

WARNING

Hazardous voltage. Can cause severe injury, death, or

damage to equipment. De-energize transformer from

a remote upstream source before opening cabinet

and doing cabinet interior inspection or maintenance.

Check that all transformer terminals and bushings have

zero voltage. Ground transformer following industry

accepted safe grounding practices.

22 Three-phase pad-mounted compartmental type installation and maintenance instructions MN202001EN August 2015

Loading...

Loading...