MAINTENANCE CS-2511T

42 X7503332503

© 11/19 ECHO Incorporated

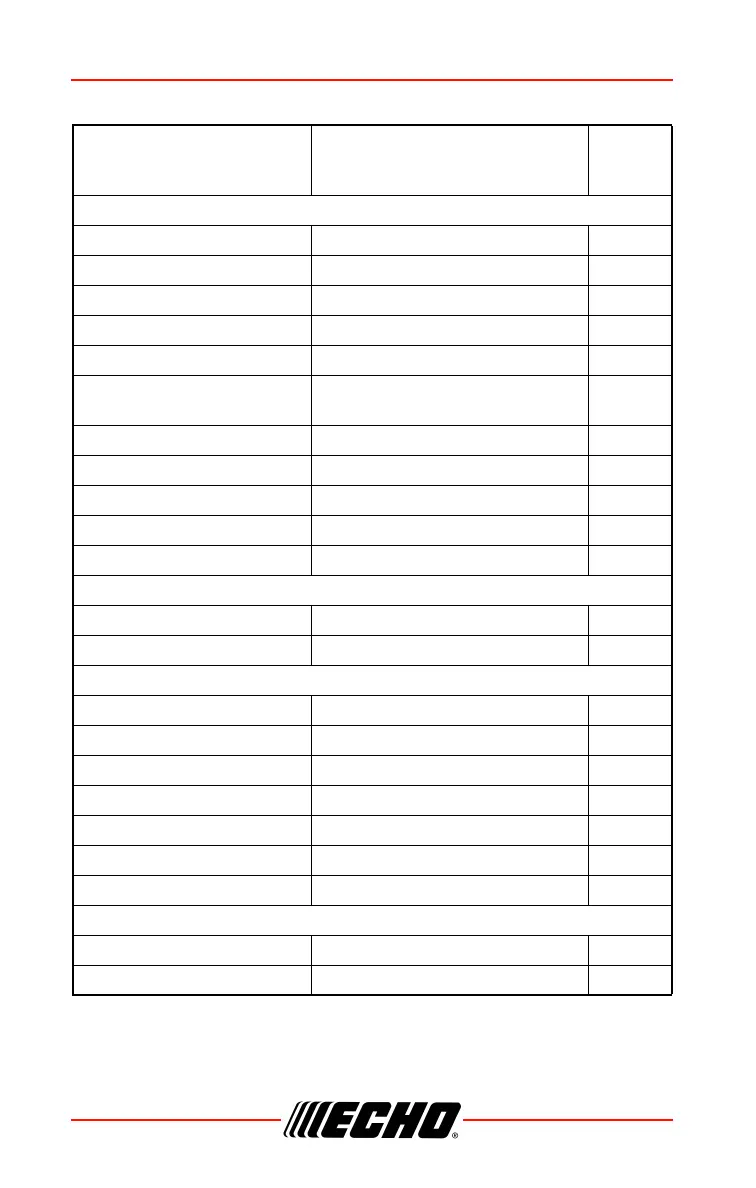

Maintenance Intervals

IMPORTANT NOTE - Time intervals shown are maximum. Actual use and

your experience will determine the frequency of required maintenance.

COMPONENT / SYSTEM MAINTENANCE PROCEDURE

REQ’D

SKILL

LEVEL

Daily or Before Use

Air Filter Inspect / Clean * 1

Automatic Oiler Inspect / Adjust 1

Oil Filter Inspect 1

Fuel System Inspect

1

1

Guide Bar & Sprocket Nose Inspect / Clean * 1

Saw Chain Inspect / Sharpen / Replace / Ten-

sioning *

2

Sprocket Inspect / Replace * 2

Cooling System Inspect / Clean 2

Recoil Starter Rope Inspect / Clean * 1

Screws / Nuts / Bolts Inspect / Tighten / Replace * 1

Lifting Hook Inspect

2

1

Every Refuel

Fuel System Inspect

1

1

Guide Bar & Sprocket Nose Inspect 1

3 Months

Air Filter Replace * 1

Oil Filter Inspect / Replace * 1

Fuel Filter Inspect * 1

Fuel Cap Gasket Inspect * 1

Spark Plug Inspect / Clean / Replace * 1

Muffler Spark Arrestor Inspect/Clean/Replace * 2

Cylinder Exhaust Port Inspect / Clean / De-carbon 2

Yearly

Fuel Filter Inspect / Replace * 1

Fuel Cap Gasket Replace * 1