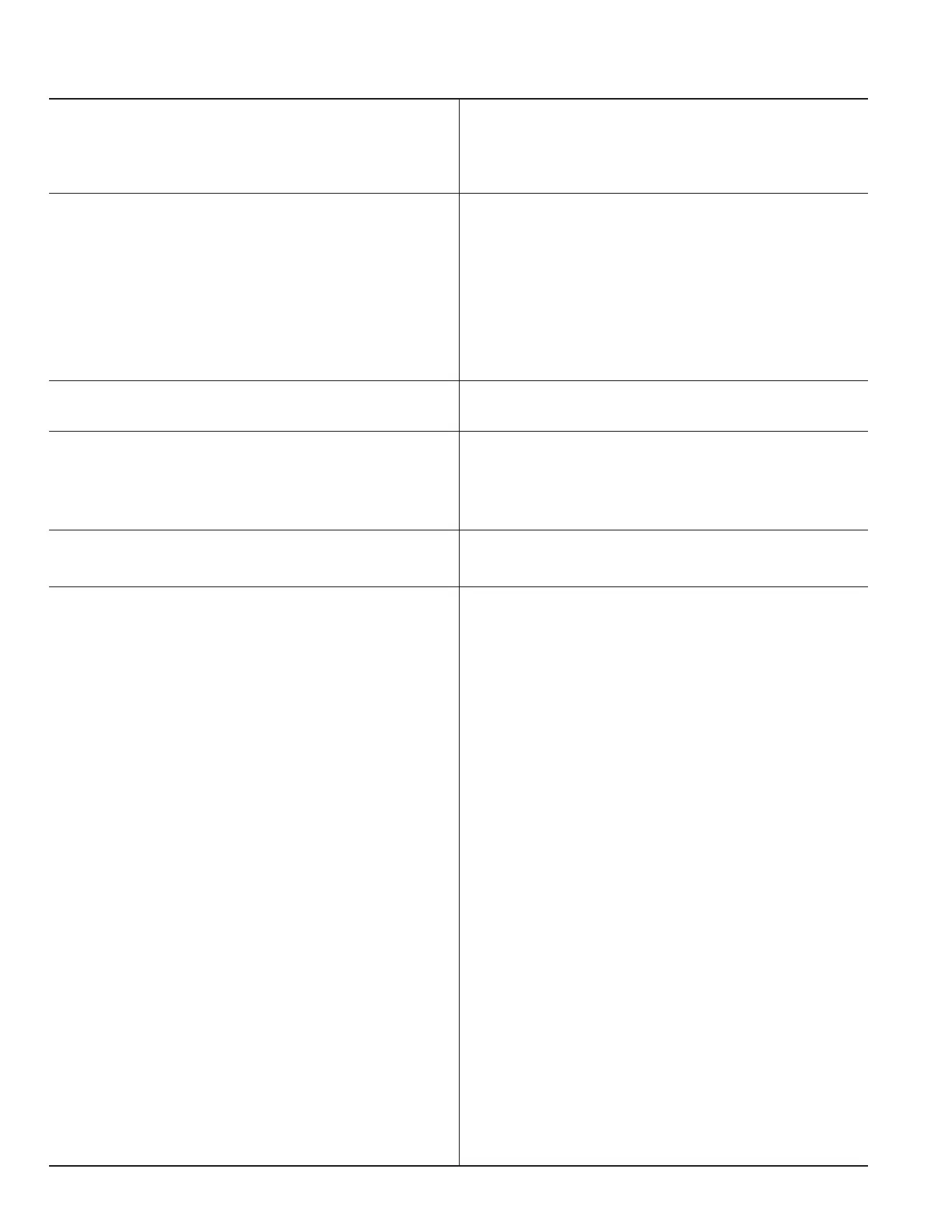

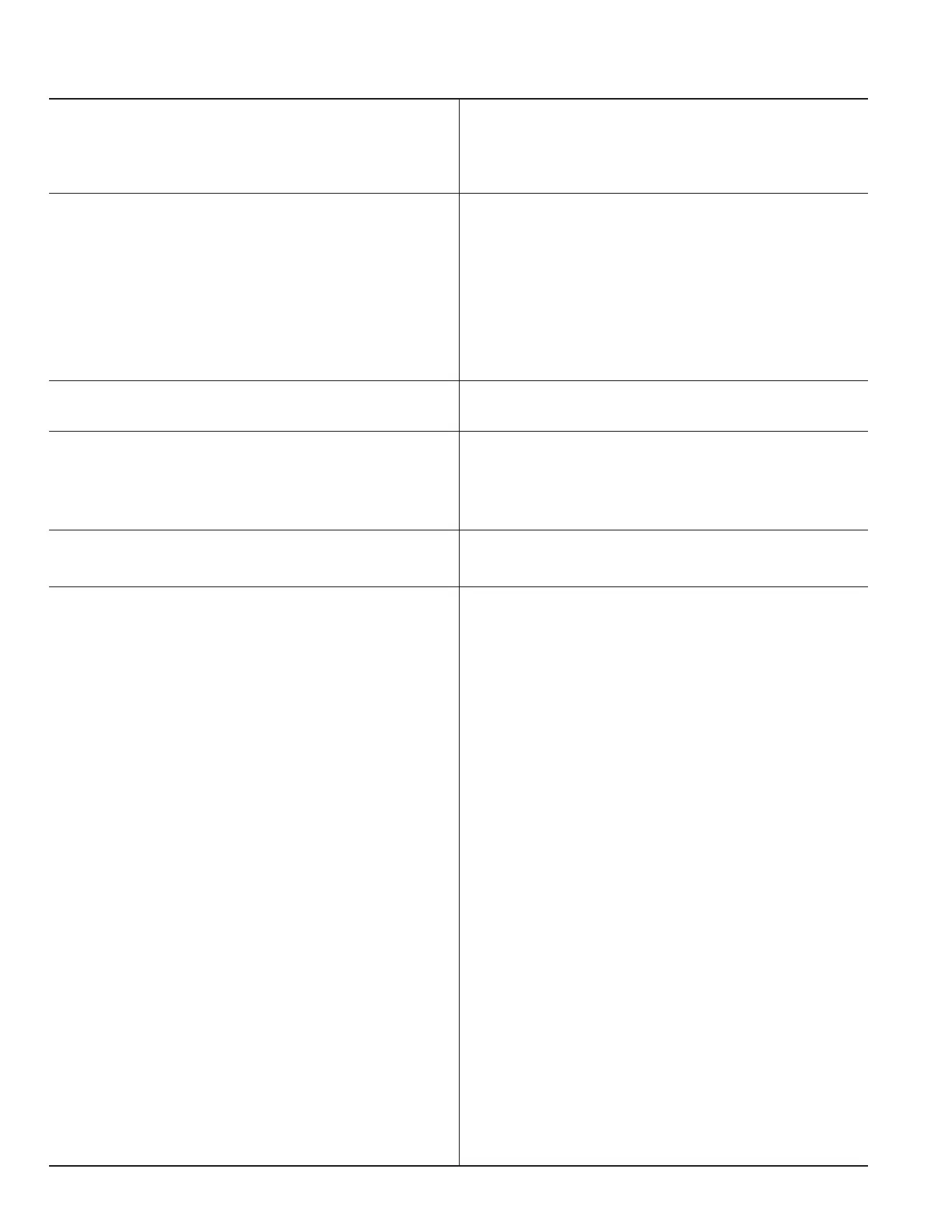

16

2. Check fuse on the board - replace if necessary (1 amp

slow-blow fuse).

3. Check that time delay potentiometer is fully counter

clockwise.

1. Check Rinse Dispenser - Service as necessary.

rinse.

a. If product dispensed. Replace check valve.

b. If no product dispensed. Replace peristaltic tubing.

as needed.

4. Check squeeze tube for wear and replace if in doubt.

problem.

1. Check tubing connections for air leaks.

2. Check for high rinse pressure - optimum is 15-20 psig (1-

1.4 BAR) and cannot be over 35 psig (2.4 BAR).

3. Check squeeze tube for wear and cracks etc.

1. Lubricate, use only silicon grease lubricate.

2. Replace roller assembly.

1. Remove squeeze tube - if fuse does not blow, replace roller

assembly.

2. If fuse blows, disconnect pump motor leads from terminals

3 and 4 activate Rinse Speed Control P.C Board.

a. If fuse blows, replace Speed Rinse Control P.C.

Board.

b. If fuse does not blow, replace pump motor.

9.8 Rinse Injector does not activate

(continued).

9.10 Rinse Injector runs continuously

9.11 Rinse Injector will not prime.

9.12 Excessive squeeze tube wear.

9.13 Fuse on Speed Rinse P.C. board is

blowing repeatedly.

9.9 Rinse Injector runs, no rinse additive be-

ing injected.

Loading...

Loading...