Safety and operating instructions

© Construction Tools GmbH | 33905146 01 | 2019-09-05

Original Instructions

49

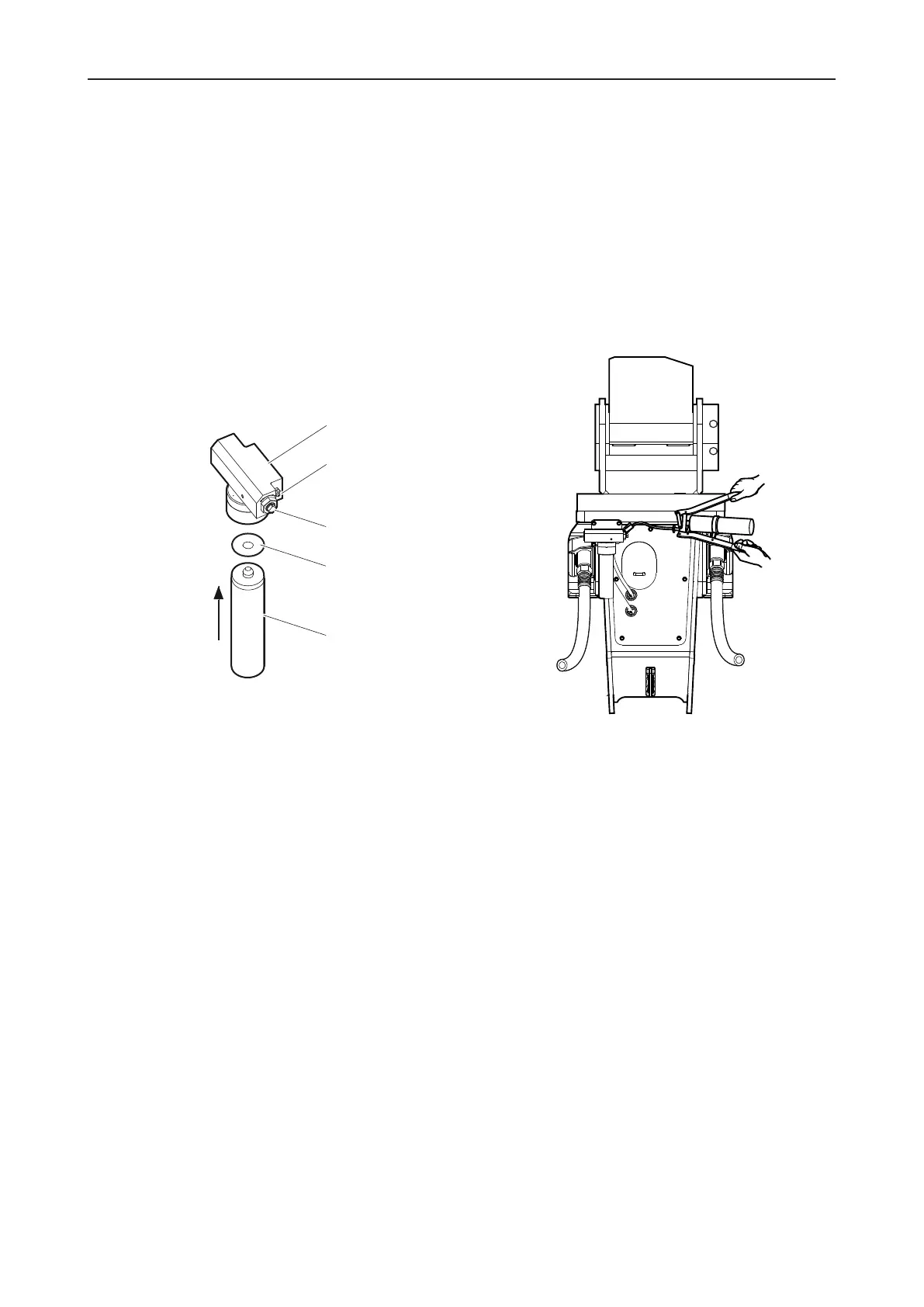

7.4.5 ContiLube®II operation

Please remember the following:

• The ContiLube

®

II (C) is self-venting, i.e. the system

does not require you to vent it.

• The lubricant level in the transparent cartridge(E) of

recyclable PE plastic can always be checked from

the cab by looking at the position of the red piston.

• The piston side of the cartridge(E) must never be

sealed, otherwise no grease supply will be possible.

• You can change the supply volume by adjusting the

metering screw(A), depending on the actual use.

• Tighten the screw clockwise = less grease

• Loosen the screw counter-clockwise = more grease

The pump unit(C) must always be sealed to prevent the

ingestion of water and dust.

n

Use a dust cover or leave the empty cartridge in the

pump until a new cartridge is available.

n

Check the tightness of the connections of all hoses

for the ContiLube

®

II operation once a week.

Emergency lubrication is possible via the grease nip-

ple(B) on the side of the ContiLube

®

II.

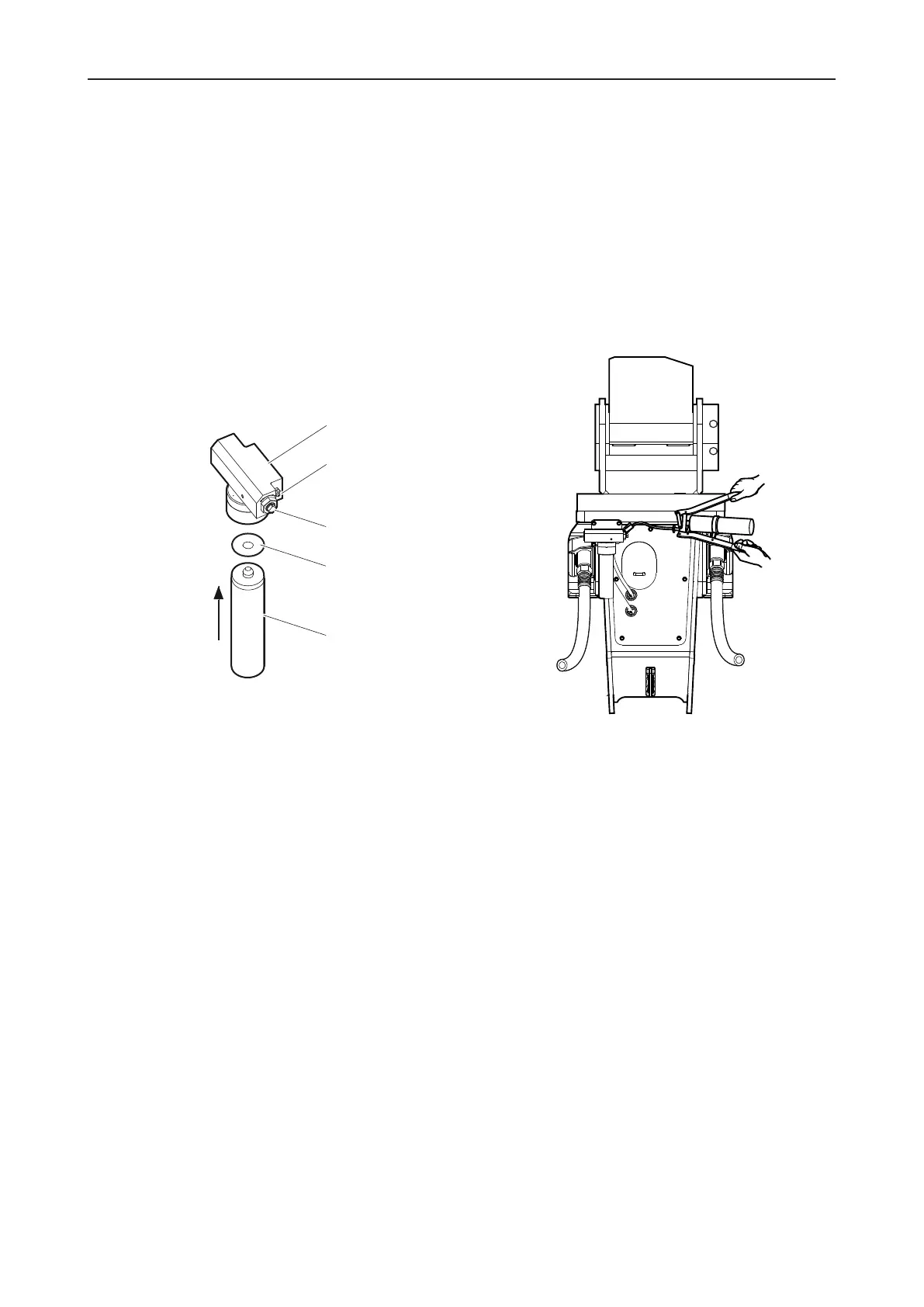

7.4.6 Manual lubrication

Manual lubrication is required if the automatic lubrication

system fails to work.

n

Place the hydraulic breaker at a right angle on the

working tool and exert pressure.

n

Only use chisel paste for lubrication.

n

Put the manual grease gun on the grease nipple of

the emergency lubrication system and inject chisel

paste.

• Lubrication interval: approx. every 2 hours

• 5 to 15 strokes from the manual grease gun

Loading...

Loading...