6 MAINTENANCE

0440 001 001

- 19 -

© ESAB AB 2020

6 MAINTENANCE

NOTE!

Regular maintenance is important for safe and reliable operation.

CAUTION!

All warranty undertakings from the supplier cease to apply if the customer attempts

any work to rectify any faults in the product during the warranty period.

6.1 Inspection and cleaning

Power source

• Check regularly that the power source is free from dirt.

• How often and which cleaning methods apply depend on: the welding process, arc

times, placement, and the surrounding environment. It is normally sufficient to blow the

dust out of the power source with dry compressed air (reduced pressure) once a year.

• Clogged or blocked air inlets and outlets otherwise result in overheating.

Welding torch

• The welding torch's wear parts should be cleaned and replaced at regular intervals in

order to achieve trouble-free wire feed. Blow the wire guide clean regularly and clean

the contact tip.

6.2 Changing the wire liner

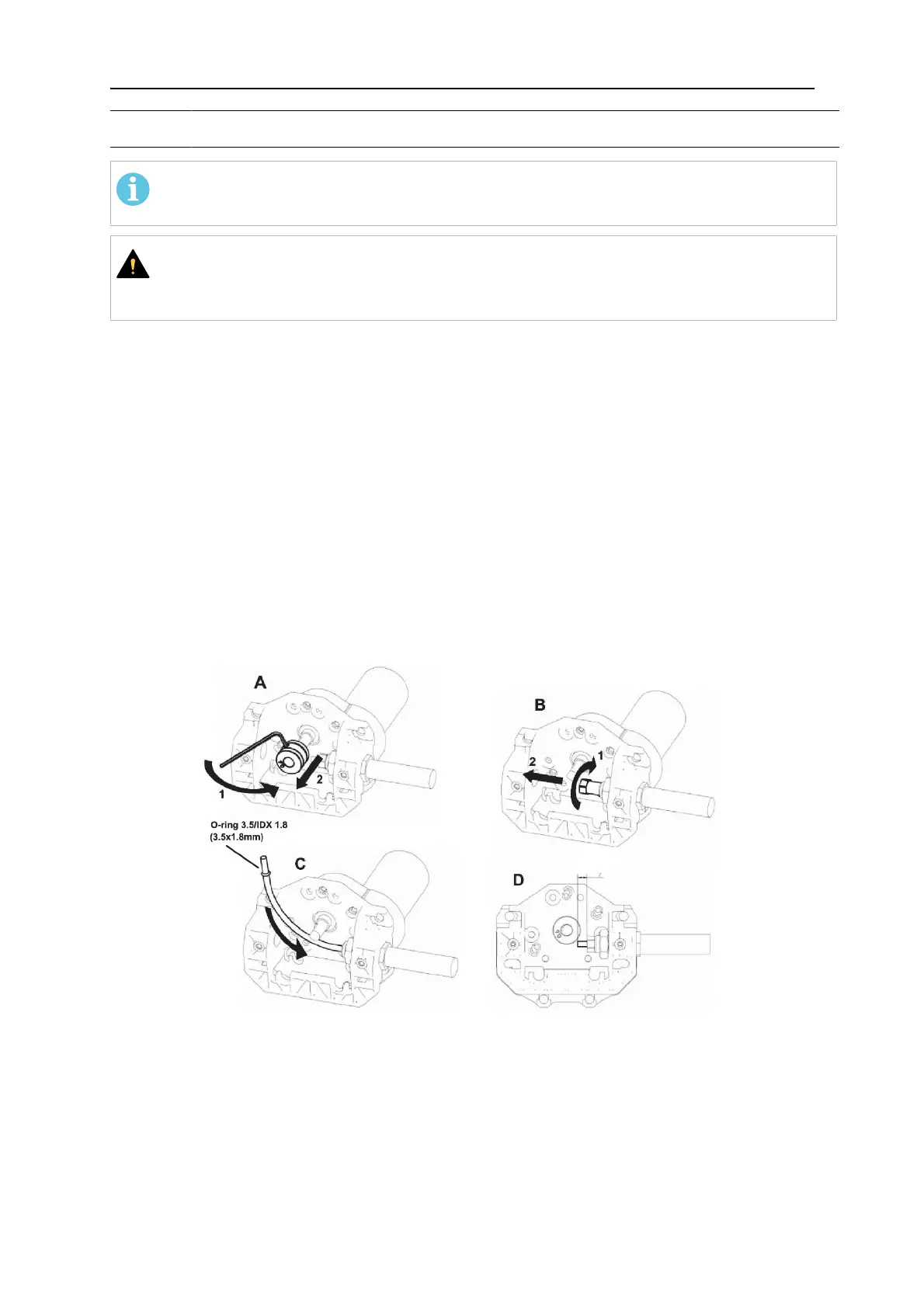

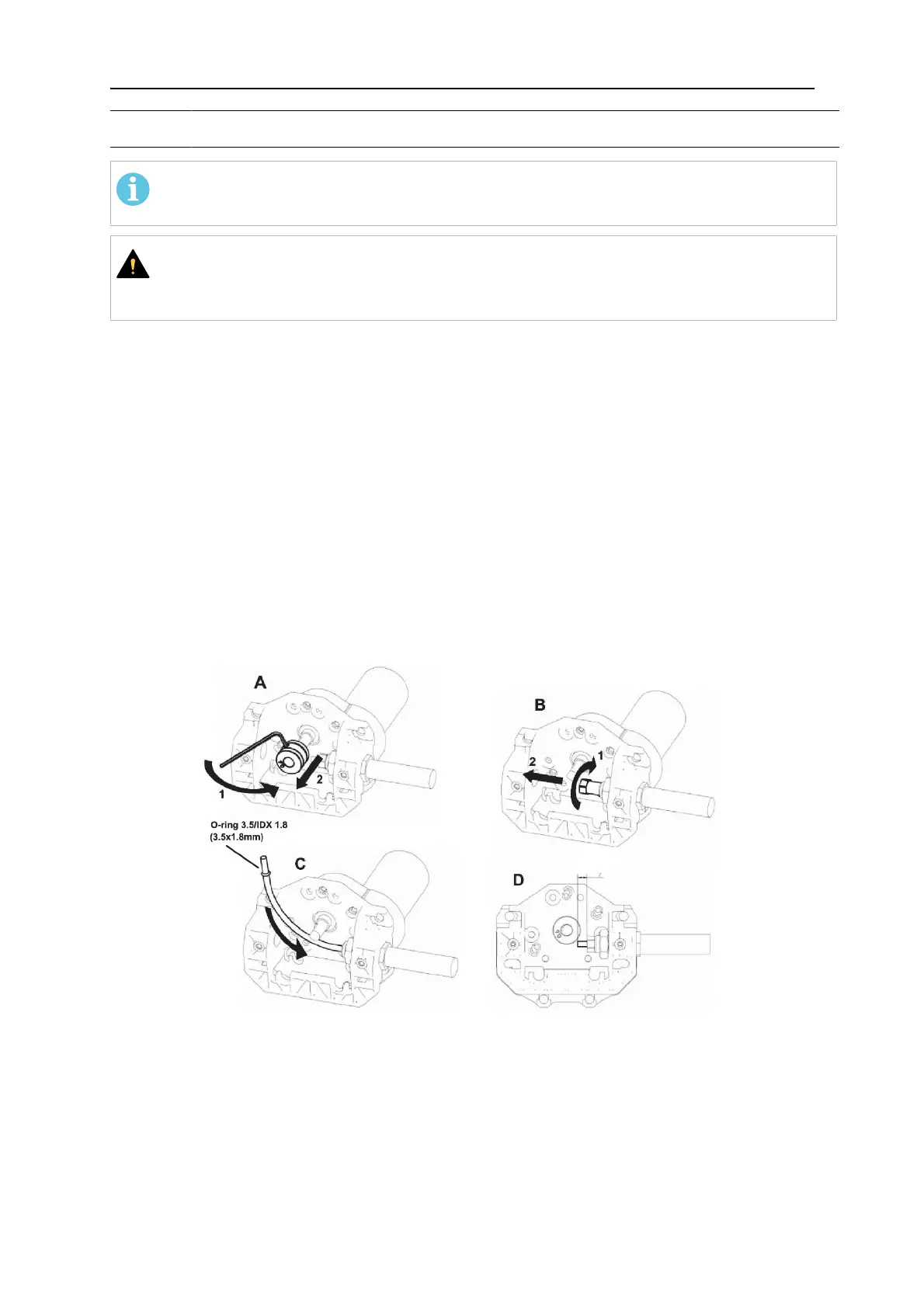

A. Loosen the fixing screw and take the roller off the axle.

B. Loosen the adaptor nut, straighten the torch cable and remove the liner.

C. Insert the replacement liner into the straightened cable until it touches the contact tip.

D. Lock the liner with adaptor nut. Cut excess of liner so it sticks 7 mm out of tip adaptor.

Loading...

Loading...