-- 1 1 --

ba41d1ea

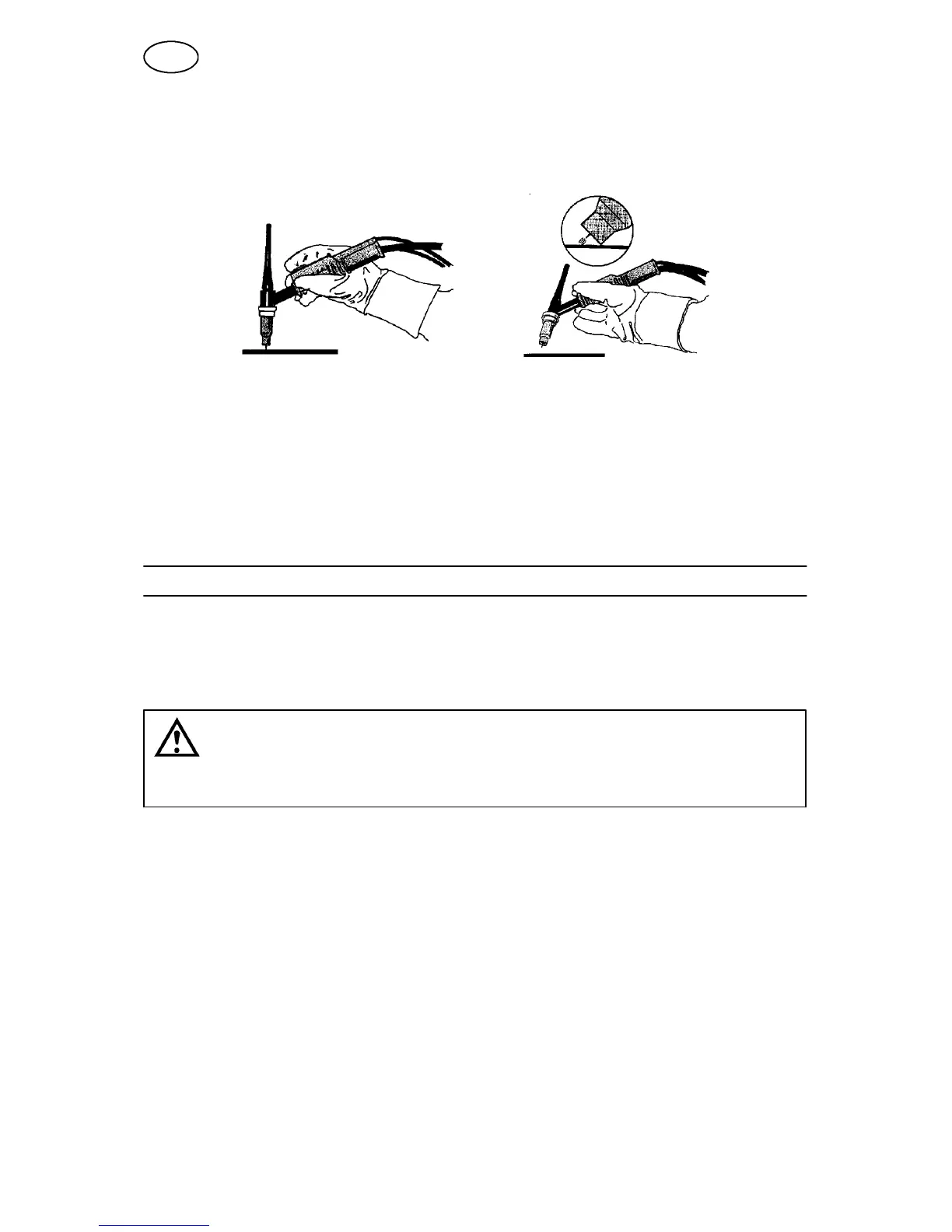

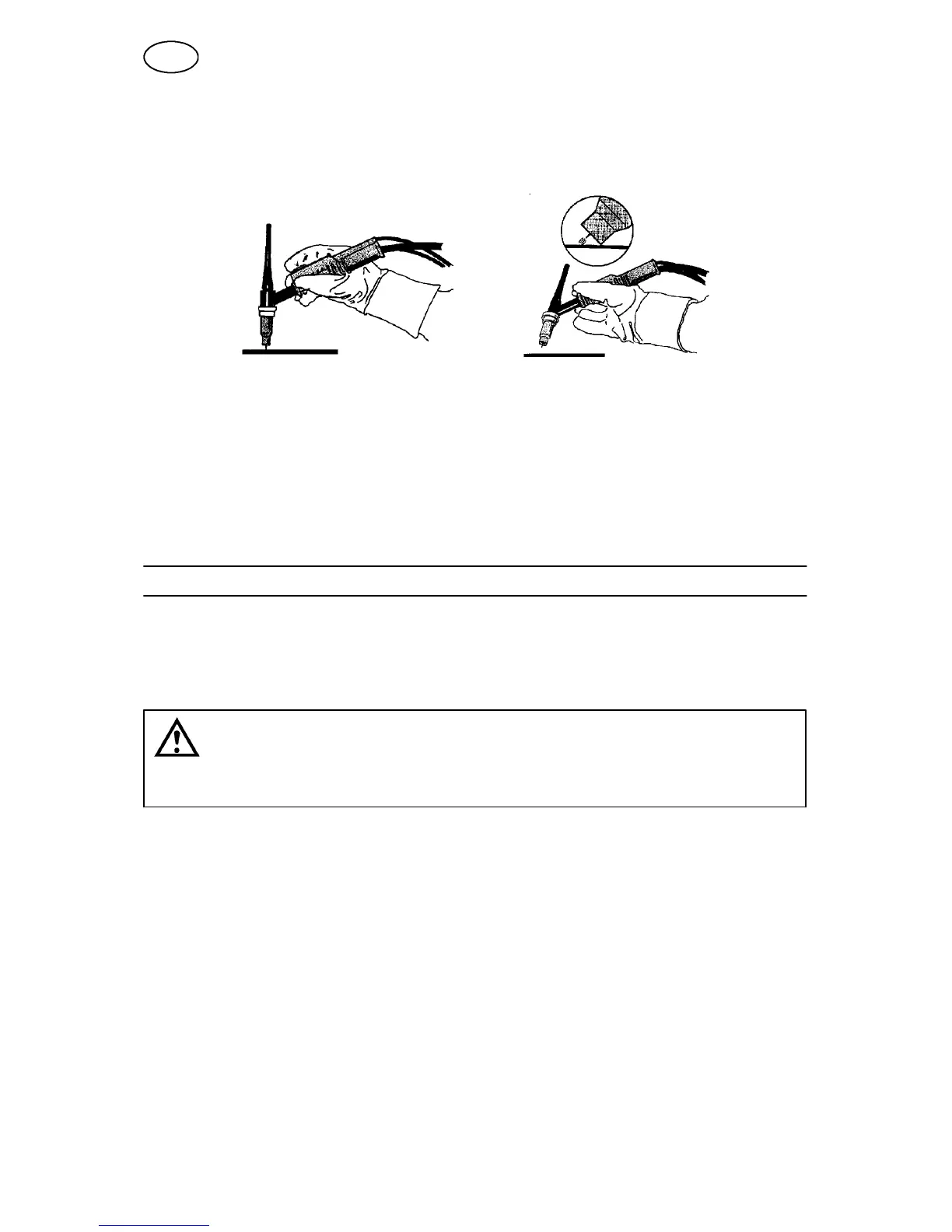

”Live TIG--start”

At a ” Live T IG--start” the tungsten electrode is placed against the workpiece. When

the electrode is then lifted away from workpiece, the arc is struck at a limited current

level (12 -- 15 A).

6.7 MMA welding

For welding with coated electrodes, the power source is supplemented with:

S welding cable with electrode clamp

7 MAINTENANCE

Regular maintenance is important for safe, reliable operation.

Only personnel with the appropriate electrical skills (authorised staff) may r em ove

safety plates.

CAUTION!

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any faults.

7.1 Power source

Check regularly that the welding power source is not clogged with dirt.

How often and which cleaning methods apply depend on: the welding process, arc

times, placement and the surrounding environment. It is normally sufficient to blow

the power source clean with dry compressed air (reduced pressure) once a year.

Clogged or blocked air inlets and outlets otherwise result in overheating.

7.2 Welding torch

Wear parts should be cleaned and replaced at regular intervals in order to achieve

trouble--free welding.

GB

Loading...

Loading...