11

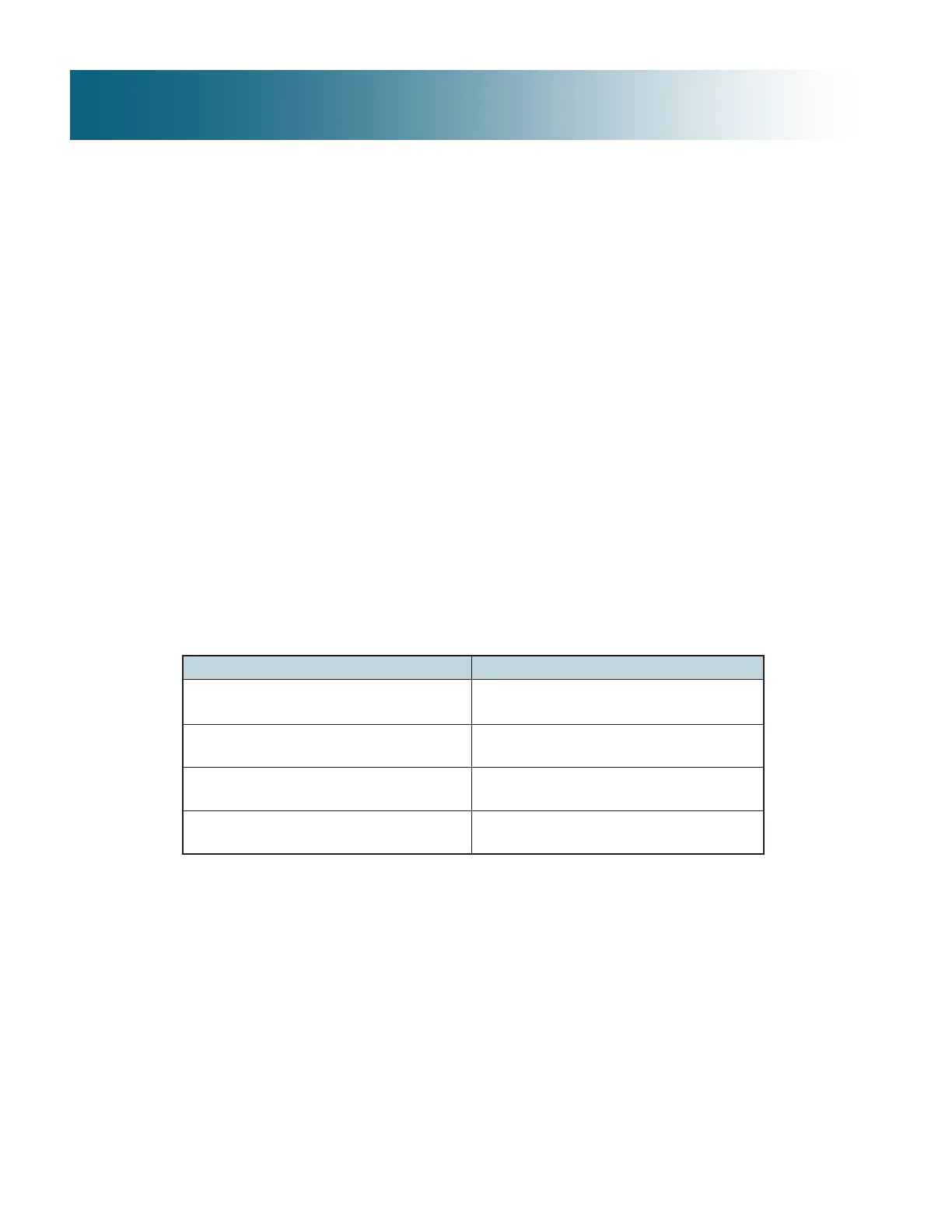

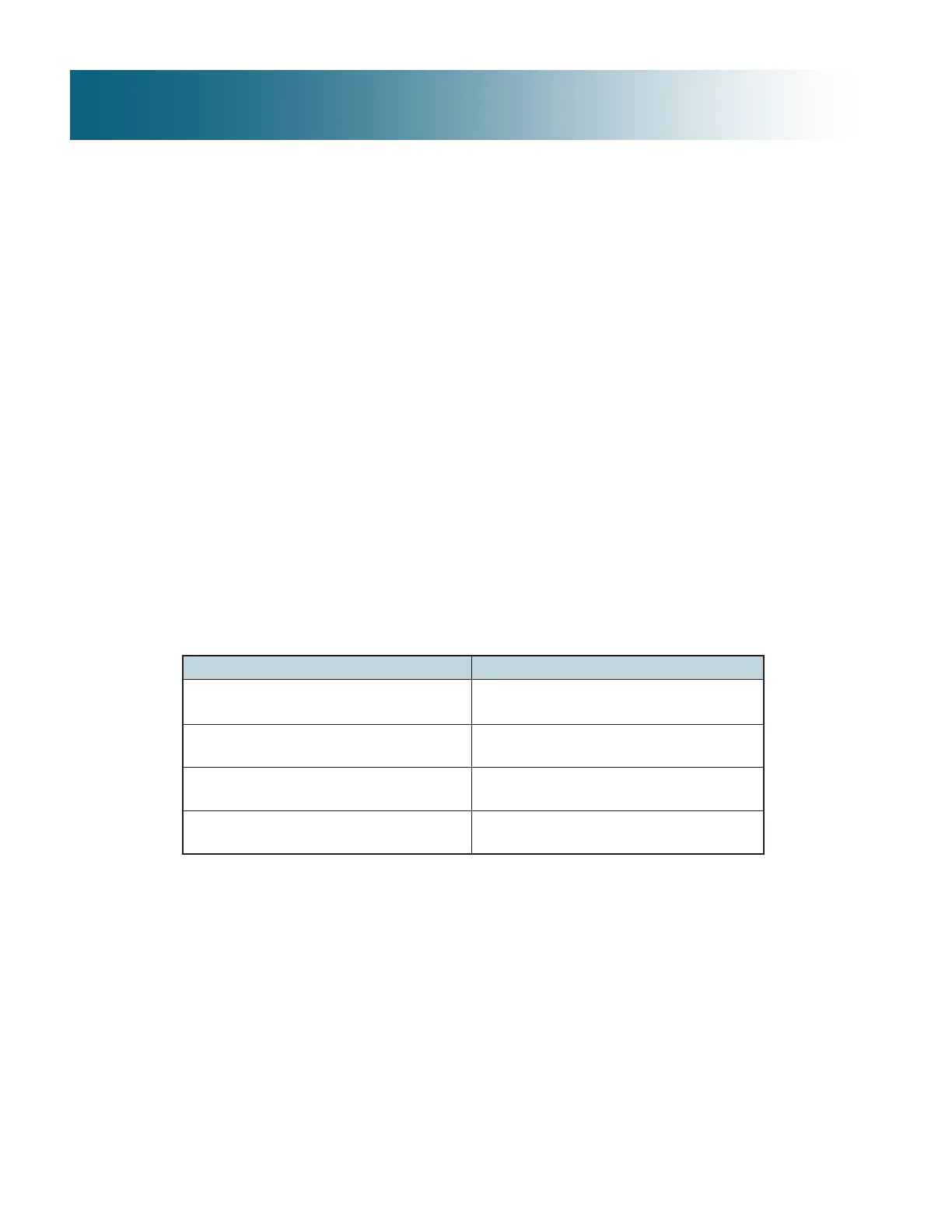

Table 1 – Location of Grease Lube Line Fittings for Belt Driven Units

Unit Description Location of Lube Line Fittings

Induced Dra Units: Located just beside the fan casing

3’, 4’, 8’, 8.5’, 17’ wide access door

Induced Dra Units: Located inside the fan casing

10’, 12’, 14’, 24’, 28’ wide access door

Forced Dra Units Located on the bearing support or

on the side of the unit

PHC Units Located inside access door at bottom of

casing/above the field seam

The fan systems of both centrifugal and axial driven units are rugged; however, the fan system must be checked regularly and lubricated at

the proper intervals. The following maintenance schedule is recommended.

Fan Motor Bearings

E

VAPCO evaporative cooling units use either a T.E.A.O. (Totally Enclosed Air Over) or a T.E.F.C. (Totally Enclosed Fan Cooled) fan motor.

These motors are built to “Cooling Tower Duty” specifications. They are supplied with permanently lubricated bearings and special

moisture protection on the bearings, sha and windings. Aer extended shut-downs, the motor should be checked with an insulation

tester prior to restarting the motor.

Fan Sha Ball Bearings

For induced dra units, lubricate the fan sha bearings every 1,000 hours of operation or every three months. For forced dra units,

lubricate the fan sha bearings every 2,000 hours of operation or every six months. Use any of the following synthetic waterproof, polyurea

inhibited greases which are suitable for operation between -20°F and 350°F. (For colder operating temperatures, contact the factory).

Mobil – Polyrex EM Chevron - SRI Timken Pillowblock Grease

Feed grease slowly into the bearings or the seals may be damaged. A hand grease gun is recommended for this process.

When introducing new grease, all grease should be purged from the bearings.

Most EVAPCO units are supplied with extended grease lines to allow easy lubrication of the fan sha bearings as shown in Table 1.

Fan System

Loading...

Loading...