STARTING

AND

OPERATION

TROUBLE

CHECK

CHART

MOTOR WILL NOT STAAT, check for:

1.

ShifVThrottle lever in NEUTRAL

and warm-up lever in

STAAT

position.

2.

Fuel in tank

3. Fuel

line

connector

properly

attached

4. Fuel line primer bulb at tank end

5. Carburetor primed (squeeze primer

bulb)

6.

Fu

el tank

re

sting

on

fuel line

7.

Fuel

li

ne clear and not kinked

8. Cold motor: Engine not choked

sufficiently

9. Wa

rm

motor: .Engine over-choked

or

flooded. (Do not choke

motor

,

disconnect fuel

line at

motor

, and

crank until cleared.)

10

. Fuel pu

mp

filter obstructed

11

. Water in fuel system

12

.

Check

battery

and

electrical

connections

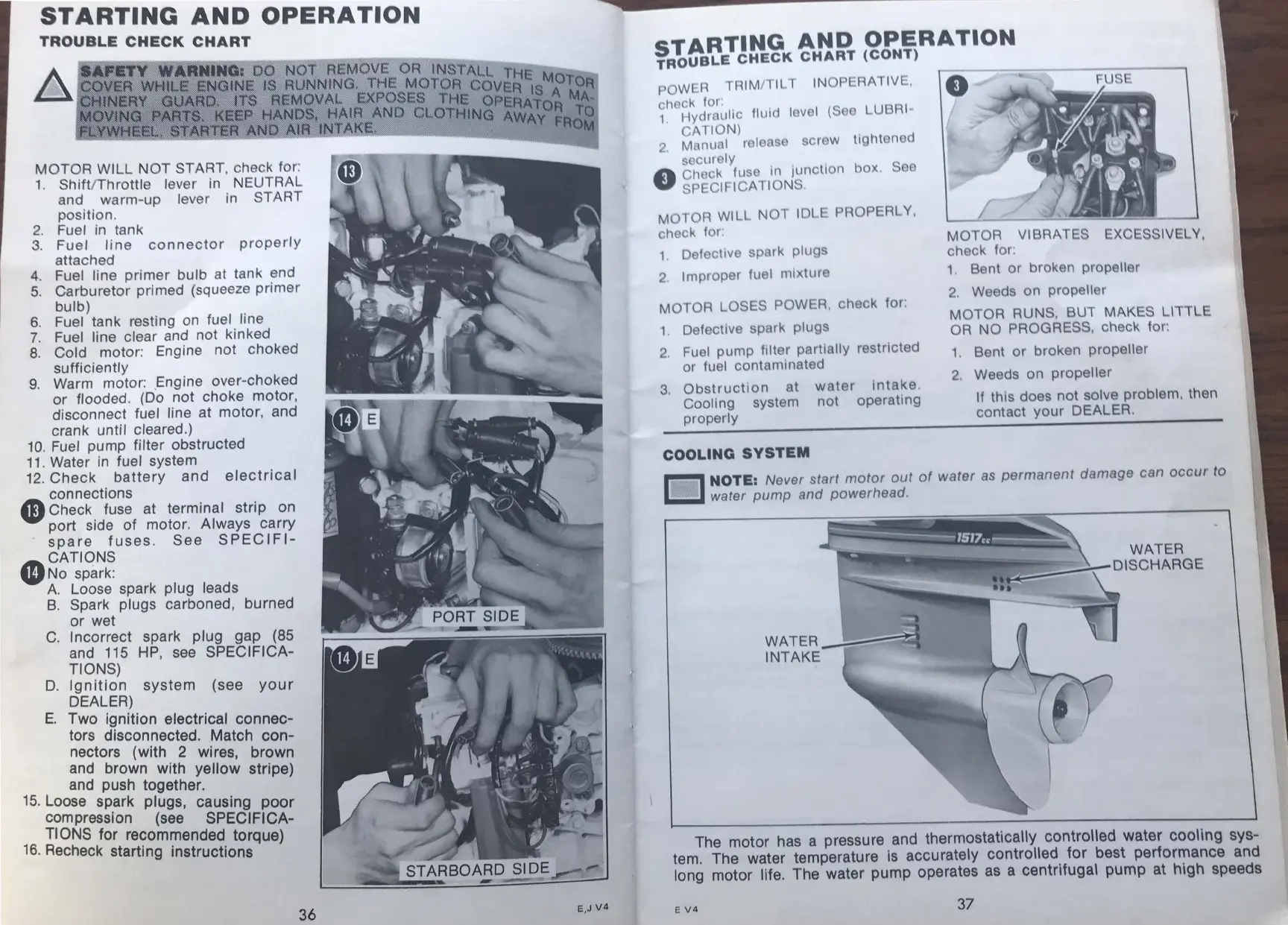

Q»

Check fuse at terminal strip on

port side

of

motor. Always carry

spare

fuses

.

See

SPECIFI

-

CATIONS

G)No

spark:

A Loose spark plug leads

B.

Spark plugs carboned, burned

or

wet

C.

Incorrect spark plug gap (85

and

115

HP, see SPECIFICA-

TIONS)

D.

Ignition

system

(see

your

DEALER)

E.

Two ignition electrical

connec-

tors disconnected. Match

con-

nectors (with 2 wires, brown

and brown with yellow stripe)

and push together.

15.

Loose spark plugs, causing

poor

compression (see SPECIFICA-

TIONS

for recommended torque)

16

. Recheck starting instructions

36

E,J

V4

ST

A

RT

IN

G

AND

OPERATI

ON

TROUBLE

CHECK

CHART

(CONT)

POW

R

TR

IM/TIL

IN

OPERAT

I

VE,

ch

ck

for

:

1. Hydr

LJIIc

flltid I v I

(S

LUBR

I-

CATION)

2.

M

nu

1 r I s cr w ti hl n d

cur ly

A

Ch

ck

fu

in

junction box. S

V SPECIFICATIONS.

MOTOR

WILL N

OT

I

DLE

PROPERLY,

check for.

1 Defective

sp

rk

plugs

2. Improper

fu

I

mi

ture

MOTOR

LOSES

PO

W

ER,

check for:

1.

Defec

t

ive

spark plugs

2.

Fu

el

pu

mp filter partl lly restricted

or

fu

el contaminated

3.

Obstruction

at wa

ter

Intake.

Cooling

system not operating

properly

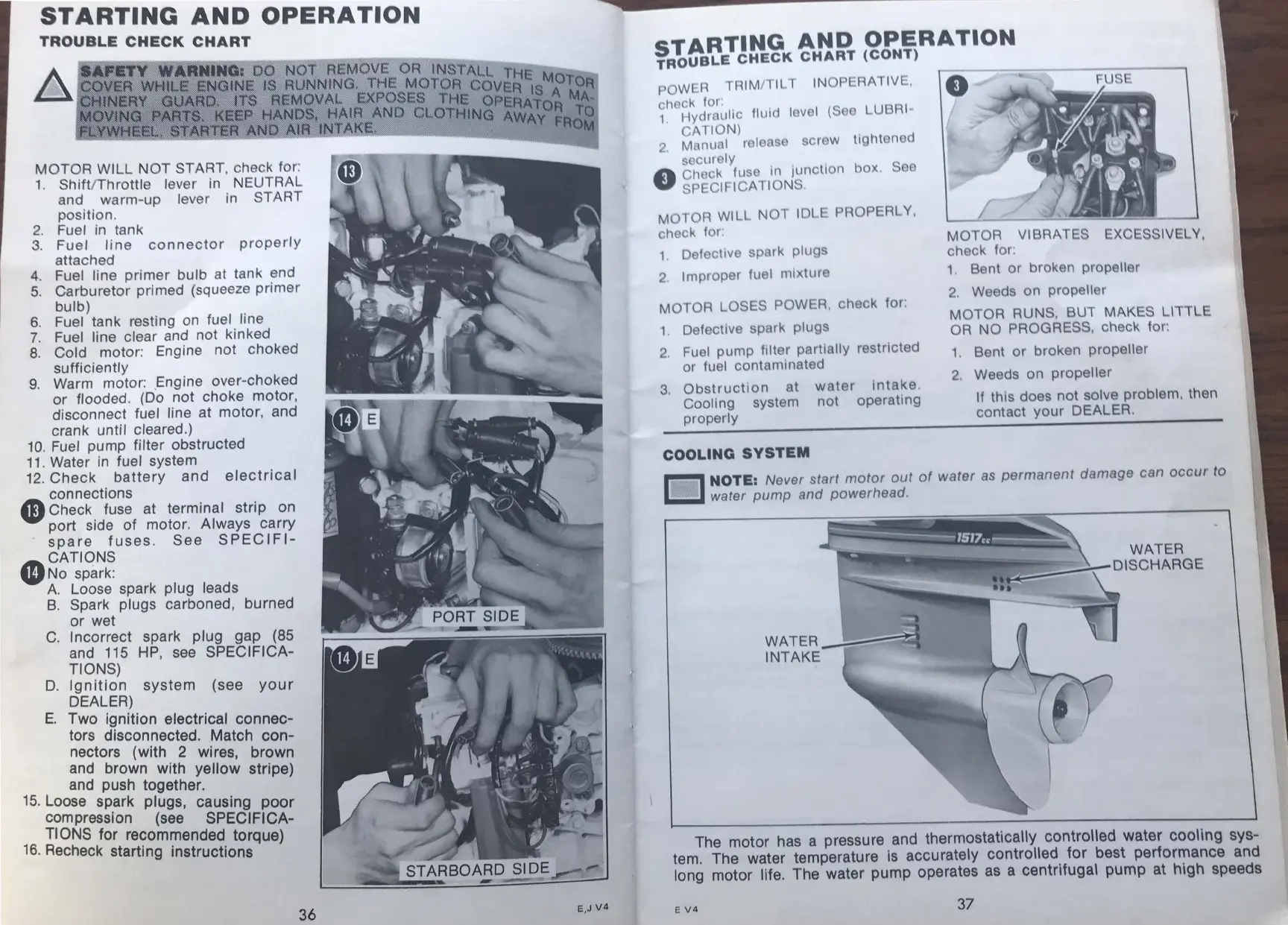

COOLING

SYSTEM

-

0

MOTOR

VI

B

RA

TE

S EX

CE

SS

I

VELY

ch ck for: '

1. Bent or broken prop

II

r

2.

We

e

ds

on propell

er

MOTOR RUNS, BUT MAKES LITTLE

OR

NO PROGRESS, check for:

1. Bent or broken

propeller

2.

Weeds on propeller

If

this does not solve problem, then

contact your DEALER.

~

NOTE: Never start

motor

out

of

water

as

permanent

damage can

occur

to

~

water

pump

and powerhead.

WATER

INTAKE

The motor has a pressure and thermostatically

controlled

water

cooling

sys-

tem. The water temperature is accurately controlled

for

best

performance

and

long motor life. The water pump operates

as

a centrifugal

pump

at

high

speeds

E

V4

37

Loading...

Loading...